38BYG, 38BYC specifications

The Carrier 38BYC and 38BYG are part of Carrier's innovative range of commercial HVAC systems, specifically engineered to offer superior cooling and heating solutions. With their modular design, these units cater to a variety of commercial applications, providing energy-efficient climate control that meets the diverse needs of businesses.One of the standout features of the Carrier 38BYC and 38BYG is the incorporation of advanced inverter technology. This technology allows the system to adjust its compressor speed in real time, optimizing energy consumption while ensuring consistent indoor comfort. This capability significantly reduces operational costs compared to traditional HVAC systems that operate at fixed speeds.

Both models boast enhanced cooling and heating capabilities with high energy efficiency ratings, helping businesses reduce their carbon footprint while enjoying substantial savings on energy bills. The efficiency is further reinforced by the use of environmentally friendly refrigerants, aligning with global efforts to minimize the impact of refrigeration technologies on the environment.

Another key characteristic of the 38BYC and 38BYG is their quiet operation. Engineered with sound-dampening features, these units provide a comfortable indoor experience without the disruptive noise often associated with HVAC systems. This makes them particularly suitable for commercial spaces where a peaceful environment is crucial, such as offices, hotels, and healthcare facilities.

Connectivity is a significant aspect of these models. Equipped with smart technology, the Carrier 38BYC and 38BYG support remote monitoring and control through mobile applications. This allows facility managers to adjust settings, monitor performance, and schedule maintenance tasks from virtually anywhere, enhancing operational efficiency and convenience.

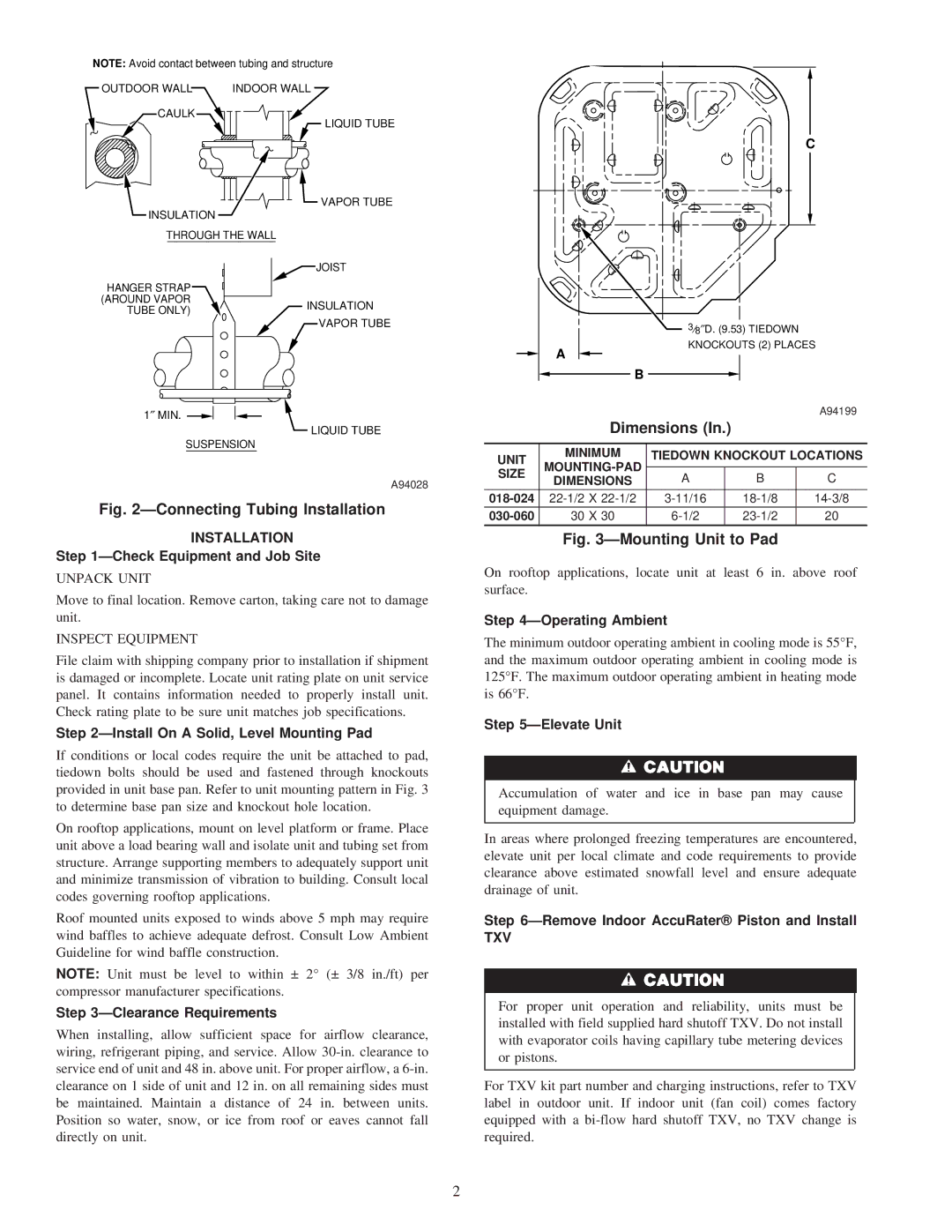

In terms of installation and maintenance, both models are designed with ease of access in mind. The modular design simplifies installation and servicing, ensuring that downtime is minimized, and system longevity is maximized. Their compact footprint makes them versatile enough to fit in various architectural spaces, making them an ideal choice for retrofitting or new constructions.

Overall, the Carrier 38BYC and 38BYG systems encapsulate modern HVAC technology with their emphasis on energy efficiency, quiet operation, smart connectivity, and ease of maintenance. These traits not only serve businesses’ immediate cooling and heating needs but also contribute to a more sustainable and cost-effective future. Whether for a small office or a large commercial establishment, these units deliver a comprehensive climate control solution tailored for today’s ever-evolving business landscape.