0

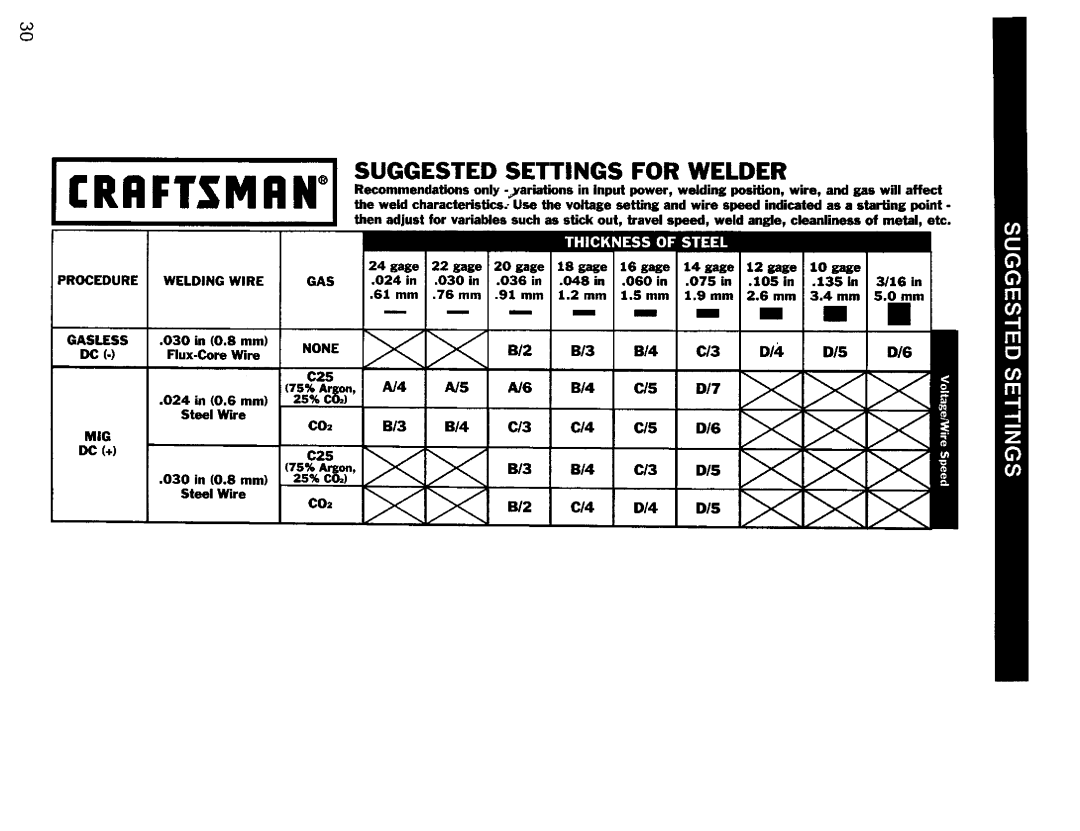

SUGGESTED SETTINGS FOR WELDER

I CRRFTSMRN°I Recommendations only

the weld characteristics: Use the voltage setting and wire speed indicated as a starting point - then adjust for var!_M,_ such as stick out, travel

PROCEDURE WELDING WIRE

GASLESS .030 in (0.8 mm)

OC

.024 in (0.6 mm)

Steel Wire

MIG

DC (+)

.030 in (0.8 mm) Steel Wire

w:l[_:q:t-_-l,]s. 11 _=_

| 24 gage | 22 gage | 20 pge | 16 gage | 16 gage | 14 gage | 12 gage | 10 gage |

| |

GAS | .024 in | .030 in | .036 in | .048 in | .060 in | .075 in | .105 | in | .135 in | 3/1G in |

| .61mm | .76ram | .91ram | 1.2ram | 1.Smm | 1.9mm | 2.6 | men | 3.4mm | 5.0mm |

| mm | m | m |

|

|

|

| |||

NONE | .I/_ | jf_, | B/2 | B/3 | B/4 | C/3 | D/4 | DIS | D/6 | |

|

|

|

|

|

| |||||

C25 |

|

|

|

|

|

|

|

|

| |

(7s% | Argon, | A/4 | A/5 | AJ6 | B/4 | C/5 |

|

|

|

|

25% | CO:) |

|

|

|

|

|

|

|

|

|

C02 | B/3 | B/4 | C/3 | C/4 | C/5 |

|

|

|

| |

(7s% Argo., | B/3 | B/4 | C/3 |

25% CO=) |

|

|

|

C02 |

|

|

|