then temperature at which first stage will be shut down will be offset 5°F above limit value (110°F to 114°F). If limit temperature is between 110°F and 155°F, then temperature at which first stage will shut down will be offset 20°F above limit value (130°F to 175°F). For Cooling modes the temperature is fixed at 50°F (10°C) for starting the control and 45°F (7.2°C) for turning off first-stage cooling.

The heating value must be set given the type of heater used in the system. This is for the final heat source. So a heat pump with strip heat would use a temperature appropriate for strip heaters. A furnace application may have a setting in the 130°F to 155°F range. Strip heaters may fall into a 115°F to 130°F range. Heat pump only systems may use 105°F to 115°F. Check equipment manufacturer recommendations and verify setting is in accordance with UL, NFPA, or any applicable Local or State Building Codes. If there is any question about what may be an appropriate temperature setting, use conservative (low) temperatures.

Dx Coil Sensor For Leaving Air Temperature (Rotary Position T-27) allows Comfort Zone to use a Dx Coil Sensor in addition to Remote Duct Sensor for Leaving Air Temperature Checking. The Dx Coil Sensor is used in heat pumps with fan coil applications and will be located after the Dx coil and before any strip heaters. This sensor is only active during heat pump operation. The temperature setting for this sensor is fixed at 105°F for initiating the control option and 110°F for shutting down first stage.

Heat Pump-Strip Heat Economy Feature (Smart Start). This is an automatic control within Comfort Zone and not a selectable option. The Smart Start feature is used whenever primary source of heat is a heat pump. As such, the Heat Pump toggle (Rotary Position T-6) must be turned ON. Smart Start is designed to help minimize use of strip heat or emergency heat whenever a large heating demand occurs due to a scheduled setpoint change. Smart Start looks at scheduled comfort setpoints for the next hour. If scheduled setpoints will make system provide heat, Smart Start will start heat pump an hour early. Smart Start will operate until zone demand is brought within 0.5°F (0.28°C) of the next hour's heat setpoint or setpoints change due to the schedule (the hour expires).

Smart Start assumes auxiliary heat is more expensive to operate when compared to heat pump and it assumes that heat pump is a relatively "slow" source of heat. Smart Start allows a zone to recover from a setback or unoccupied period and use the most economic source of heat in doing so. The idea of using a setback or unoccupied schedule is to save money in operating costs. There is little incentive to use schedules if zone is heated with most expensive source of heat available.

Step 11ÐConfiguring Four Zone Controller

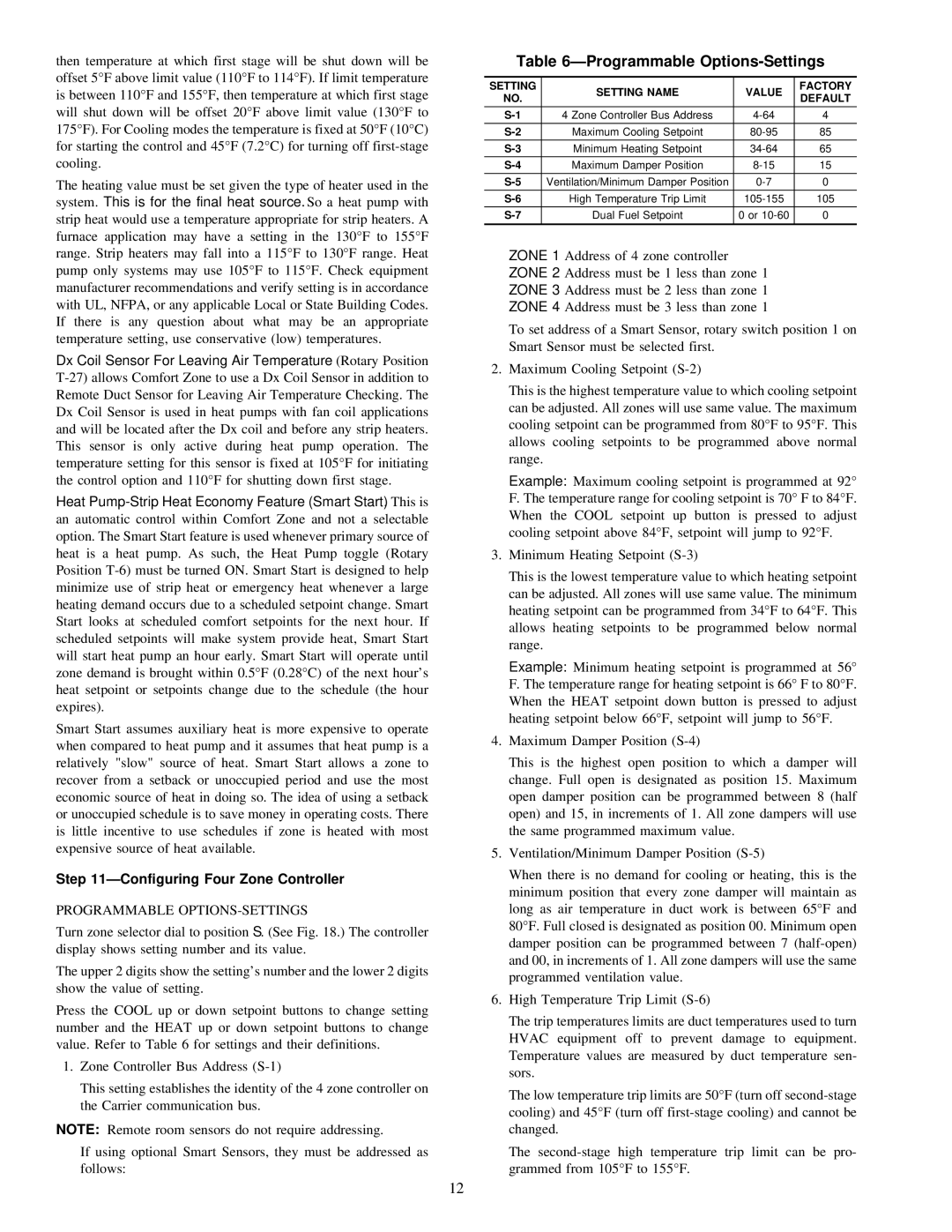

PROGRAMMABLE OPTIONS-SETTINGS

Turn zone selector dial to position S. (See Fig. 18.) The controller display shows setting number and its value.

The upper 2 digits show the setting's number and the lower 2 digits show the value of setting.

Press the COOL up or down setpoint buttons to change setting number and the HEAT up or down setpoint buttons to change value. Refer to Table 6 for settings and their definitions.

1.Zone Controller Bus Address (S-1)

This setting establishes the identity of the 4 zone controller on the Carrier communication bus.

NOTE: Remote room sensors do not require addressing.

If using optional Smart Sensors, they must be addressed as follows:

Table 6ÐProgrammable Options-Settings

| SETTING | SETTING NAME | VALUE | FACTORY |

| NO. | DEFAULT |

| | |

| | | | |

| S-1 | 4 Zone Controller Bus Address | 4-64 | 4 |

| S-2 | Maximum Cooling Setpoint | 80-95 | 85 |

| | | | |

| S-3 | Minimum Heating Setpoint | 34-64 | 65 |

| | | | |

| S-4 | Maximum Damper Position | 8-15 | 15 |

| S-5 | Ventilation/Minimum Damper Position | 0-7 | 0 |

| | | | |

| S-6 | High Temperature Trip Limit | 105-155 | 105 |

| | | | |

| S-7 | Dual Fuel Setpoint | 0 or 10-60 | 0 |

| | | | |

ZONE 1 Address of 4 zone controller

ZONE 2 Address must be 1 less than zone 1

ZONE 3 Address must be 2 less than zone 1

ZONE 4 Address must be 3 less than zone 1

To set address of a Smart Sensor, rotary switch position 1 on Smart Sensor must be selected first.

2.Maximum Cooling Setpoint (S-2)

This is the highest temperature value to which cooling setpoint can be adjusted. All zones will use same value. The maximum cooling setpoint can be programmed from 80°F to 95°F. This allows cooling setpoints to be programmed above normal range.

Example: Maximum cooling setpoint is programmed at 92°

F.The temperature range for cooling setpoint is 70° F to 84°F. When the COOL setpoint up button is pressed to adjust cooling setpoint above 84°F, setpoint will jump to 92°F.

3.Minimum Heating Setpoint (S-3)

This is the lowest temperature value to which heating setpoint can be adjusted. All zones will use same value. The minimum heating setpoint can be programmed from 34°F to 64°F. This allows heating setpoints to be programmed below normal range.

Example: Minimum heating setpoint is programmed at 56°

F.The temperature range for heating setpoint is 66° F to 80°F. When the HEAT setpoint down button is pressed to adjust heating setpoint below 66°F, setpoint will jump to 56°F.

4.Maximum Damper Position (S-4)

This is the highest open position to which a damper will change. Full open is designated as position 15. Maximum open damper position can be programmed between 8 (half open) and 15, in increments of 1. All zone dampers will use the same programmed maximum value.

5.Ventilation/Minimum Damper Position (S-5)

When there is no demand for cooling or heating, this is the minimum position that every zone damper will maintain as long as air temperature in duct work is between 65°F and 80°F. Full closed is designated as position 00. Minimum open damper position can be programmed between 7 (half-open) and 00, in increments of 1. All zone dampers will use the same programmed ventilation value.

6.High Temperature Trip Limit (S-6)

The trip temperatures limits are duct temperatures used to turn HVAC equipment off to prevent damage to equipment. Temperature values are measured by duct temperature sen- sors.

The low temperature trip limits are 50°F (turn off second-stage cooling) and 45°F (turn off first-stage cooling) and cannot be changed.

The second-stage high temperature trip limit can be pro- grammed from 105°F to 155°F.