FASTENING MACHINE TO SUPPORTING SURFACE

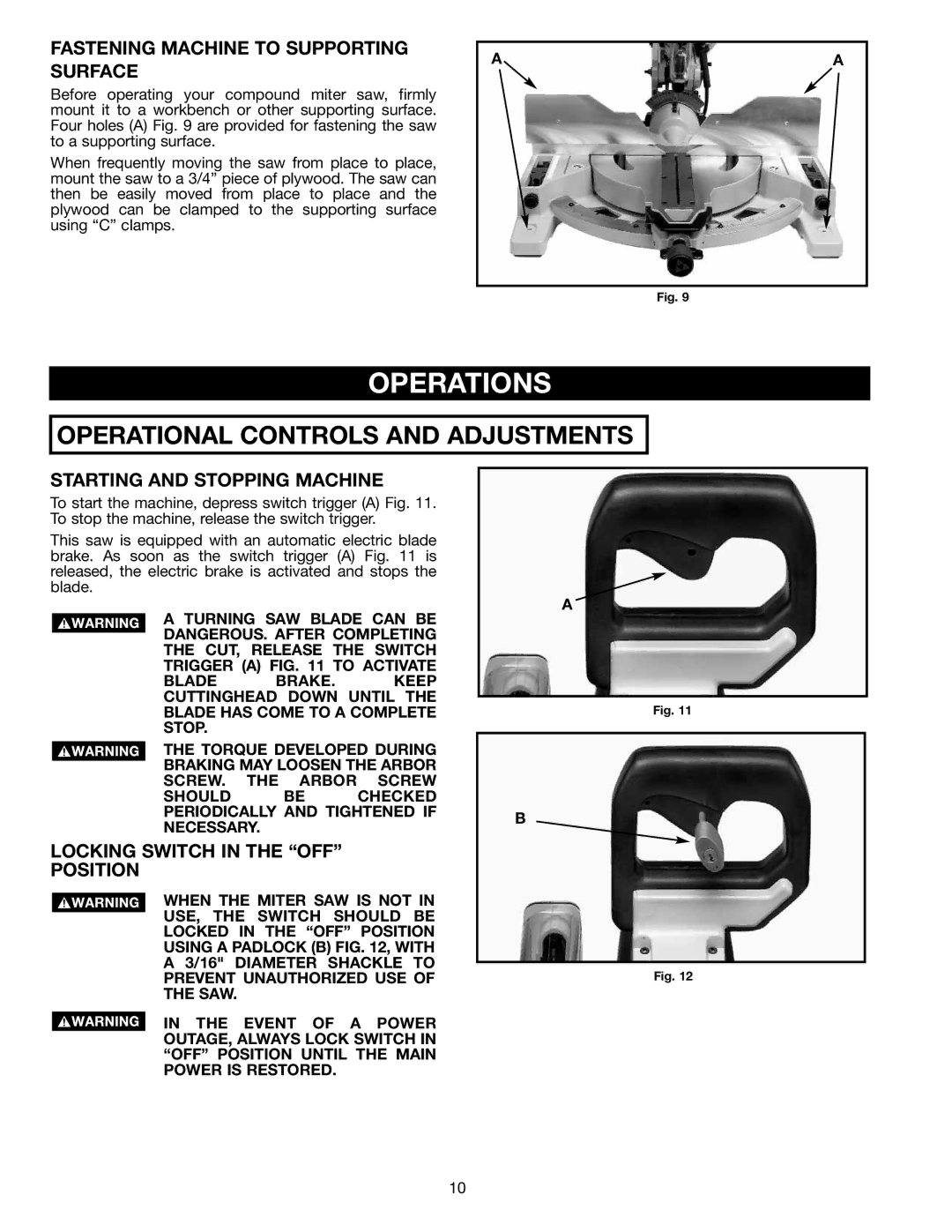

Before operating your compound miter saw, firmly mount it to a workbench or other supporting surface. Four holes (A) Fig. 9 are provided for fastening the saw to a supporting surface.

When frequently moving the saw from place to place, mount the saw to a 3/4” piece of plywood. The saw can then be easily moved from place to place and the plywood can be clamped to the supporting surface using “C” clamps.

AA

Fig. 9

OPERATIONS

OPERATIONAL CONTROLS AND ADJUSTMENTS

STARTING AND STOPPING MACHINE

To start the machine, depress switch trigger (A) Fig. 11. To stop the machine, release the switch trigger.

This saw is equipped with an automatic electric blade brake. As soon as the switch trigger (A) Fig. 11 is released, the electric brake is activated and stops the blade.

A TURNING SAW BLADE CAN BE

DANGEROUS. AFTER COMPLETING

THE CUT, RELEASE THE SWITCH

TRIGGER (A) FIG. 11 TO ACTIVATE

BLADE BRAKE. KEEP

CUTTINGHEAD DOWN UNTIL THE

BLADE HAS COME TO A COMPLETE

STOP.

THE TORQUE DEVELOPED DURING

BRAKING MAY LOOSEN THE ARBOR

SCREW. THE ARBOR SCREW

SHOULD BE CHECKED

PERIODICALLY AND TIGHTENED IF

NECESSARY.

LOCKING SWITCH IN THE “OFF” POSITION

WHEN THE MITER SAW IS NOT IN

USE, THE SWITCH SHOULD BE

LOCKED IN THE “OFF” POSITION

USING A PADLOCK (B) FIG. 12, WITH

A 3/16" DIAMETER SHACKLE TO

PREVENT UNAUTHORIZED USE OF

THE SAW.

IN THE EVENT OF A POWER OUTAGE, ALWAYS LOCK SWITCH IN “OFF” POSITION UNTIL THE MAIN POWER IS RESTORED.

A

Fig. 11

B

Fig. 12

10