GENERAL CUTTING OPERATIONS

Your machine can cut:

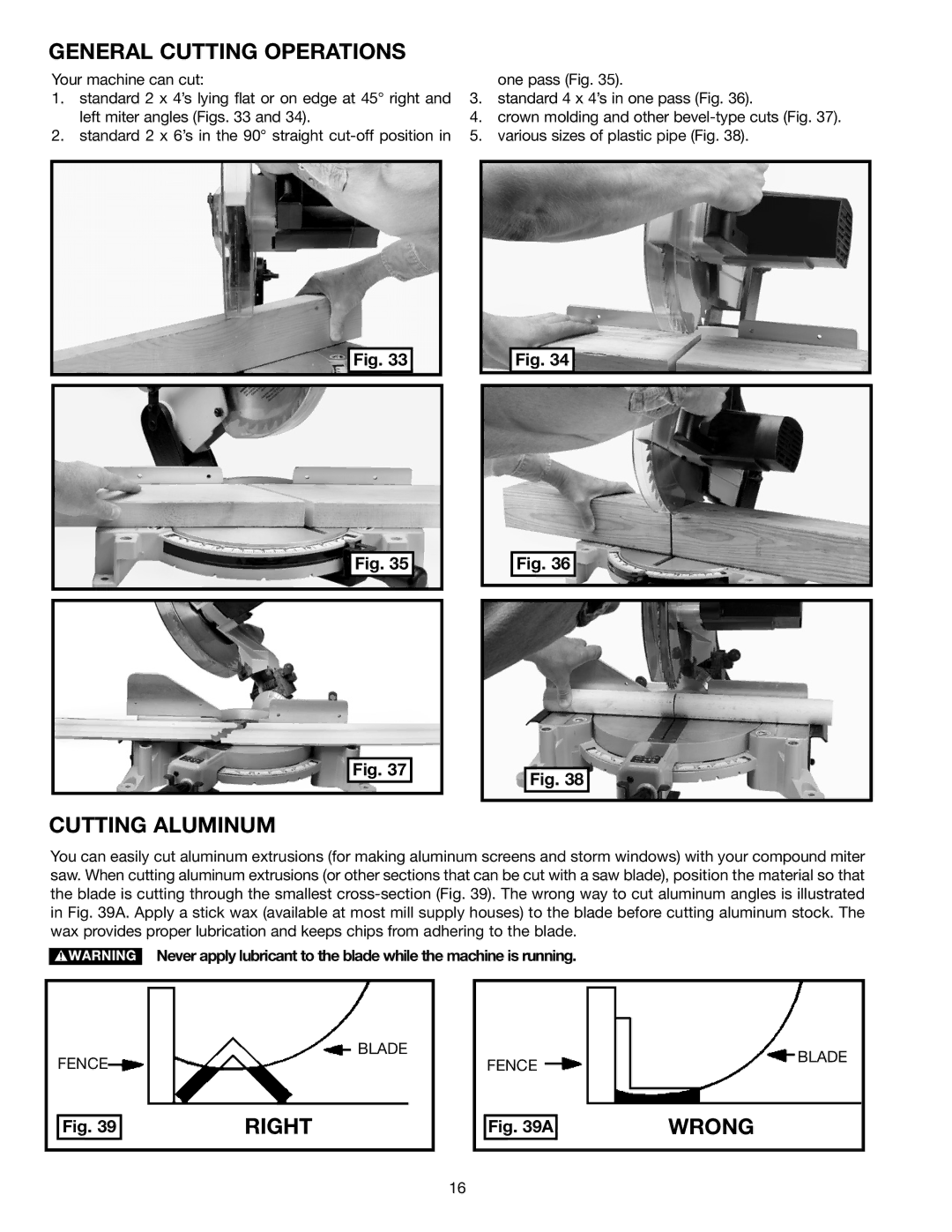

1.standard 2 x 4’s lying flat or on edge at 45° right and left miter angles (Figs. 33 and 34).

2.standard 2 x 6’s in the 90° straight

Fig. 33

Fig. 35

Fig. 37

one pass (Fig. 35).

3.standard 4 x 4’s in one pass (Fig. 36).

4.crown molding and other

5.various sizes of plastic pipe (Fig. 38).

Fig. 34

Fig. 36

Fig. 38

CUTTING ALUMINUM

You can easily cut aluminum extrusions (for making aluminum screens and storm windows) with your compound miter saw. When cutting aluminum extrusions (or other sections that can be cut with a saw blade), position the material so that the blade is cutting through the smallest

Never apply lubricant to the blade while the machine is running.

BLADE

FENCE

FENCE

BLADE

Fig. 39

RIGHT

Fig. 39A

WRONG

16