OPERATION

TO CALIBRATE THE 45° INWARD AND OUTWARD STOPS:

1.Loosen the beveling lock by rotating the handle counterclockwise.

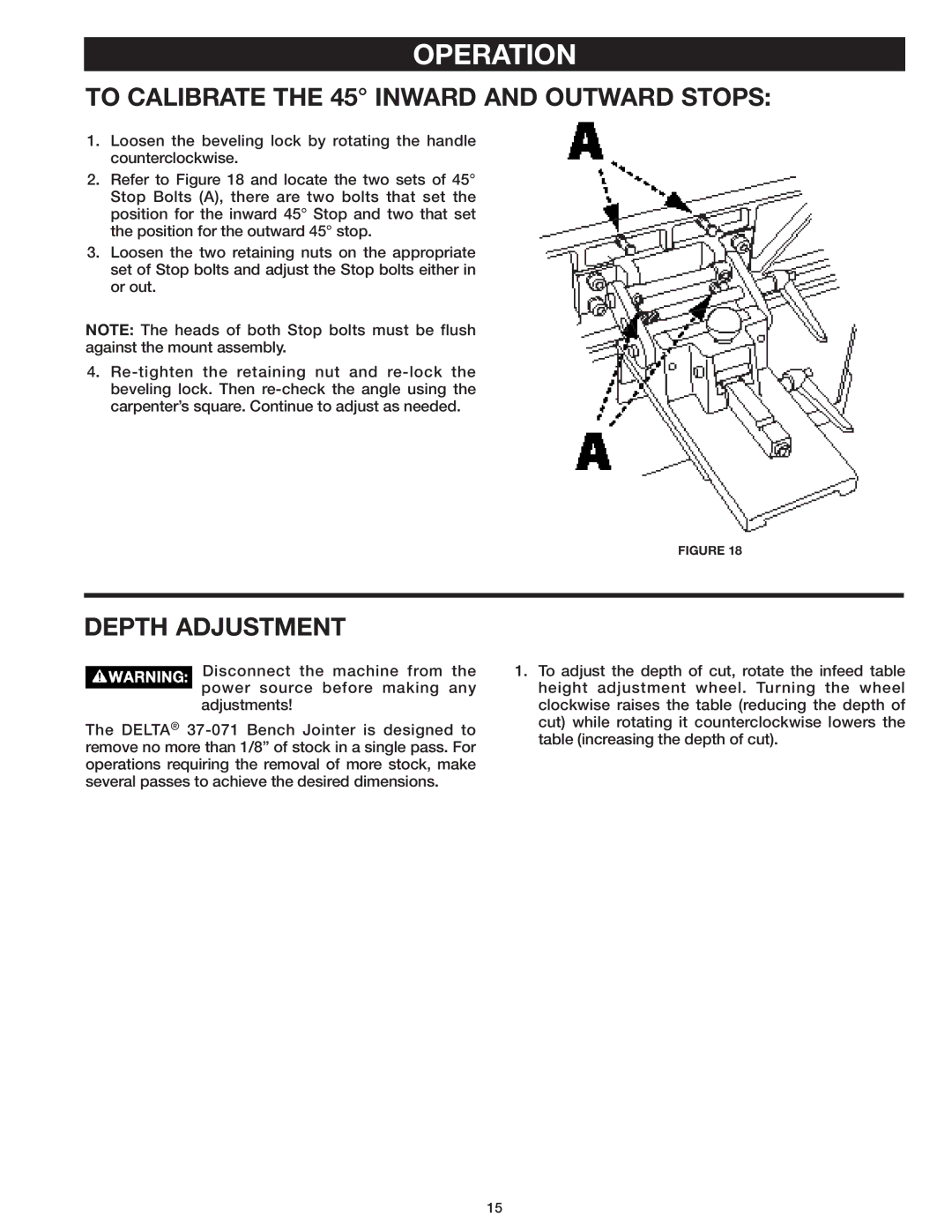

2.Refer to Figure 18 and locate the two sets of 45° Stop Bolts (A), there are two bolts that set the position for the inward 45° Stop and two that set the position for the outward 45° stop.

3.Loosen the two retaining nuts on the appropriate set of Stop bolts and adjust the Stop bolts either in or out.

NOTE: The heads of both Stop bolts must be flush against the mount assembly.

4.

FIGURE 18

DEPTH ADJUSTMENT

Disconnect the machine from the power source before making any adjustments!

The DELTA®

1.To adjust the depth of cut, rotate the infeed table height adjustment wheel. Turning the wheel clockwise raises the table (reducing the depth of cut) while rotating it counterclockwise lowers the table (increasing the depth of cut).

15