Large Workpiece

When shaping long, wide or cumbersome work- pieces, the table may be too small to provide full support. An extension for the table can be added to the sides and front. Use only smooth, flat wood and be sure the extension is on the same level as the Mini Shaper table.

The Fence faces are drilled to allow the addition of fence extensions or wooden faces to provide more support.

Many good books on woodworking provide detailed instructions on shaper operation, pat- terns, fixtures and jigs.

Keep hands in the clear. Never jeopardize your hands; keep them at least six inches from the cut- ter at all times. If workpiece is small, use a hold- ing jig of some type to guide it past the cutter.

Ring Guard (REF 19) should be used and prop- erly adjusted when fence is removed.

Curved Workpiece

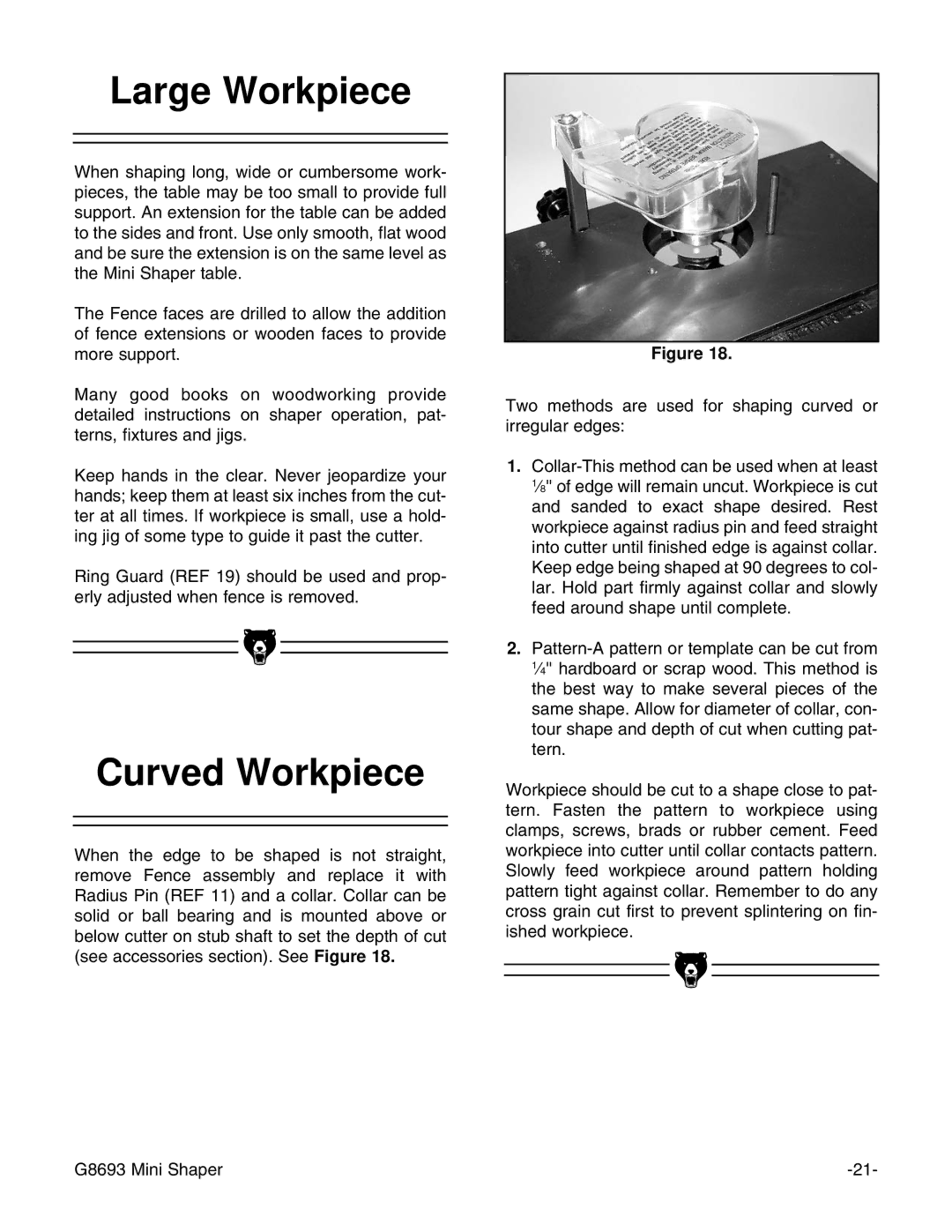

When the edge to be shaped is not straight, remove Fence assembly and replace it with Radius Pin (REF 11) and a collar. Collar can be solid or ball bearing and is mounted above or below cutter on stub shaft to set the depth of cut (see accessories section). See Figure 18.

Figure 18.

Two methods are used for shaping curved or irregular edges:

1.

2.

Workpiece should be cut to a shape close to pat- tern. Fasten the pattern to workpiece using clamps, screws, brads or rubber cement. Feed workpiece into cutter until collar contacts pattern. Slowly feed workpiece around pattern holding pattern tight against collar. Remember to do any cross grain cut first to prevent splintering on fin- ished workpiece.

G8693 Mini Shaper |