MAINTENANCE

CHANGING CUTTERHEAD KNIVES

Disconnect the machine from the power source before making any

adjustments!

Jointer knives are dangerously sharp. Use extreme caution when inspecting, removing, sharpening, or replacing knives into the

cutterhead. Failure to comply may cause serious injury.

The DELTA®

1.Place a scrap piece of wood between the spring- loaded cutter guard and fence in order to fully expose the cutterhead.

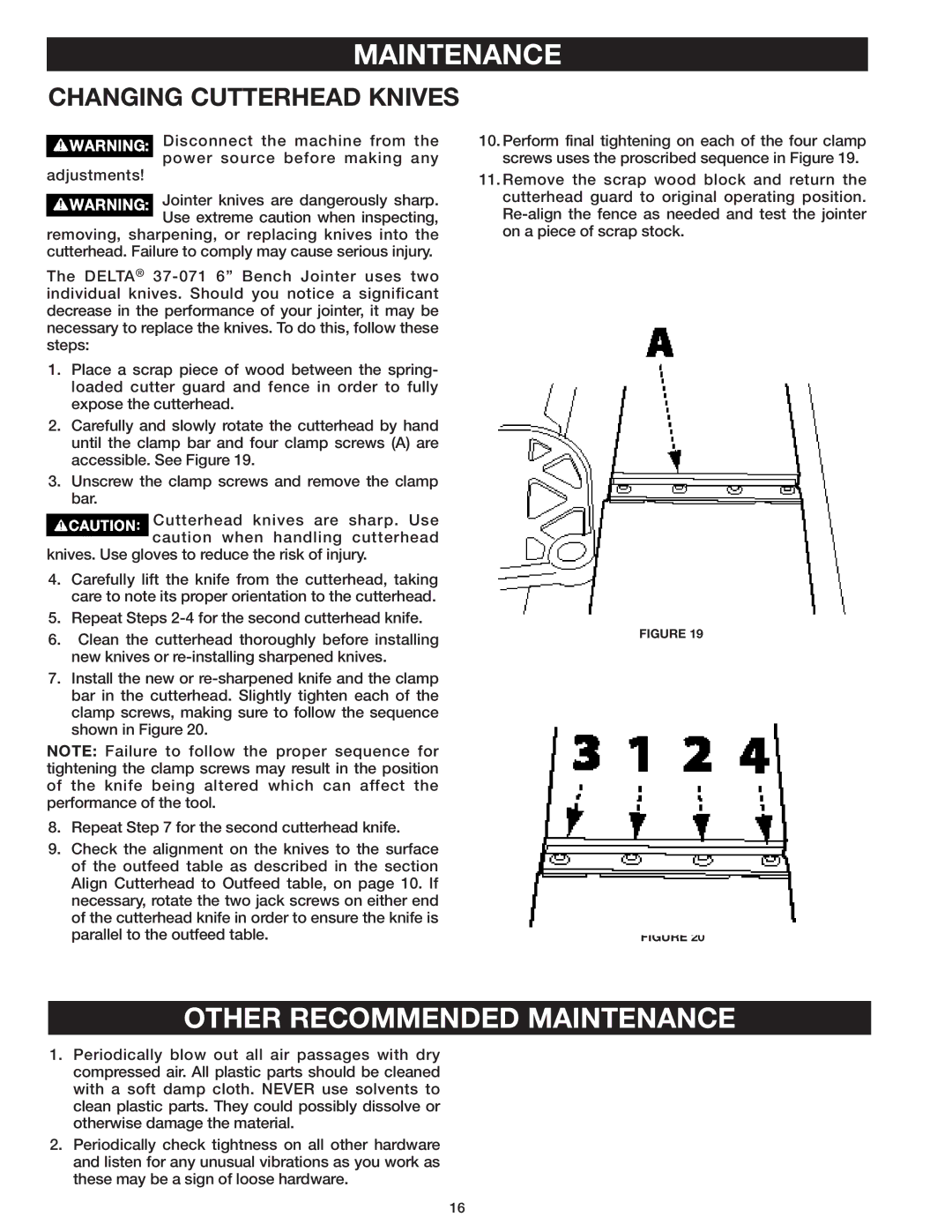

2.Carefully and slowly rotate the cutterhead by hand until the clamp bar and four clamp screws (A) are accessible. See Figure 19.

3.Unscrew the clamp screws and remove the clamp bar.

Cutterhead knives are sharp. Use caution when handling cutterhead

knives. Use gloves to reduce the risk of injury.

4.Carefully lift the knife from the cutterhead, taking care to note its proper orientation to the cutterhead.

5.Repeat Steps

6.Clean the cutterhead thoroughly before installing new knives or

7.Install the new or

NOTE: Failure to follow the proper sequence for tightening the clamp screws may result in the position of the knife being altered which can affect the performance of the tool.

8.Repeat Step 7 for the second cutterhead knife.

9.Check the alignment on the knives to the surface of the outfeed table as described in the section Align Cutterhead to Outfeed table, on page 10. If necessary, rotate the two jack screws on either end of the cutterhead knife in order to ensure the knife is parallel to the outfeed table.

10.Perform final tightening on each of the four clamp screws uses the proscribed sequence in Figure 19.

11.Remove the scrap wood block and return the cutterhead guard to original operating position.

FIGURE 19

FIGURE 20

OTHER RECOMMENDED MAINTENANCE

1.Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

2.Periodically check tightness on all other hardware and listen for any unusual vibrations as you work as these may be a sign of loose hardware.

16