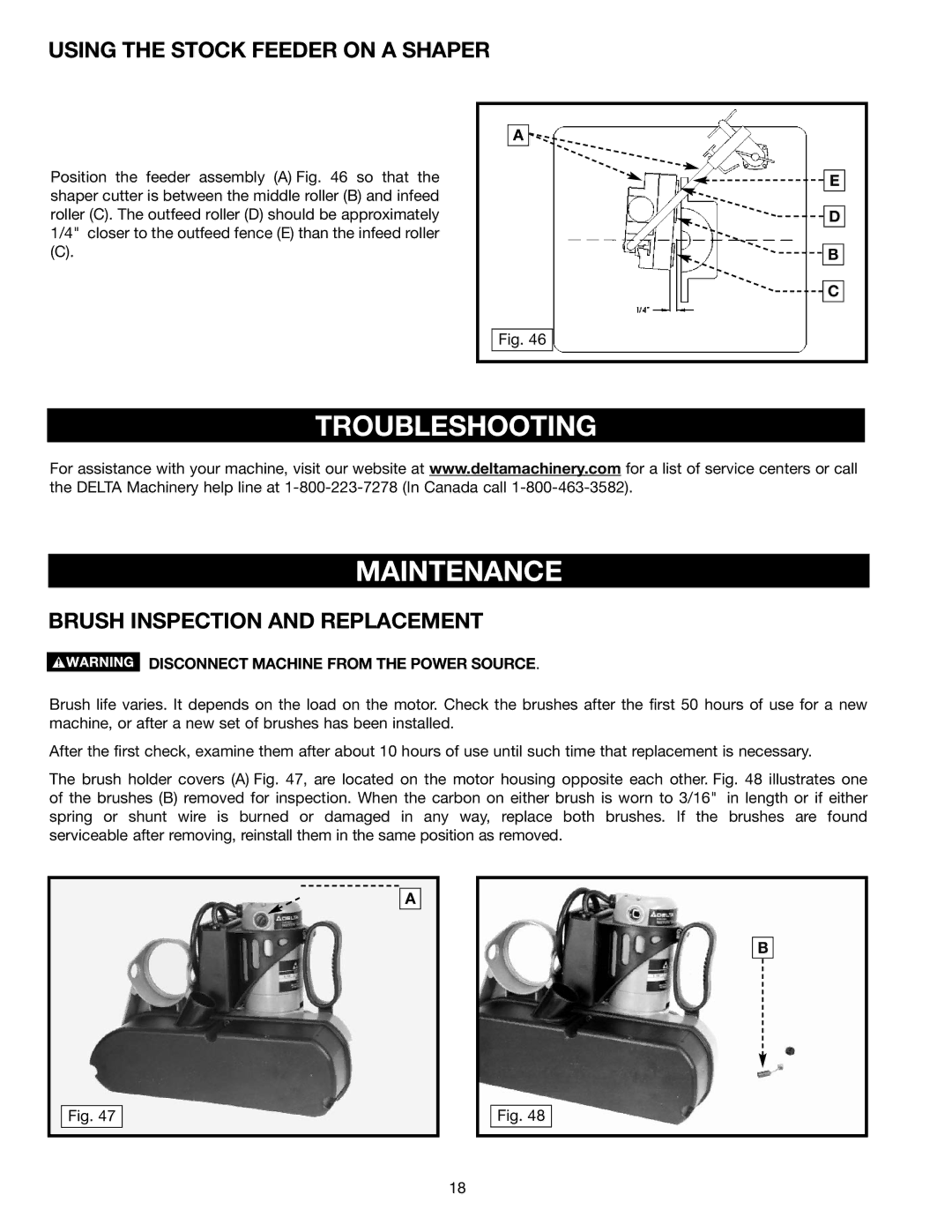

USING THE STOCK FEEDER ON A SHAPER

Position the feeder assembly (A) Fig. 46 so that the shaper cutter is between the middle roller (B) and infeed roller (C). The outfeed roller (D) should be approximately 1/4" closer to the outfeed fence (E) than the infeed roller

(C).

A ![]()

![]()

![]()

![]() E

E

![]()

![]()

![]() D

D

![]()

![]()

![]() B

B

![]()

![]() C

C

Fig. 46

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltamachinery.com for a list of service centers or call the DELTA Machinery help line at

MAINTENANCE

BRUSH INSPECTION AND REPLACEMENT

DISCONNECT MACHINE FROM THE POWER SOURCE.

Brush life varies. It depends on the load on the motor. Check the brushes after the first 50 hours of use for a new machine, or after a new set of brushes has been installed.

After the first check, examine them after about 10 hours of use until such time that replacement is necessary.

The brush holder covers (A) Fig. 47, are located on the motor housing opposite each other. Fig. 48 illustrates one of the brushes (B) removed for inspection. When the carbon on either brush is worn to 3/16" in length or if either spring or shunt wire is burned or damaged in any way, replace both brushes. If the brushes are found serviceable after removing, reinstall them in the same position as removed.

A

B

Fig. 47

Fig. 48

18