INSTALLATION (CONTINUED)

AIR PURGING

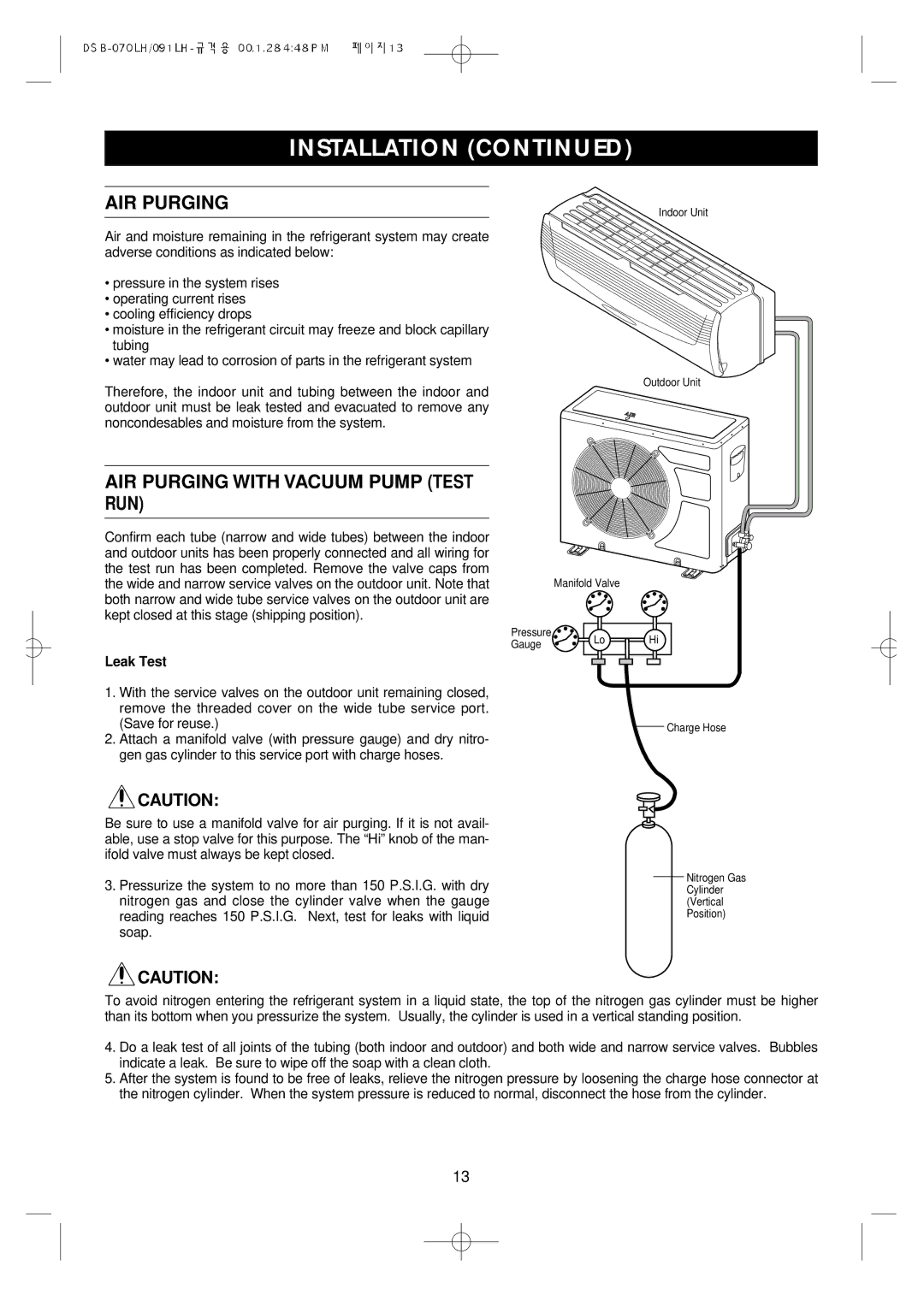

Indoor Unit

Air and moisture remaining in the refrigerant system may create adverse conditions as indicated below:

• pressure in the system rises

•operating current rises

•cooling efficiency drops

•moisture in the refrigerant circuit may freeze and block capillary tubing

•water may lead to corrosion of parts in the refrigerant system

Outdoor Unit

Therefore, the indoor unit and tubing between the indoor and outdoor unit must be leak tested and evacuated to remove any noncondesables and moisture from the system.

AIR PURGING WITH VACUUM PUMP (TEST RUN)

Confirm each tube (narrow and wide tubes) between the indoor and outdoor units has been properly connected and all wiring for the test run has been completed. Remove the valve caps from the wide and narrow service valves on the outdoor unit. Note that both narrow and wide tube service valves on the outdoor unit are kept closed at this stage (shipping position).

Leak Test

1.With the service valves on the outdoor unit remaining closed, remove the threaded cover on the wide tube service port. (Save for reuse.)

2.Attach a manifold valve (with pressure gauge) and dry nitro- gen gas cylinder to this service port with charge hoses.

| Manifold Valve |

| |

Pressure | Lo | Hi | |

Gauge | |||

|

|

Charge Hose

![]() CAUTION:

CAUTION:

Be sure to use a manifold valve for air purging. If it is not avail- able, use a stop valve for this purpose. The “Hi” knob of the man- ifold valve must always be kept closed.

3.Pressurize the system to no more than 150 P.S.I.G. with dry nitrogen gas and close the cylinder valve when the gauge reading reaches 150 P.S.I.G. Next, test for leaks with liquid soap.

![]() CAUTION:

CAUTION:

Nitrogen Gas Cylinder (Vertical Position)

To avoid nitrogen entering the refrigerant system in a liquid state, the top of the nitrogen gas cylinder must be higher than its bottom when you pressurize the system. Usually, the cylinder is used in a vertical standing position.

4.Do a leak test of all joints of the tubing (both indoor and outdoor) and both wide and narrow service valves. Bubbles indicate a leak. Be sure to wipe off the soap with a clean cloth.

5.After the system is found to be free of leaks, relieve the nitrogen pressure by loosening the charge hose connector at the nitrogen cylinder. When the system pressure is reduced to normal, disconnect the hose from the cylinder.

13