degrees. The point at which the gun handle is parallel to the work piece. If angle A is increased, penetration will increase. If angle A is decreased, pene- tration will decrease also.

mii

Angle A

Figure 9. Gun Position, Angle A

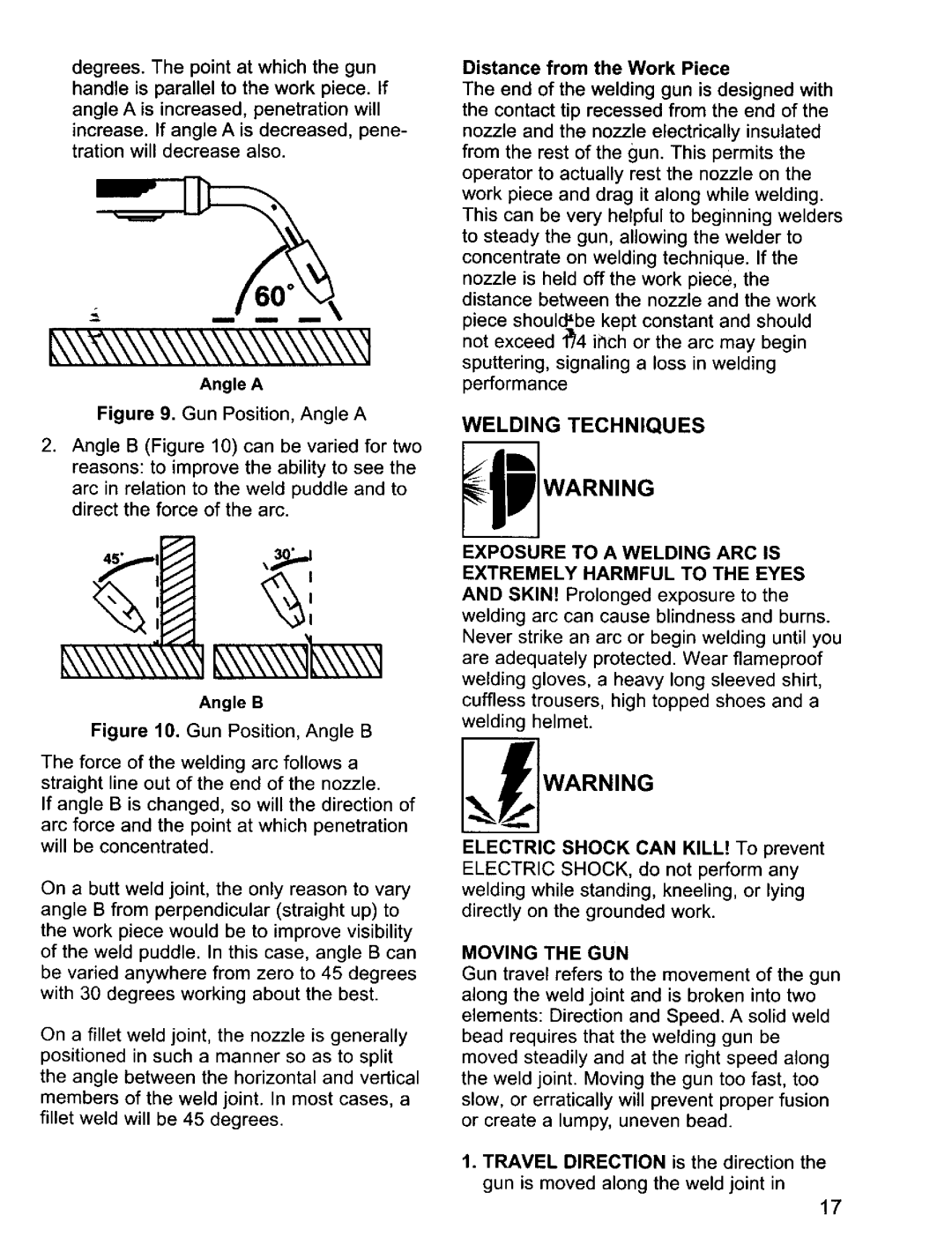

. Angle B (Figure 10) can be varied for two reasons: to improve the ability to see the arc in relation to the weld puddle and to direct the force of the arc.

Angle B

Figure 10. Gun Position, Angle B

The force of the welding arc follows a straight line out of the end of the nozzle.

If angle B is changed, so will the direction of arc force and the point at which penetration will be concentrated.

On a butt weld joint, the only reason to vary angle B from perpendicular (straight up) to the work piece would be to improve visibility of the weld puddle. In this case, angle B can be varied anywhere from zero to 45 degrees with 30 degrees working about the best.

On a fillet weld joint, the nozzle is generally positioned in such a manner so as to split the angle between the horizontal and vertical members of the weld joint. In most cases, a fillet weld will be 45 degrees.

Distance from the Work Piece

The end of the welding gun is designed with the contact tip recessed from the end of the nozzle and the nozzle electrically insulated from the rest of the gun. This permits the operator to actually rest the nozzle on the work piece and drag it along while welding. This can be very helpful to beginning welders to steady the gun, allowing the welder to concentrate on welding technique. If the nozzle is held off the work piece, the distance between the nozzle and the work piece shoul_be kept constant and should not exceed 1_4 inch or the arc may begin sputtering, signaling a loss in welding performance

WELDING TECHNIQUES

WARNING

EXPOSURE TO A WELDING ARC IS EXTREMELY HARMFUL TO THE EYES AND SKIN! Prolonged exposure to the welding arc can cause blindness and burns. Never strike an arc or begin welding until you are adequately protected. Wear flameproof welding gloves, a heavy long sleeved shirt, cuffless trousers, high topped shoes and a welding helmet.

ELECTRIC SHOCK CAN KILL! To prevent ELECTRIC SHOCK, do not perform any

welding while standing, kneeling, or lying directly on the grounded work.

MOVING THE GUN

Gun travel refers to the movement of the gun along the weld joint and is broken into two elements: Direction and Speed. A solid weld bead requires that the welding gun be moved steadily and at the right speed along the weld joint. Moving the gun too fast, too slow, or erratically will prevent proper fusion or create a lumpy, uneven bead.

1.TRAVEL DIRECTION is the direction the gun is moved along the weld joint in

17