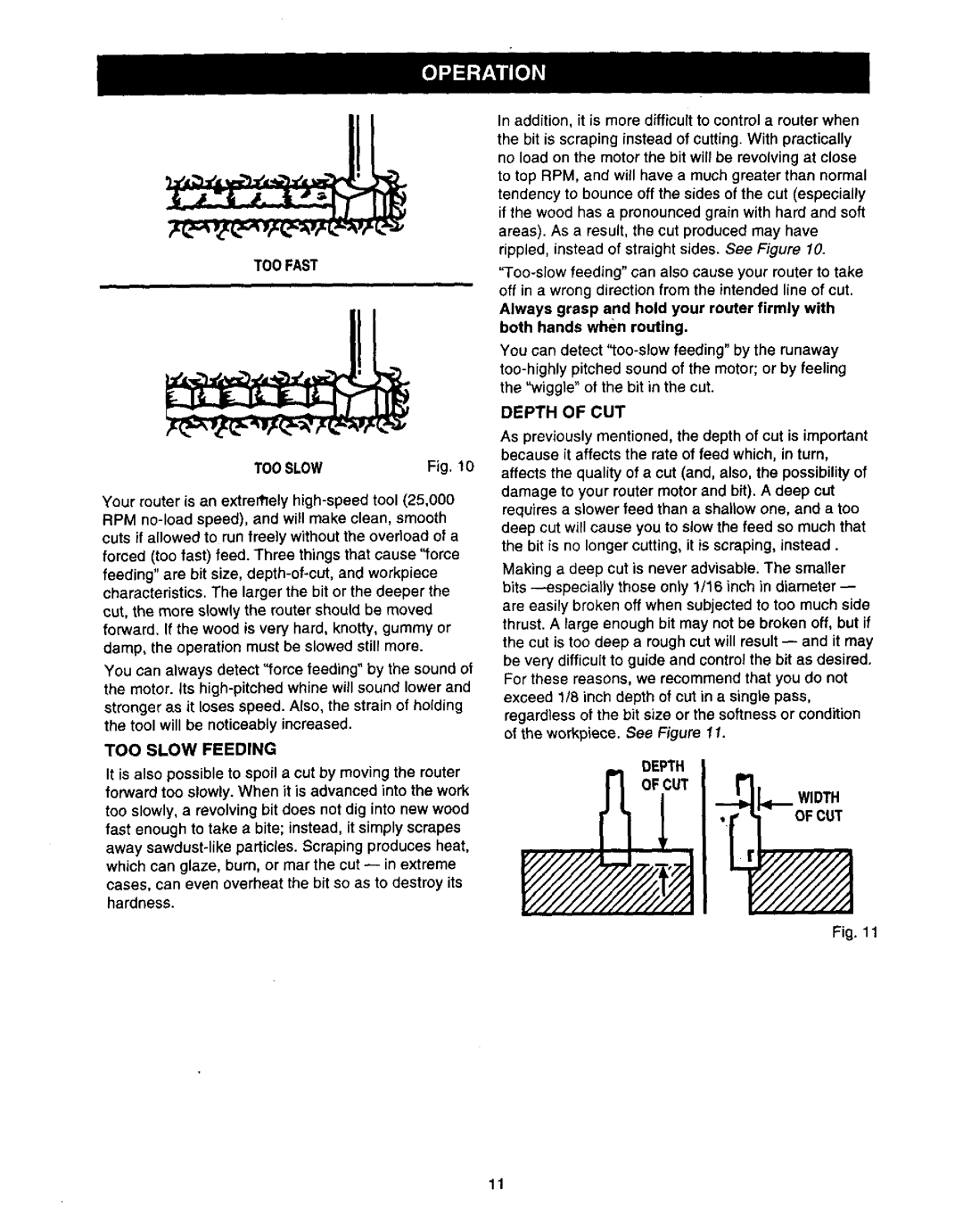

TOO FAST

TO0 SLOW | Fig. 10 |

Your router is an extremely

You can always detect "force feeding" by the sound of the motor. Its

TOO SLOW FEEDING

It is also possible to spoil a cut by moving the router forward too slowly. When it is advanced into the work too slowly, a revolving bit does not dig into new wood fast enough to take a bite; instead, it simply scrapes away

In addition, it is more difficult to control a router when the bit is scraping instead of cutting. With practically no load on the motor the bit will be revolving at close to top RPM, and will have a much greater than normal tendency to bounce off the sides of the cut (especially if the wood has a pronounced grain with hard and soft areas). As a result, the cut produced may have rippled, instead of straight sides. See Figure 10.

Always grasp and hold your router firmly with both hands when routing.

You can detect

DEPTH OF CUT

As previously mentioned, the depth of cut is important because it affects the rate of feed which, in turn, affects the quality of a cut (and, also, the possibility of damage to your router motor and bit). A deep cut requires a slower feed than a shallow one, and a too deep cut will cause you to slow the feed so much that the bit is no longer cutting, it is scraping, instead.

Making a deep cut is never advisable. The smaller bits

For these reasons, we recommend that you do not exceed 1/8 inch depth of cut in a single pass, regardless of the bit size or the softness or condition of the workpiece. See Figure 11.

WIDTH

OF CUT

Fig. 11

11