REPLACING FEED ROLLERS

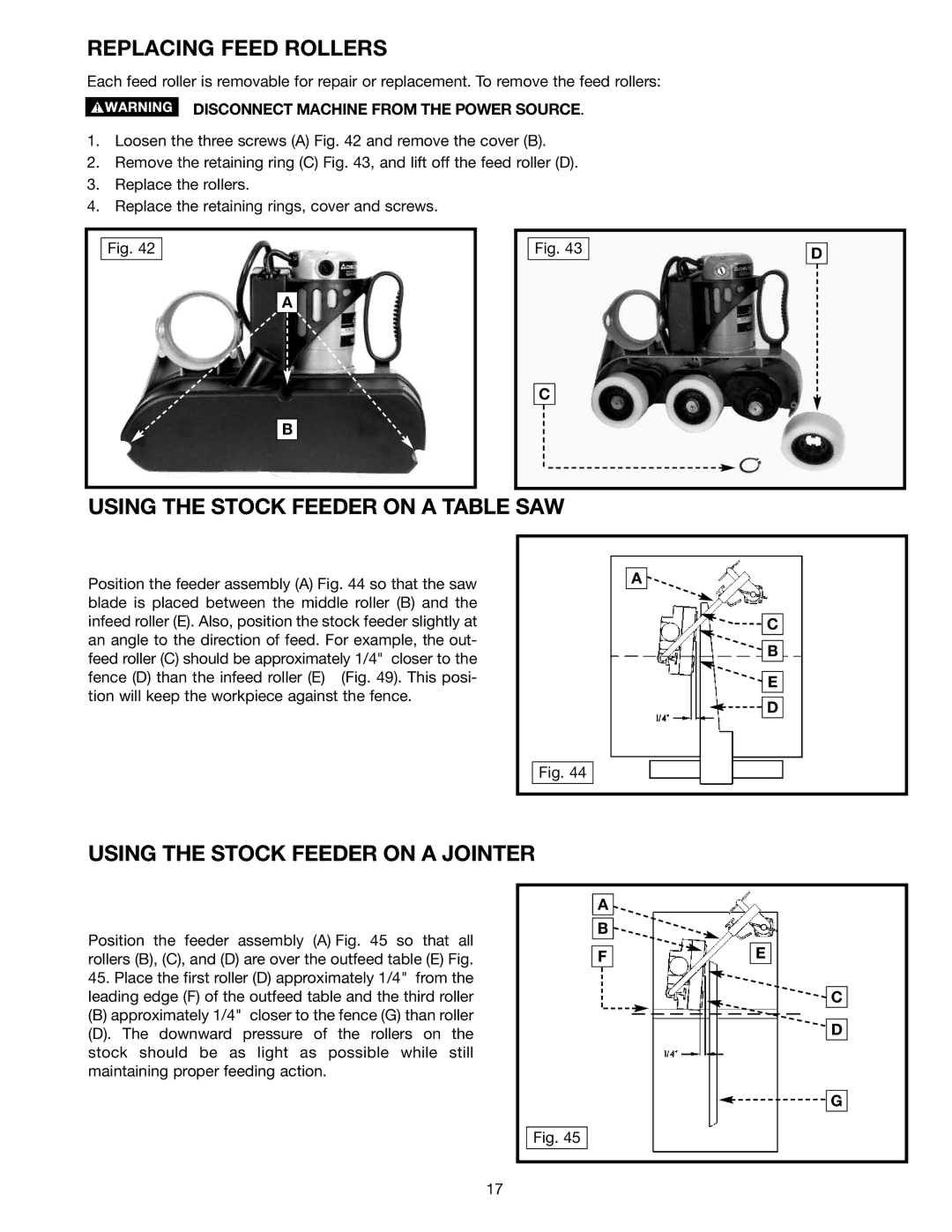

Each feed roller is removable for repair or replacement. To remove the feed rollers:

DISCONNECT MACHINE FROM THE POWER SOURCE.

1.Loosen the three screws (A) Fig. 42 and remove the cover (B).

2.Remove the retaining ring (C) Fig. 43, and lift off the feed roller (D).

3.Replace the rollers.

4.Replace the retaining rings, cover and screws.

Fig. 42 | Fig. 43 |

| A |

| C |

| B |

USING THE STOCK FEEDER ON A TABLE SAW

D

Position the feeder assembly (A) Fig. 44 so that the saw blade is placed between the middle roller (B) and the infeed roller (E). Also, position the stock feeder slightly at an angle to the direction of feed. For example, the out- feed roller (C) should be approximately 1/4" closer to the fence (D) than the infeed roller (E) (Fig. 49). This posi- tion will keep the workpiece against the fence.

A ![]()

![]()

![]()

![]() C

C

B

![]() E

E

![]()

![]()

![]() D

D

Fig. 44

USING THE STOCK FEEDER ON A JOINTER

Position the feeder assembly (A) Fig. 45 so that all rollers (B), (C), and (D) are over the outfeed table (E) Fig.

45.Place the first roller (D) approximately 1/4" from the leading edge (F) of the outfeed table and the third roller

(B) approximately 1/4" closer to the fence (G) than roller

(D). The downward pressure of the rollers on the stock should be as light as possible while still maintaining proper feeding action.

A |

|

B |

|

F | E |

| C |

| D |

| G |

Fig. 45 |

|

17