3

Liquid soap connection (option)

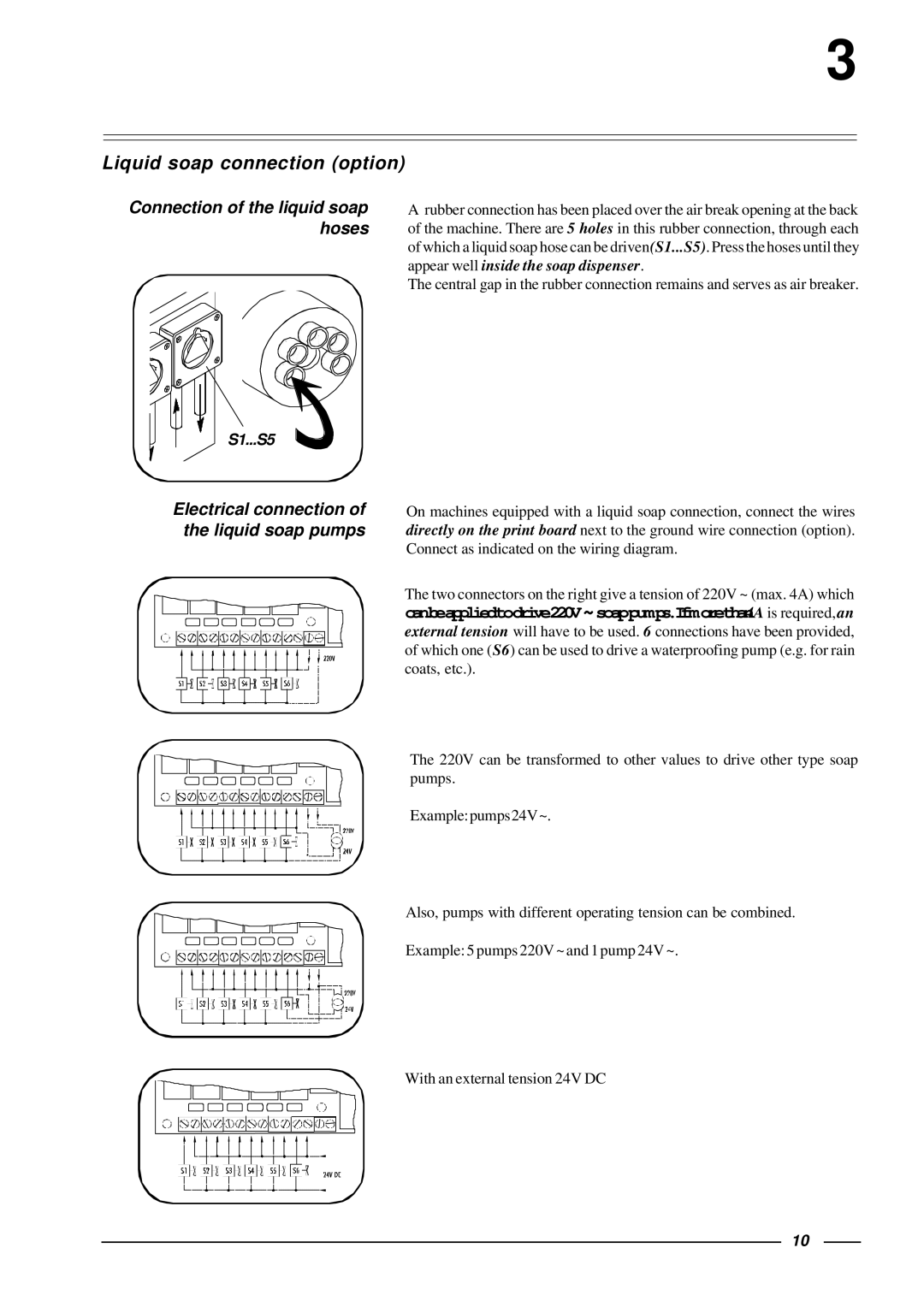

Connection of the liquid soap hoses

Arubber connection has been placed over the air break opening at the back of the machine. There are 5 holes in this rubber connection, through each of which a liquid soap hose can be driven(S1...S5). Press the hoses until they appear well inside the soap dispenser.

The central gap in the rubber connection remains and serves as air breaker.

S1...S5

Electrical connection of the liquid soap pumps

On machines equipped with a liquid soap connection, connect the wires directly on the print board next to the ground wire connection (option). Connect as indicated on the wiring diagram.

The two connectors on the right give a tension of 220V ~ (max. 4A) which canbeappliedtodrive220V ~ soap pumps. Ifmorethan4A is required, an external tension will have to be used. 6 connections have been provided, of which one (S6) can be used to drive a waterproofing pump (e.g. for rain coats, etc.).

The 220V can be transformed to other values to drive other type soap pumps.

Example:pumps24V~.

Also, pumps with different operating tension can be combined.

Example: 5 pumps 220V ~ and 1 pump 24V ~.

With an external tension 24V DC

10