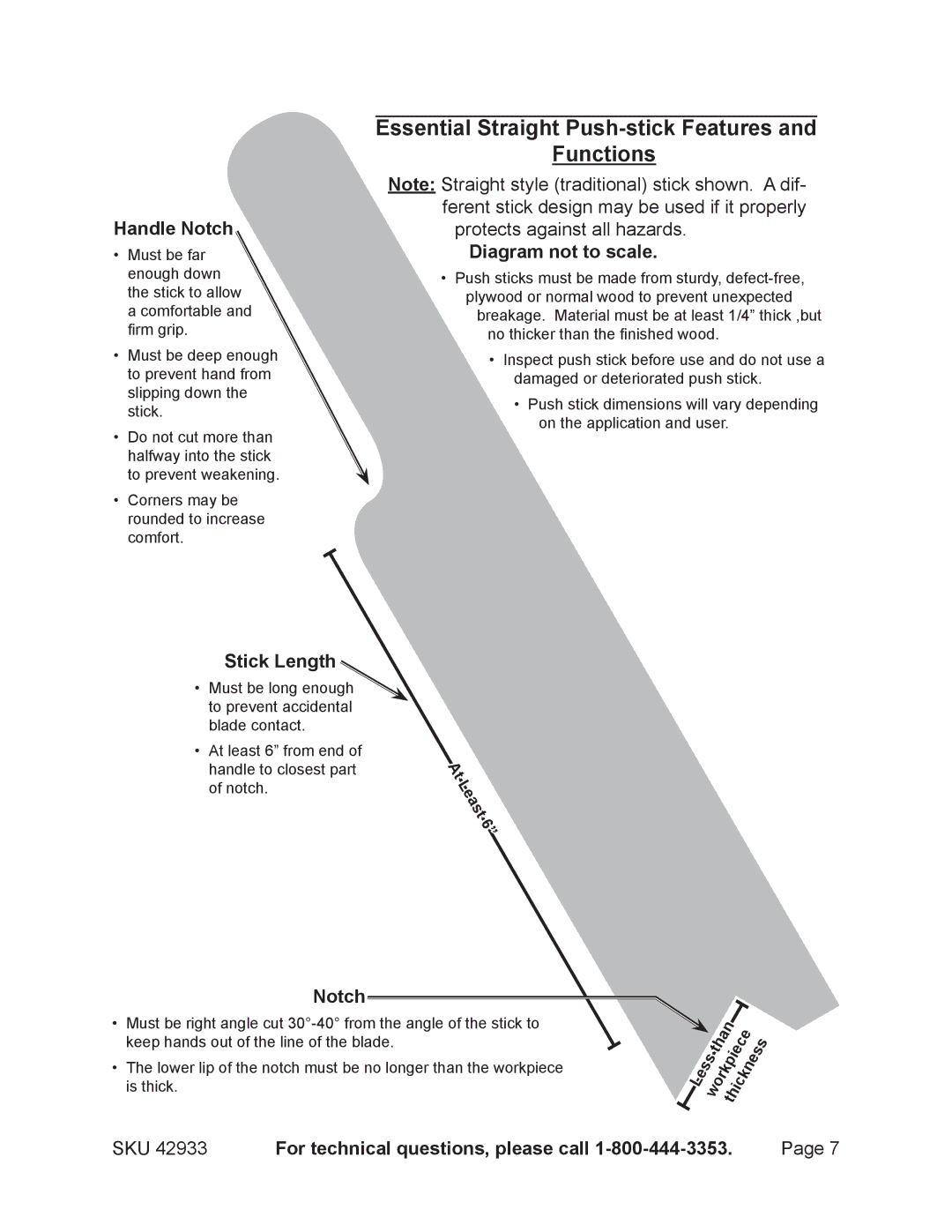

Handle Notch

•Must be far enough down the stick to allow a comfortable and firm grip.

•Must be deep enough to prevent hand from slipping down the stick.

•Do not cut more than halfway into the stick to prevent weakening.

•Corners may be rounded to increase comfort.

Essential Straight Push-stick Features and

Functions

Note: Straight style (traditional) stick shown. A dif- ferent stick design may be used if it properly

protects against all hazards.

Diagram not to scale.

•Push sticks must be made from sturdy,

breakage. Material must be at least 1/4” thick ,but no thicker than the finished wood.

•Inspect push stick before use and do not use a damaged or deteriorated push stick.

•Push stick dimensions will vary depending on the application and user.

Stick Length

•Must be long enough to prevent accidental blade contact.

•At least 6” from end of

handle to closest part | At |

of notch. |

|

Least

6”

Notch

•Must be right angle cut

•The lower lip of the notch must be no longer than the workpiece is thick.

| than |

| workpiece |

Less | thickness |

|

SKU 42933 | For technical questions, please call | Page 7 |