(V)KC42N Series, (V)KC42P SERIES specifications

The Desa (V)KC42P SERIES and (V)KC42N Series represent a significant advancement in the field of heating solutions, designed to enhance comfort while optimizing energy efficiency. These innovative heating systems are engineered for residential and commercial applications, making them versatile for various environments.One of the standout features of the Desa (V)KC42P and (V)KC42N Series is their advanced control technologies. Equipped with smart thermostatic controls, these units allow users to manage their heating needs with precision. The intuitive user interface provides an easy way to adjust settings, ensuring that the desired temperature is achieved while minimizing energy consumption.

The efficiency of the (V)KC42P and (V)KC42N Series is further enhanced by their state-of-the-art combustion technology. These models utilize a unique burner design that maximizes heat output while reducing emissions. This not only supports environmental sustainability but also ensures that users save on energy costs without compromising performance.

Safety is another paramount feature of these heating systems. The Desa series incorporates multiple fail-safes, including overheat protection and automatic shut-off mechanisms. These features are designed to provide peace of mind for users, knowing that their home or business is equipped with a system that prioritizes safety.

Durability and reliability are also hallmarks of the Desa (V)KC42P and (V)KC42N Series. Constructed with high-quality materials, these units are built to withstand the rigors of daily use while maintaining an aesthetically pleasing design. This ensures they complement any décor while delivering consistent performance across seasons.

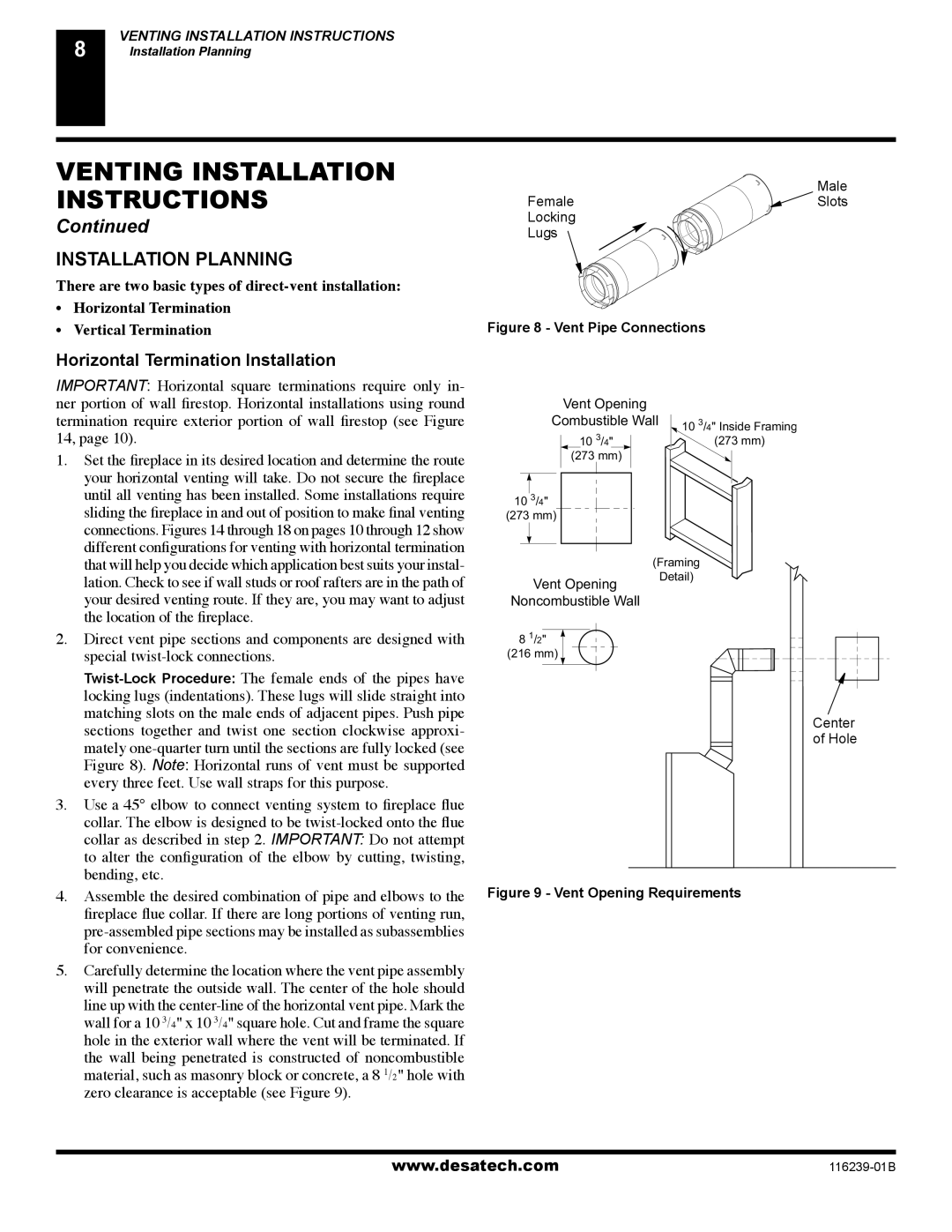

In terms of installation, both series come with flexible options. They can be easily integrated into existing setups, making upgrades or replacements hassle-free. The user-friendly installation procedures reduce downtime, allowing users to enjoy the benefits of their new heating system almost immediately.

Additionally, the (V)KC42P and (V)KC42N Series are designed with versatility in mind. They can accommodate various heating methods, from forced air to radiant heating, making them suitable for different heating preferences and system requirements.

In summary, the Desa (V)KC42P and (V)KC42N Series are engineered to provide superior heating performance, energy efficiency, and safety. With advanced technology, durable construction, and user-friendly features, these heating solutions stand out in the market as reliable options for any heating need.