Straight Edge Shaping | Across The Grain | |

|

|

|

|

|

|

After installing the cutter but before plugging in, (be sure to check for proper rotation) position the fence faces parallel to each other and lock them in place. Rotate the cutter until one of the cutting face’s is 90 degrees from the fence faces. Place the workpiece against the infeed fence and slide it against the face of the cutter to get an idea of the cut profile. Now adjust the Spindle height and the Fence location to give the approximate cut profile. A drawn outline of the desired cut profile on the end of the workpiece will help in making adjustments. Try out the setting on a piece of scrap and then make final adjustments.

If the entire face of the workpiece is to be shaped, make a test cut with scrap.

When about 2'' of the test piece is adjacent

Always install the keyed washer directly under the jam nut; otherwise, the nut may loosen and serious injury may result.

A

1.Cut the workpiece about 1⁄4'' oversize and trim after shaping.

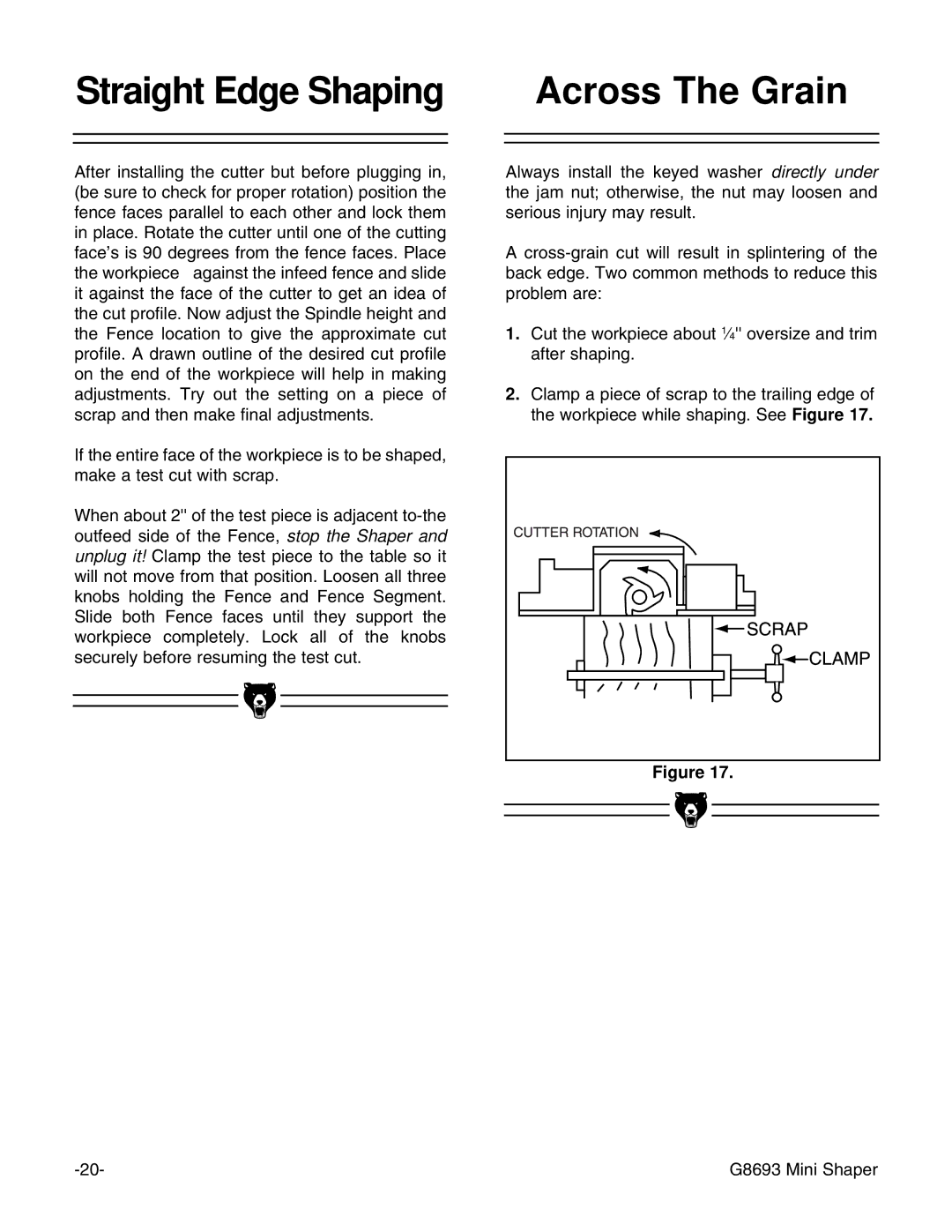

2.Clamp a piece of scrap to the trailing edge of the workpiece while shaping. See Figure 17.

Figure 17.

|

|

|

|

|

|

|

|

|

| G8693 Mini Shaper | |

|

|