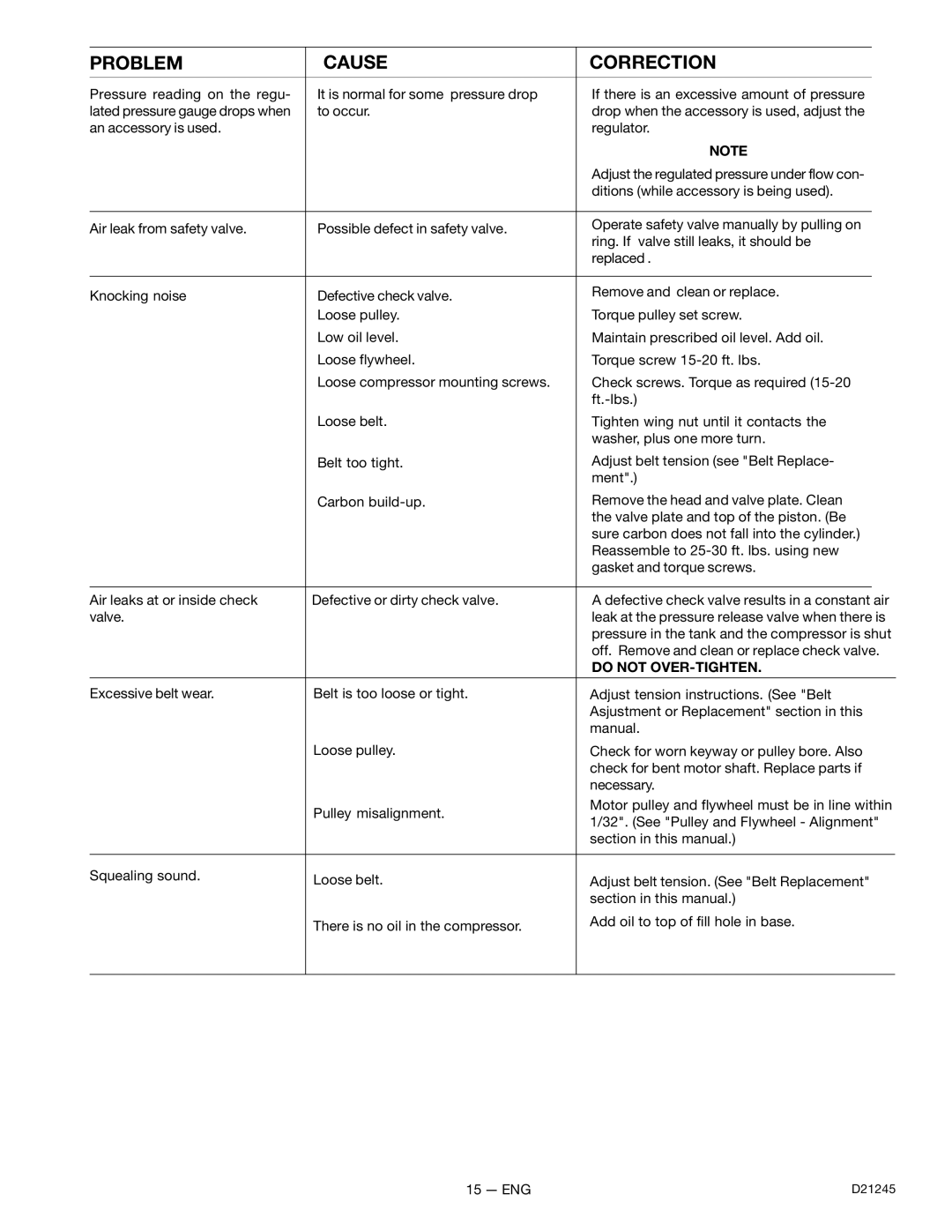

PROBLEM | CAUSE | CORRECTION |

| |

|

|

|

| |

Pressure reading on the regu- | It is normal for some pressure drop | If there is an excessive amount of pressure | ||

lated pressure gauge drops when | to occur. | drop when the accessory is used, adjust the | ||

an accessory is used. |

| regulator. | ||

|

| NOTE | ||

|

| Adjust the regulated pressure under flow con- | ||

|

| ditions (while accessory is being used). | ||

|

|

|

| |

Air leak from safety valve. | Possible defect in safety valve. | Operate safety valve manually by pulling on | ||

ring. If valve still leaks, it should be | ||||

|

| |||

|

| replaced . | ||

|

|

|

| |

Knocking noise | Defective check valve. | Remove and clean or replace. | ||

|

| |||

| Loose pulley. | Torque pulley set screw. | ||

| Low oil level. | Maintain prescribed oil level. Add oil. | ||

| Loose flywheel. | Torque screw | ||

| Loose compressor mounting screws. | Check screws. Torque as required | ||

|

| |||

| Loose belt. | Tighten wing nut until it contacts the | ||

|

| washer, plus one more turn. | ||

| Belt too tight. | Adjust belt tension (see "Belt Replace- | ||

|

| ment".) | ||

| Carbon | Remove the head and valve plate. Clean | ||

|

| the valve plate and top of the piston. (Be | ||

|

| sure carbon does not fall into the cylinder.) | ||

|

| Reassemble to | ||

|

| gasket and torque screws. | ||

|

|

|

| |

Air leaks at or inside check | Defective or dirty check valve. | A defective check valve results in a constant air | ||

valve. |

| leak at the pressure release valve when there is | ||

|

| pressure in the tank and the compressor is shut | ||

|

| off. Remove and clean or replace check valve. | ||

|

| DO NOT | ||

|

|

| ||

Excessive belt wear. | Belt is too loose or tight. | Adjust tension instructions. (See "Belt | ||

|

| Asjustment or Replacement" section in this | ||

|

| manual. | ||

| Loose pulley. | Check for worn keyway or pulley bore. Also | ||

|

| check for bent motor shaft. Replace parts if | ||

|

| necessary. | ||

| Pulley misalignment. | Motor pulley and flywheel must be in line within | ||

| 1/32". (See "Pulley and Flywheel - Alignment" | |||

|

| |||

|

| section in this manual.) | ||

|

|

|

| |

Squealing sound. | Loose belt. | Adjust belt tension. (See "Belt Replacement" | ||

| ||||

|

| section in this manual.) | ||

| There is no oil in the compressor. | Add oil to top of fill hole in base. | ||

|

|

| ||

|

|

|

| |

15 — ENG | D21245 |