NOTE: All dimensions are in inches (mm).

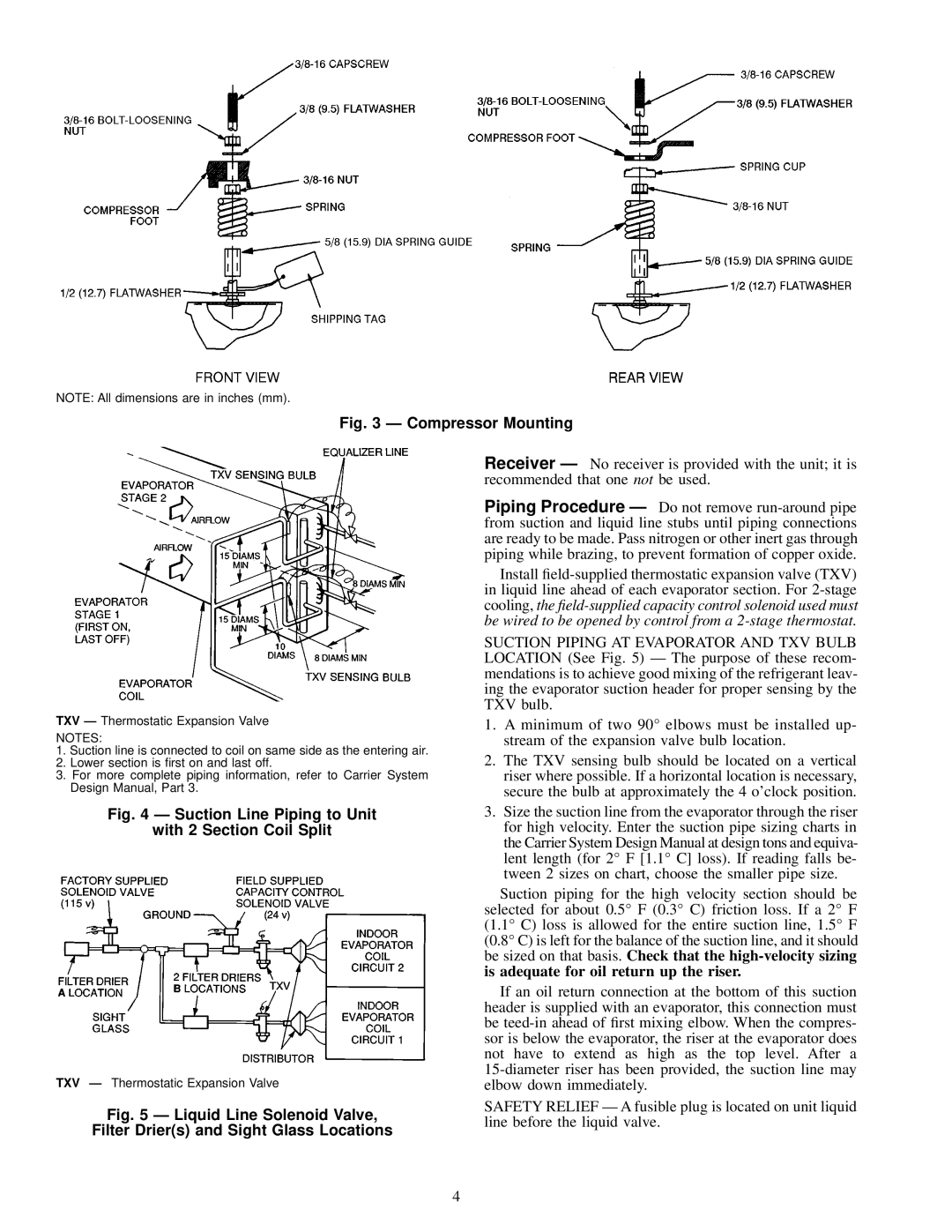

Fig. 3 Ð Compressor Mounting

TXV Ð Thermostatic Expansion Valve

NOTES:

1.Suction line is connected to coil on same side as the entering air.

2.Lower section is ®rst on and last off.

3.For more complete piping information, refer to Carrier System Design Manual, Part 3.

Fig. 4 Ð Suction Line Piping to Unit

with 2 Section Coil Split

TXV Ð Thermostatic Expansion Valve

Fig. 5 Ð Liquid Line Solenoid Valve,

Filter Drier(s) and Sight Glass Locations

Receiver Ð No receiver is provided with the unit; it is recommended that one not be used.

Piping Procedure Ð Do not remove

Install

SUCTION PIPING AT EVAPORATOR AND TXV BULB LOCATION (See Fig. 5) Ð The purpose of these recom- mendations is to achieve good mixing of the refrigerant leav- ing the evaporator suction header for proper sensing by the TXV bulb.

1.A minimum of two 90° elbows must be installed up- stream of the expansion valve bulb location.

2.The TXV sensing bulb should be located on a vertical riser where possible. If a horizontal location is necessary, secure the bulb at approximately the 4 o'clock position.

3.Size the suction line from the evaporator through the riser for high velocity. Enter the suction pipe sizing charts in the Carrier System Design Manual at design tons and equiva- lent length (for 2° F [1.1° C] loss). If reading falls be- tween 2 sizes on chart, choose the smaller pipe size.

Suction piping for the high velocity section should be selected for about 0.5° F (0.3° C) friction loss. If a 2° F (1.1° C) loss is allowed for the entire suction line, 1.5° F (0.8° C) is left for the balance of the suction line, and it should be sized on that basis. Check that the

If an oil return connection at the bottom of this suction header is supplied with an evaporator, this connection must be

SAFETY RELIEF Ð A fusible plug is located on unit liquid line before the liquid valve.

4