Section 7 - Maintenance

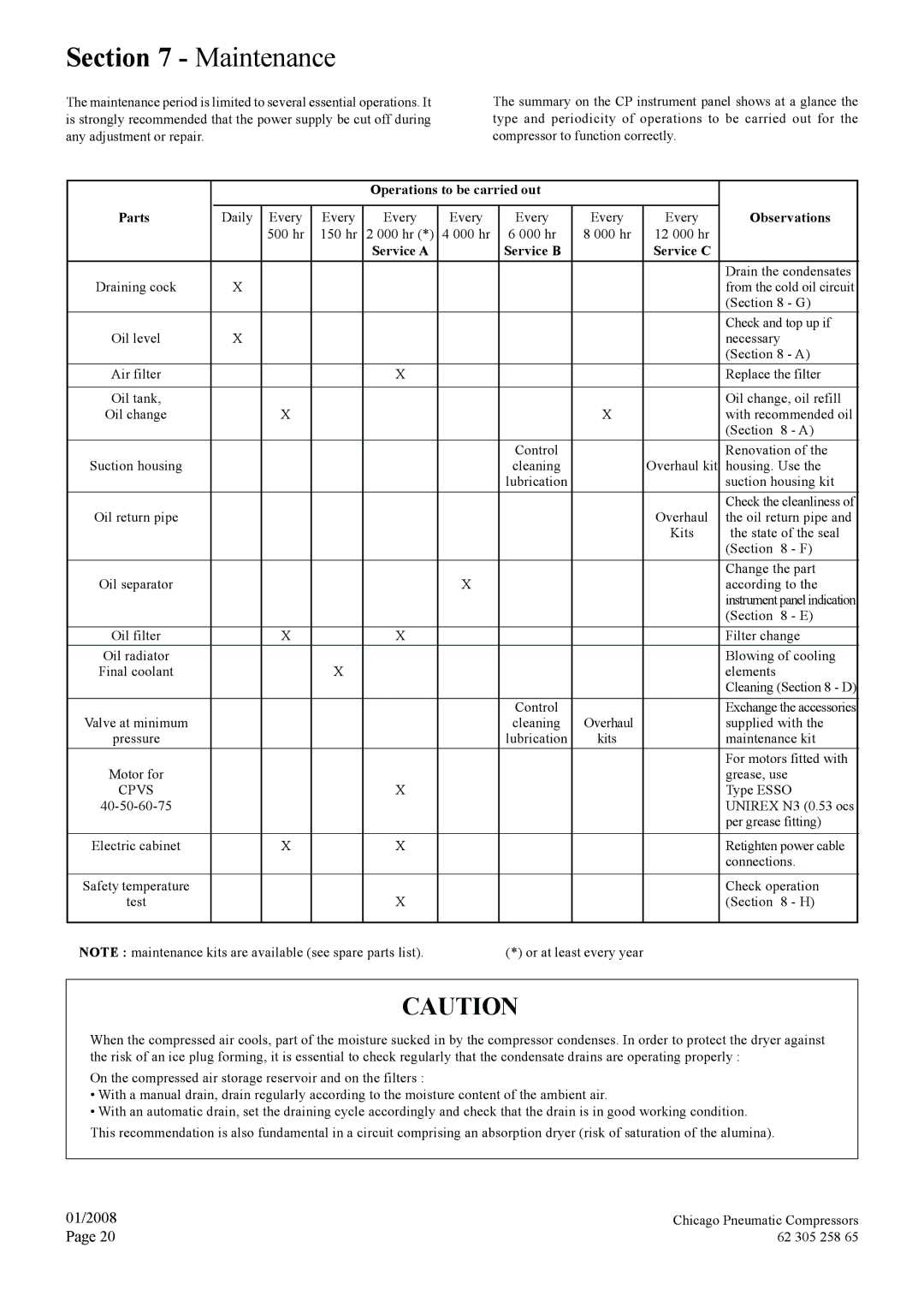

The maintenance period is limited to several essential operations. It is strongly recommended that the power supply be cut off during any adjustment or repair.

The summary on the CP instrument panel shows at a glance the type and periodicity of operations to be carried out for the compressor to function correctly.

|

|

|

| Operations to be carried out |

|

|

| ||

|

|

|

|

|

|

|

|

|

|

Parts | Daily | Every | Every | Every | Every | Every | Every | Every | Observations |

|

| 500 hr | 150 hr | 2 000 hr (*) | 4 000 hr | 6 000 hr | 8 000 hr | 12 000 hr |

|

|

|

|

| Service A |

| Service B |

| Service C |

|

|

|

|

|

|

|

|

|

| Drain the condensates |

Draining cock | X |

|

|

|

|

|

|

| from the cold oil circuit |

|

|

|

|

|

|

|

|

| (Section 8 - G) |

|

|

|

|

|

|

|

|

| Check and top up if |

Oil level | X |

|

|

|

|

|

|

| necessary |

|

|

|

|

|

|

|

|

| (Section 8 - A) |

Air filter |

|

|

| X |

|

|

|

| Replace the filter |

|

|

|

|

|

|

|

|

|

|

Oil tank, |

|

|

|

|

|

|

|

| Oil change, oil refill |

Oil change |

| X |

|

|

|

| X |

| with recommended oil |

|

|

|

|

|

|

|

|

| (Section 8 - A) |

|

|

|

|

|

| Control |

|

| Renovation of the |

Suction housing |

|

|

|

|

| cleaning |

| Overhaul kit | housing. Use the |

|

|

|

|

|

| lubrication |

|

| suction housing kit |

|

|

|

|

|

|

|

|

| Check the cleanliness of |

Oil return pipe |

|

|

|

|

|

|

| Overhaul | the oil return pipe and |

|

|

|

|

|

|

|

| Kits | the state of the seal |

|

|

|

|

|

|

|

|

| (Section 8 - F) |

|

|

|

|

|

|

|

|

| Change the part |

Oil separator |

|

|

|

| X |

|

|

| according to the |

|

|

|

|

|

|

|

|

| instrument panel indication |

|

|

|

|

|

|

|

|

| (Section 8 - E) |

Oil filter |

| X |

| X |

|

|

|

| Filter change |

Oil radiator |

|

|

|

|

|

|

|

| Blowing of cooling |

Final coolant |

|

| X |

|

|

|

|

| elements |

|

|

|

|

|

|

|

|

| Cleaning (Section 8 - D) |

|

|

|

|

|

| Control |

|

| Exchange the accessories |

Valve at minimum |

|

|

|

|

| cleaning | Overhaul |

| supplied with the |

pressure |

|

|

|

|

| lubrication | kits |

| maintenance kit |

|

|

|

|

|

|

|

|

| For motors fitted with |

Motor for |

|

|

|

|

|

|

|

| grease, use |

CPVS |

|

|

| X |

|

|

|

| Type ESSO |

|

|

|

|

|

|

|

| UNIREX N3 (0.53 ocs | |

|

|

|

|

|

|

|

|

| per grease fitting) |

Electric cabinet |

| X |

| X |

|

|

|

| Retighten power cable |

|

|

|

|

|

|

|

|

| connections. |

|

|

|

|

|

|

|

|

|

|

Safety temperature |

|

|

|

|

|

|

|

| Check operation |

test |

|

|

| X |

|

|

|

| (Section 8 - H) |

|

|

|

|

|

|

|

|

|

|

NOTE : maintenance kits are available (see spare parts list). |

| (*) or at least every year |

|

| |||||

CAUTION

When the compressed air cools, part of the moisture sucked in by the compressor condenses. In order to protect the dryer against the risk of an ice plug forming, it is essential to check regularly that the condensate drains are operating properly :

On the compressed air storage reservoir and on the filters :

•With a manual drain, drain regularly according to the moisture content of the ambient air.

•With an automatic drain, set the draining cycle accordingly and check that the drain is in good working condition.

This recommendation is also fundamental in a circuit comprising an absorption dryer (risk of saturation of the alumina).

01/2008 | Chicago Pneumatic Compressors |

Page 20 | 62 305 258 65 |