NOTE: WHEN USING

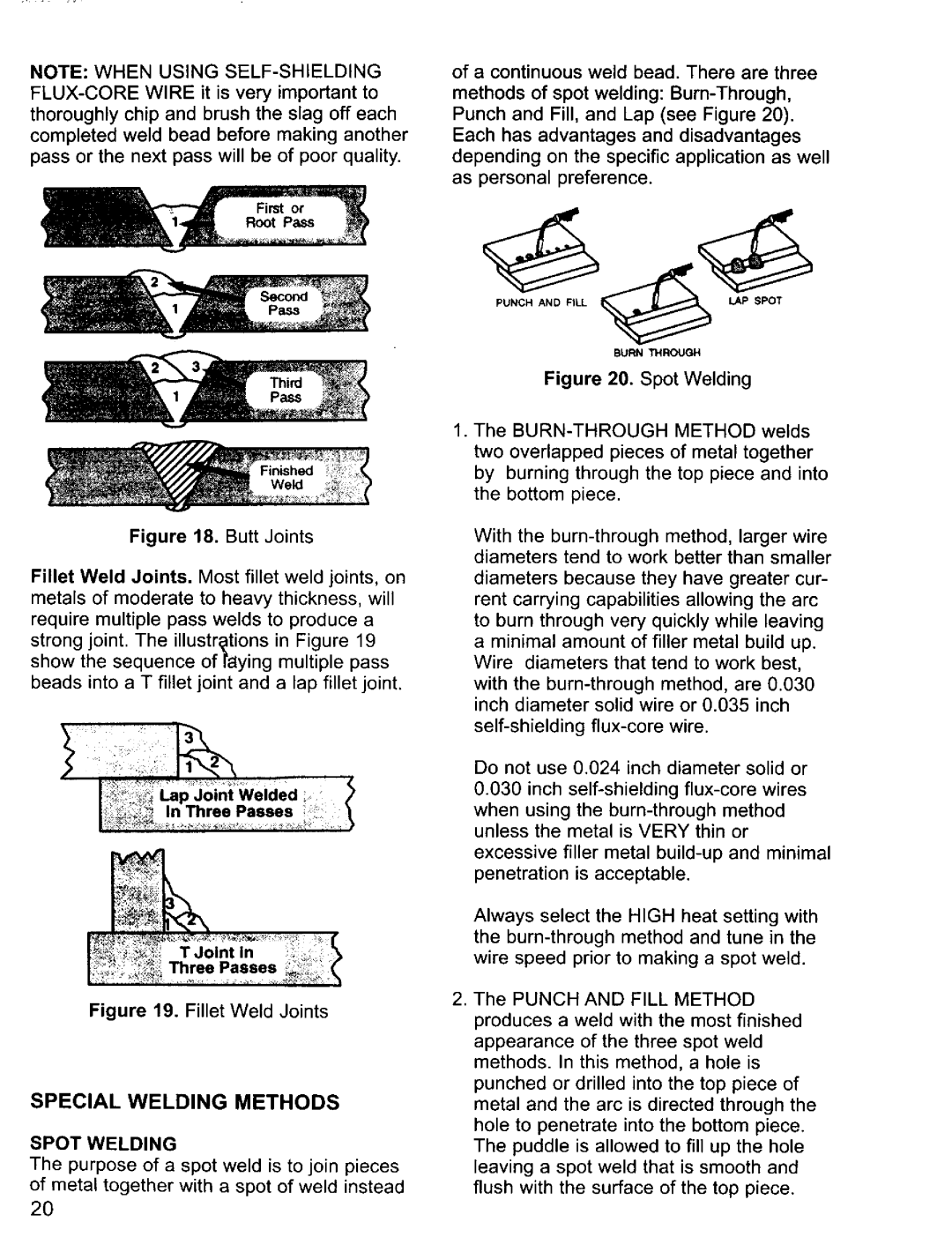

of a continuous weld bead. There are three methods of spot welding:

Figure 18. Butt Joints

Fillet Weld Joints. Most fillet weld joints, on metals of moderate to heavy thickness, will require multiple pass welds to produce a

strong joint. The illustrations in Figure 19 show the sequence of laying multiple pass beads into a T fillet joint and a lap fillet joint.

i

Lap Joint Welded

I _ In Three Passes

_ __ TJont n

li_,_ _ Three Passes (

Figure 19. Fillet Weld Joints

SPECIAL WELDING METHODS

SPOT WELDING

The purpose of a spot weld is to join pieces of metal together with a spot of weld instead 20

PUNCH AND FILL _ | LAP SPOT |

BURN THROUGH