MAINTENANCE

__To avoid personal injury, always shut off and unplug the compressor and relieve all air pressure from the system before performing any service on the air

compressor.

Regular maintenance will ensure

DRAINING THE TANK

,__Condensationwill accumulate in

the tank. To prevent corrosion of the tank from the inside, this moisture must be drained at the end of every workday. Be sure to wear protective eyewear. Relieve the air pressure in the system and open the petcock on the bottom of the tank to drain.

CHECKING THE OIL

To check the oil level in the pump, unscrew the dipstick and wipe off oil. Screw the dipstick all the way in and then unscrew. The pump oil level should be between between add (see C) and full (see B). Replace the dipstick. Do not overfill or underfill.

ADJUSTING DRIVE BELT TENSION

__RISK OF INJURY. This unit starts

automatically. ALWAYS shut off the compressor, remove the plug from the outlet, and bleed all pressure from the system before servicing the compressor, and when the compressor is not in use. Do not use the unit with the shrouds or belt guard removed. Serious injury could occur from contact with moving parts.

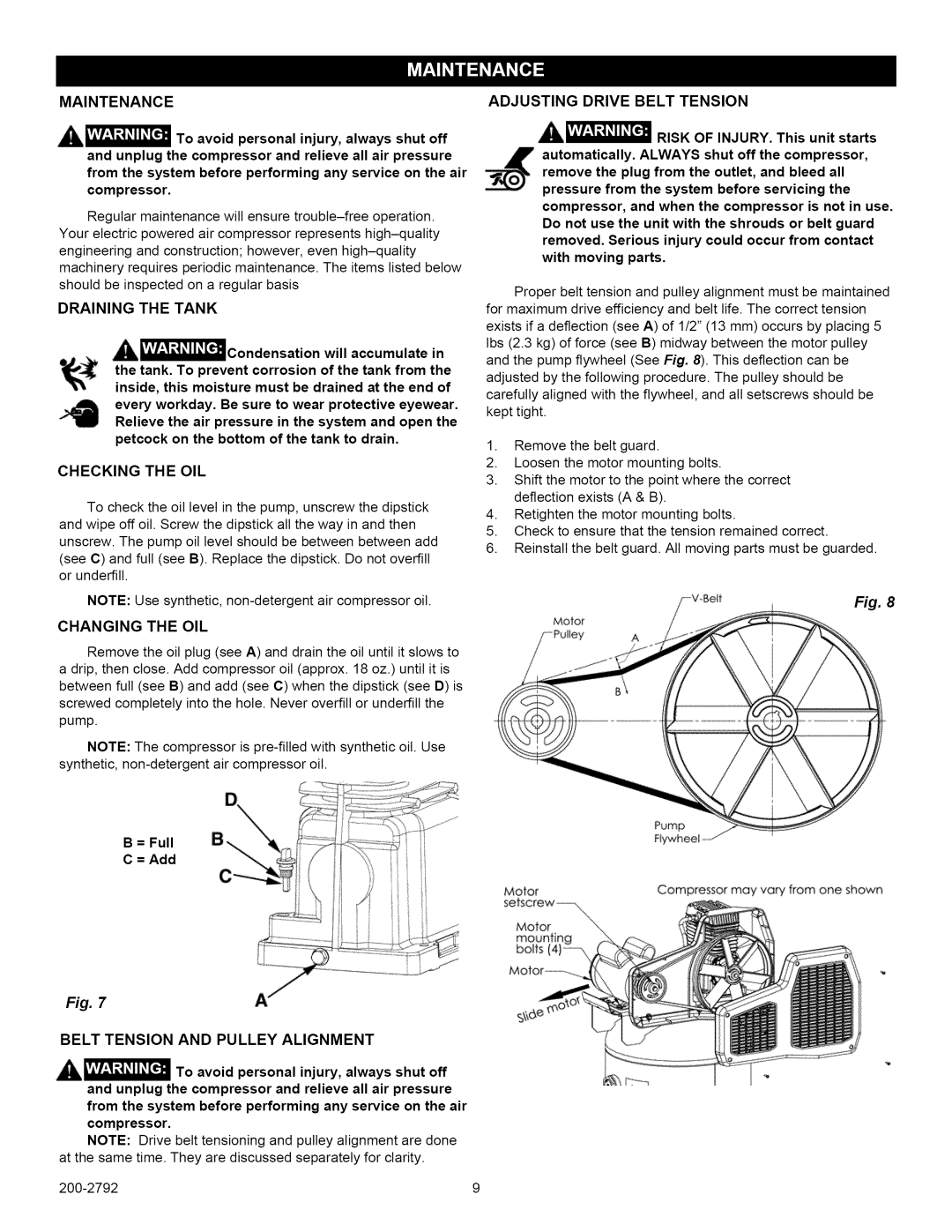

Proper belt tension and pulley alignment must be maintained for maximum drive efficiency and belt life. The correct tension exists if a deflection (see A) of 112" (13 mm) occurs by placing 5 lbs (2.3 kg) of force (see B) midway between the motor pulley and the pump flywheel (See Fig. 8). This deflection can be adjusted by the following procedure. The pulley should be carefully aligned with the flywheel, and all setscrews should be kept tight.

1.Remove the belt guard.

2.Loosen the motor mounting bolts.

3.Shift the motor to the point where the correct deflection exists (A & B).

4.Retighten the motor mounting bolts.

5.Check to ensure that the tension remained correct.

6.Reinstall the belt guard. All moving parts must be guarded.

NOTE: Use synthetic, | Fig. 8 | |

CHANGING | THE OIL | Motor |

| ||

Remove the oil plug (see A) and drain the oil until it slows to |

| |

a drip, then close. Add compressor oil (approx. 18 oz.) until it is |

| |

between full (see B) and add (see C) when the dipstick (see D) is |

| |

screwed completely into the hole. Never overfill or underfill the |

| |

pump. |

|

|

NOTE: The compressor is |

| |

synthetic, |

| |

|

| Pump |

B = Full | F_ywhee_ | |

C = Add |

| |

| Motor | Compressor may vory from one shown |

| Motor |

|

| bolls |

|

Fig. 7 | A |

|

BELT TENSION AND PULLEY ALIGNMENT

__To avoid personal injury, always shut off and unplug the compressor and relieve all air pressure from the system before performing any service on the air

compressor.

NOTE: Drive belt tensioning and pulley alignment are done at the same time. They are discussed separately for clarity.

9 |