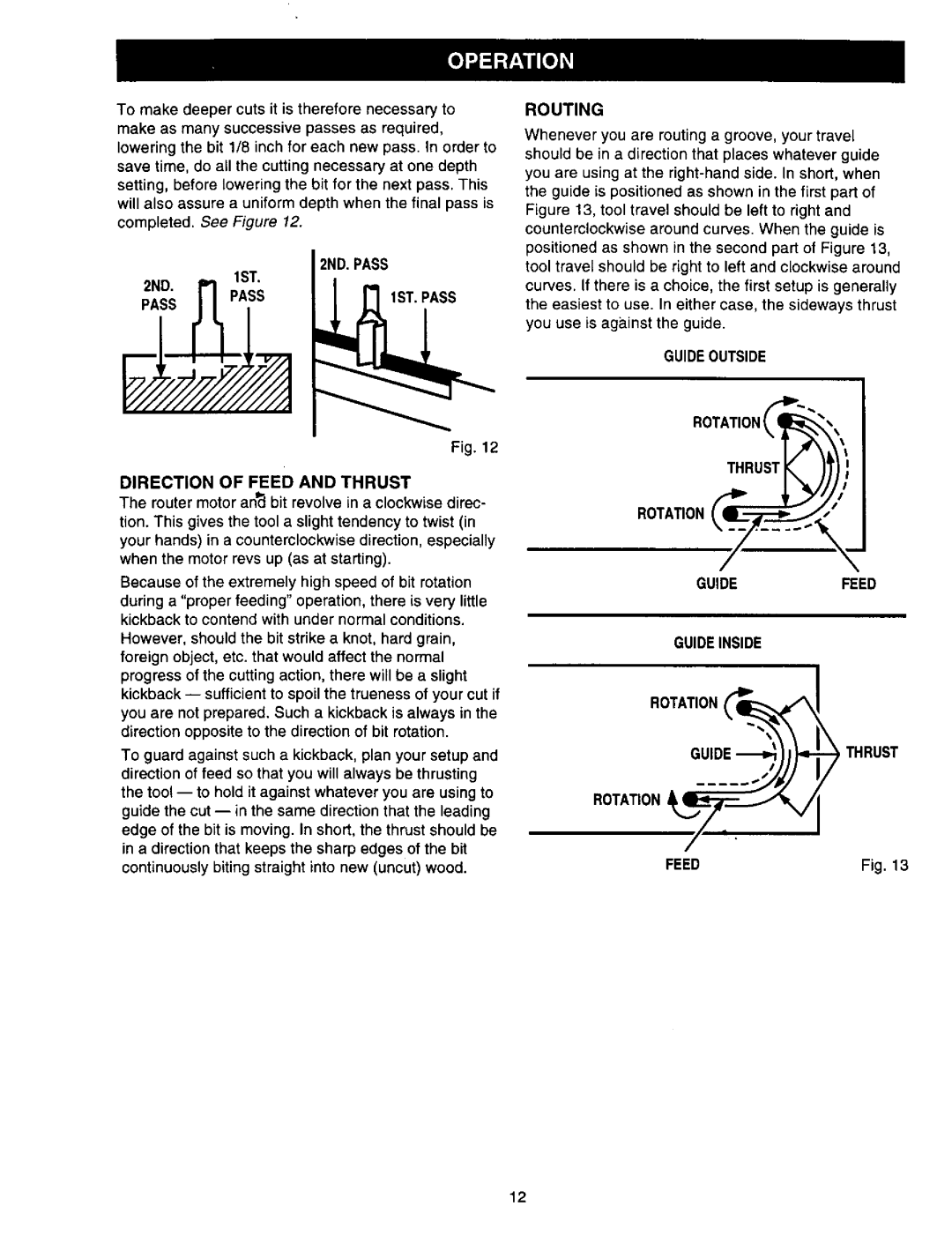

To makedeepercutsit isthereforenecessaryto makeasmanysuccessivepassesasrequired, loweringthebit1/8inchforeachnewpass.Inorderto savetime,doallthecuttingnecessaryatonedepth setting,beforeloweringthebitforthenextpass.This willalsoassureauniformdepthwhenthefinalpassis

completedSee. Figure 12.

ROUTING

Whenever you are routing a groove, your travel should be in a direction that places whatever guide you are using at the

2ND.

2ND. PASS

1ST.

tool travel should be right to left and clockwise around curves. If there is a choice, the first setup is generally

PASS

PASS

the easiest to use. In either case, the sideways thrust you use is ag.ainst the guide.

GUIDEOUTSIDE

Fig. 12

DIRECTION OF FEED AND THRUST

The router motor an_ bit revolve in a clockwise direc- tion. This gives the tool a slight tendency to twist (in your hands) in a counterclockwise direction, especially when the motor revs up (as at starting).

Because of the extremely high speed of bit rotation during a "proper feeding" operation, there is very little kickback to contend with under normal conditions. However, should the bit strike a knot, hard grain, foreign object, etc. that would affect the normal progress of the cutting action, there will be a slight kickback

To guard against such a kickback, plan your setup and direction of feed so that you will always be thrusting the tool

ROTATION\

t

I

I

I

t

ROTATION__..___,

/

GUIDEFEED

GUIDEINSIDE

ROTATION_1_

THRUST

FEED | Fig. 13 |

12