Cylinder Heads (See Fig. 11) — Disassemble cyl- inder heads by removing cap screws, and prying up on side lifting tabs to break heads loose from valve plates. Do not hit cylinder heads to break loose.

Check heads for warping, cracks and damage to gasket surfaces. When replacing cylinder head, torque cap screws 90 to 100

Pressure Relief Valve — This internal safety device is located in center cylinder bank

Suction and Discharge Valve Plate Assembly

TEST — Leak test for leaking discharge valves by pumping compressor down and observing suction and discharge pres- sure equalization. If a discharge valve is leaking, pressures will equalize rapidly. Maximum allowable discharge pressure drop is 3 psi per minute.

If there is an indicated loss of capacity and discharge valves check properly, remove suction and discharge valve plate assembly and inspect suction valves.

DISASSEMBLE — Remove cylinder head.

1.Remove discharge valve assembly: cap screws, valve stops, valve stop supports and valves.

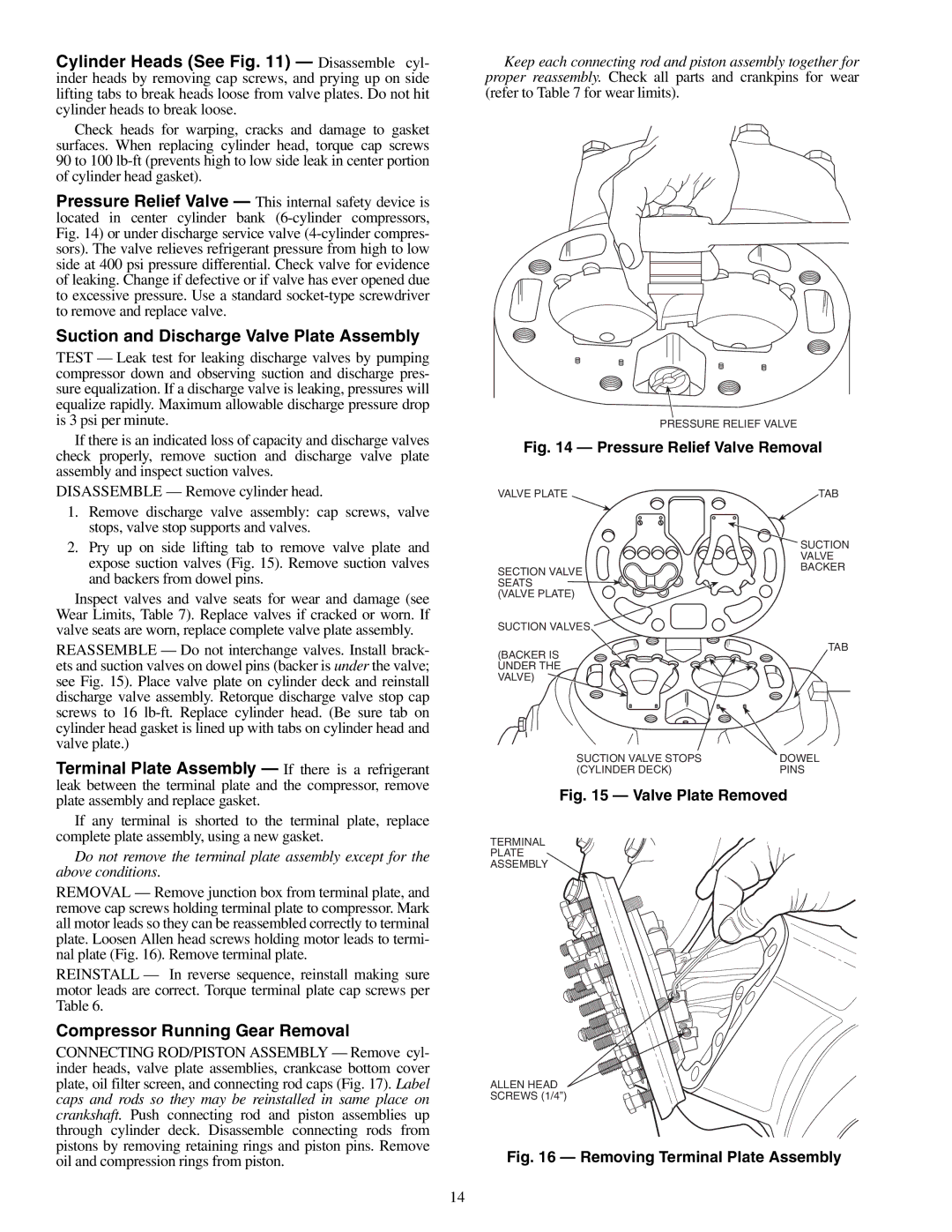

2.Pry up on side lifting tab to remove valve plate and expose suction valves (Fig. 15). Remove suction valves and backers from dowel pins.

Inspect valves and valve seats for wear and damage (see Wear Limits, Table 7). Replace valves if cracked or worn. If valve seats are worn, replace complete valve plate assembly.

REASSEMBLE — Do not interchange valves. Install brack- ets and suction valves on dowel pins (backer is under the valve; see Fig. 15). Place valve plate on cylinder deck and reinstall discharge valve assembly. Retorque discharge valve stop cap screws to 16

Terminal Plate Assembly — If there is a refrigerant leak between the terminal plate and the compressor, remove plate assembly and replace gasket.

If any terminal is shorted to the terminal plate, replace complete plate assembly, using a new gasket.

Do not remove the terminal plate assembly except for the above conditions.

REMOVAL — Remove junction box from terminal plate, and remove cap screws holding terminal plate to compressor. Mark all motor leads so they can be reassembled correctly to terminal plate. Loosen Allen head screws holding motor leads to termi- nal plate (Fig. 16). Remove terminal plate.

REINSTALL — In reverse sequence, reinstall making sure motor leads are correct. Torque terminal plate cap screws per Table 6.

Compressor Running Gear Removal

CONNECTING ROD/PISTON ASSEMBLY — Remove cyl- inder heads, valve plate assemblies, crankcase bottom cover plate, oil filter screen, and connecting rod caps (Fig. 17). Label caps and rods so they may be reinstalled in same place on crankshaft. Push connecting rod and piston assemblies up through cylinder deck. Disassemble connecting rods from pistons by removing retaining rings and piston pins. Remove oil and compression rings from piston.

Keep each connecting rod and piston assembly together for proper reassembly. Check all parts and crankpins for wear (refer to Table 7 for wear limits).

PRESSURE RELIEF VALVE | |

Fig. 14 — Pressure Relief Valve Removal | |

VALVE PLATE | TAB |

| SUCTION |

| VALVE |

SECTION VALVE | BACKER |

| |

SEATS |

|

(VALVE PLATE) |

|

SUCTION VALVES |

|

(BACKER IS | TAB |

| |

UNDER THE |

|

VALVE) |

|

SUCTION VALVE STOPS | DOWEL |

(CYLINDER DECK) | PINS |

Fig. 15 — Valve Plate Removed

TERMINAL

PLATE

ASSEMBLY

ALLEN HEAD

SCREWS (1/4”)

Fig. 16 — Removing Terminal Plate Assembly

14