Section 5 - Options

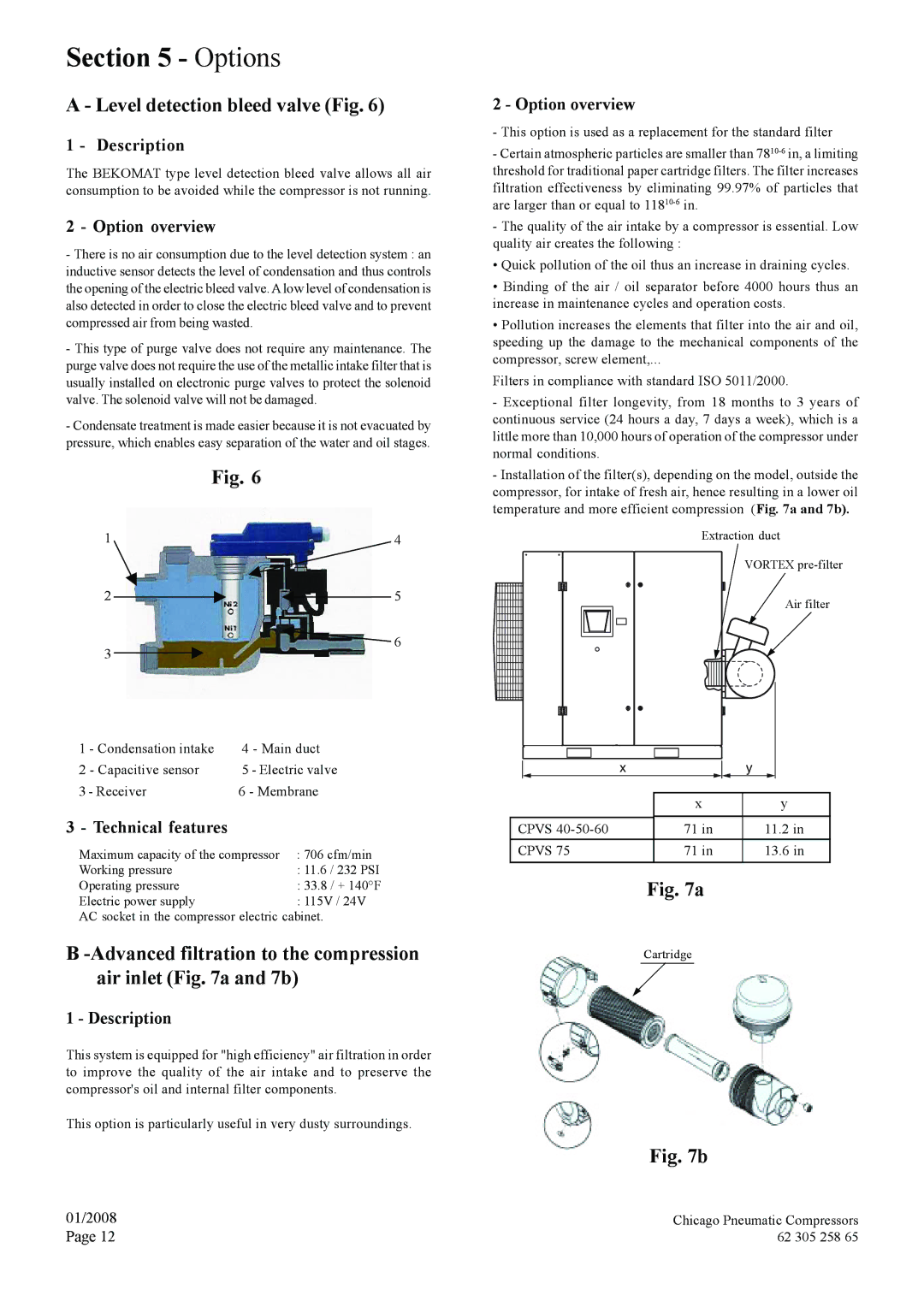

A - Level detection bleed valve (Fig. 6)

1 - Description

The BEKOMAT type level detection bleed valve allows all air consumption to be avoided while the compressor is not running.

2 - Option overview

-There is no air consumption due to the level detection system : an inductive sensor detects the level of condensation and thus controls the opening of the electric bleed valve. A low level of condensation is also detected in order to close the electric bleed valve and to prevent compressed air from being wasted.

-This type of purge valve does not require any maintenance. The purge valve does not require the use of the metallic intake filter that is usually installed on electronic purge valves to protect the solenoid valve. The solenoid valve will not be damaged.

-Condensate treatment is made easier because it is not evacuated by pressure, which enables easy separation of the water and oil stages.

|

|

|

| Fig. 6 | |||

|

|

|

| ||||

1 | 1 |

|

| 44 | |||

2 | 2 |

|

|

|

|

| 55 |

|

|

| |||||

3 | 3 |

|

| 66 | |||

|

|

|

|

|

| ||

|

|

|

|

| |||

|

|

|

|

|

|

|

|

1 - Condensation intake | 4 - Main duct |

2 - Capacitive sensor | 5 - Electric valve |

3 - Receiver | 6 - Membrane |

3 - Technical features

Maximum capacity of the compressor | : 706 cfm/min |

Working pressure | : 11.6 / 232 PSI |

Operating pressure | : 33.8 / + 140°F |

Electric power supply | : 115V / 24V |

AC socket in the compressor electric cabinet.

B -Advanced filtration to the compression air inlet (Fig. 7a and 7b)

1 - Description

This system is equipped for "high efficiency" air filtration in order to improve the quality of the air intake and to preserve the compressor's oil and internal filter components.

This option is particularly useful in very dusty surroundings.

2 - Option overview

-This option is used as a replacement for the standard filter

-Certain atmospheric particles are smaller than

-The quality of the air intake by a compressor is essential. Low quality air creates the following :

• Quick pollution of the oil thus an increase in draining cycles.

•Binding of the air / oil separator before 4000 hours thus an increase in maintenance cycles and operation costs.

•Pollution increases the elements that filter into the air and oil, speeding up the damage to the mechanical components of the compressor, screw element,...

Filters in compliance with standard ISO 5011/2000.

-Exceptional filter longevity, from 18 months to 3 years of continuous service (24 hours a day, 7 days a week), which is a little more than 10,000 hours of operation of the compressor under normal conditions.

-Installation of the filter(s), depending on the model, outside the compressor, for intake of fresh air, hence resulting in a lower oil temperature and more efficient compression (Fig. 7a and 7b).

| Extraction duct | |

|

| VORTEX |

|

| Air filter |

| x | y |

| x | y |

CPVS | 71 in | 11.2 in |

CPVS 75 | 71 in | 13.6 in |

Fig. 7a

Cartridge

Fig. 7b

01/2008 | Chicago Pneumatic Compressors |

Page 12 | 62 305 258 65 |