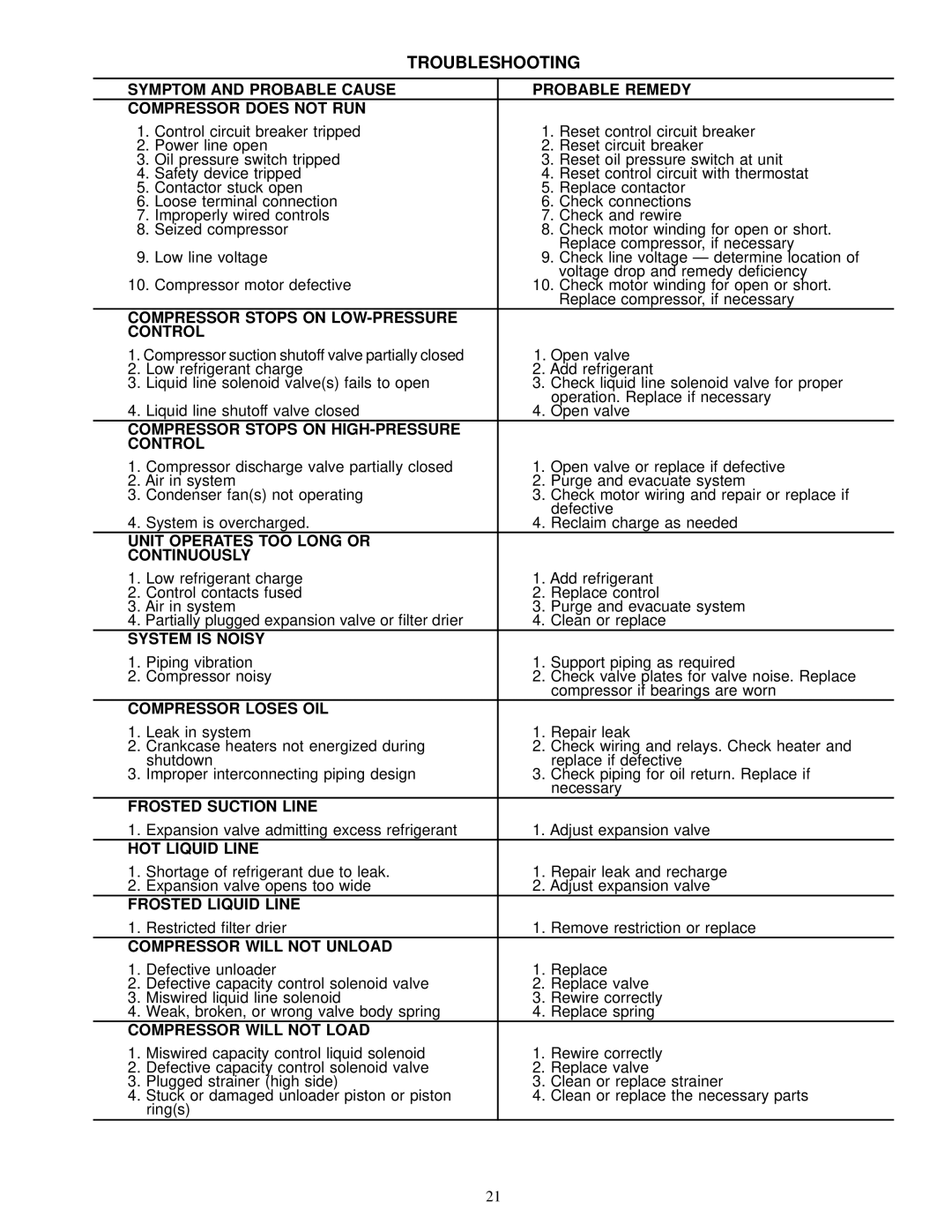

| TROUBLESHOOTING | ||

SYMPTOM AND PROBABLE CAUSE | PROBABLE REMEDY | ||

COMPRESSOR DOES NOT RUN |

|

| |

1. Control circuit breaker tripped | 1. Reset control circuit breaker | ||

2. Power line open | 2. Reset circuit breaker | ||

3. Oil pressure switch tripped | 3. Reset oil pressure switch at unit | ||

4. Safety device tripped | 4. Reset control circuit with thermostat | ||

5. Contactor stuck open | 5. Replace contactor | ||

6. Loose terminal connection | 6. Check connections | ||

7. Improperly wired controls | 7. Check and rewire | ||

8. Seized compressor | 8. Check motor winding for open or short. | ||

9. Low line voltage |

| Replace compressor, if necessary | |

9. Check line voltage Ð determine location of | |||

10. Compressor motor defective |

| voltage drop and remedy de®ciency | |

10. Check motor winding for open or short. | |||

|

|

| Replace compressor, if necessary |

COMPRESSOR STOPS ON |

|

| |

CONTROL |

|

| |

1. Compressor suction shutoff valve partially closed | 1. Open valve | ||

2. | Low refrigerant charge | 2. | Add refrigerant |

3. | Liquid line solenoid valve(s) fails to open | 3. | Check liquid line solenoid valve for proper |

4. | Liquid line shutoff valve closed | 4. | operation. Replace if necessary |

Open valve | |||

COMPRESSOR STOPS ON |

|

| |

CONTROL |

|

| |

1. | Compressor discharge valve partially closed | 1. | Open valve or replace if defective |

2. | Air in system | 2. | Purge and evacuate system |

3. | Condenser fan(s) not operating | 3. | Check motor wiring and repair or replace if |

4. | System is overcharged. | 4. | defective |

Reclaim charge as needed | |||

UNIT OPERATES TOO LONG OR |

|

| |

CONTINUOUSLY |

|

| |

1. | Low refrigerant charge | 1. | Add refrigerant |

2. | Control contacts fused | 2. | Replace control |

3. | Air in system | 3. | Purge and evacuate system |

4. | Partially plugged expansion valve or ®lter drier | 4. Clean or replace | |

SYSTEM IS NOISY |

|

| |

1. | Piping vibration | 1. | Support piping as required |

2. | Compressor noisy | 2. | Check valve plates for valve noise. Replace |

|

|

| compressor if bearings are worn |

COMPRESSOR LOSES OIL |

|

| |

1. | Leak in system | 1. | Repair leak |

2. | Crankcase heaters not energized during | 2. | Check wiring and relays. Check heater and |

3. | shutdown | 3. | replace if defective |

Improper interconnecting piping design | Check piping for oil return. Replace if | ||

|

|

| necessary |

FROSTED SUCTION LINE |

|

| |

1. | Expansion valve admitting excess refrigerant | 1. | Adjust expansion valve |

HOT LIQUID LINE |

|

| |

1. | Shortage of refrigerant due to leak. | 1. | Repair leak and recharge |

2. | Expansion valve opens too wide | 2. | Adjust expansion valve |

FROSTED LIQUID LINE |

|

| |

1. | Restricted ®lter drier | 1. Remove restriction or replace | |

COMPRESSOR WILL NOT UNLOAD |

|

| |

1. | Defective unloader | 1. | Replace |

2. | Defective capacity control solenoid valve | 2. | Replace valve |

3. | Miswired liquid line solenoid | 3. | Rewire correctly |

4. | Weak, broken, or wrong valve body spring | 4. | Replace spring |

COMPRESSOR WILL NOT LOAD |

|

| |

1. | Miswired capacity control liquid solenoid | 1. | Rewire correctly |

2. | Defective capacity control solenoid valve | 2. | Replace valve |

3. | Plugged strainer (high side) | 3. | Clean or replace strainer |

4. | Stuck or damaged unloader piston or piston | 4. | Clean or replace the necessary parts |

| ring(s) |

|

|

21