OUTSIDE OF | SIDE FIREBRICK |

FINISHED SIDE | |

FIREPLACE |

|

GAS LINE

CONDUITREMOVE

KNOCKOUT

REMOVE ![]() INSULATION TEMPORARILY (DO NOT DISCARD)

INSULATION TEMPORARILY (DO NOT DISCARD)

|

| REFRACTORY |

| AFTER REMOVING | KNOCKOUT PLUG |

| REMOVE BY TAPPING | |

| GAS LINE COVER | |

| LIGHTLY WITH A | |

| PLATE, REPLACE | |

| 1/2" DOWEL | |

| SCREWS | |

Figure 13 |

| |

|

|

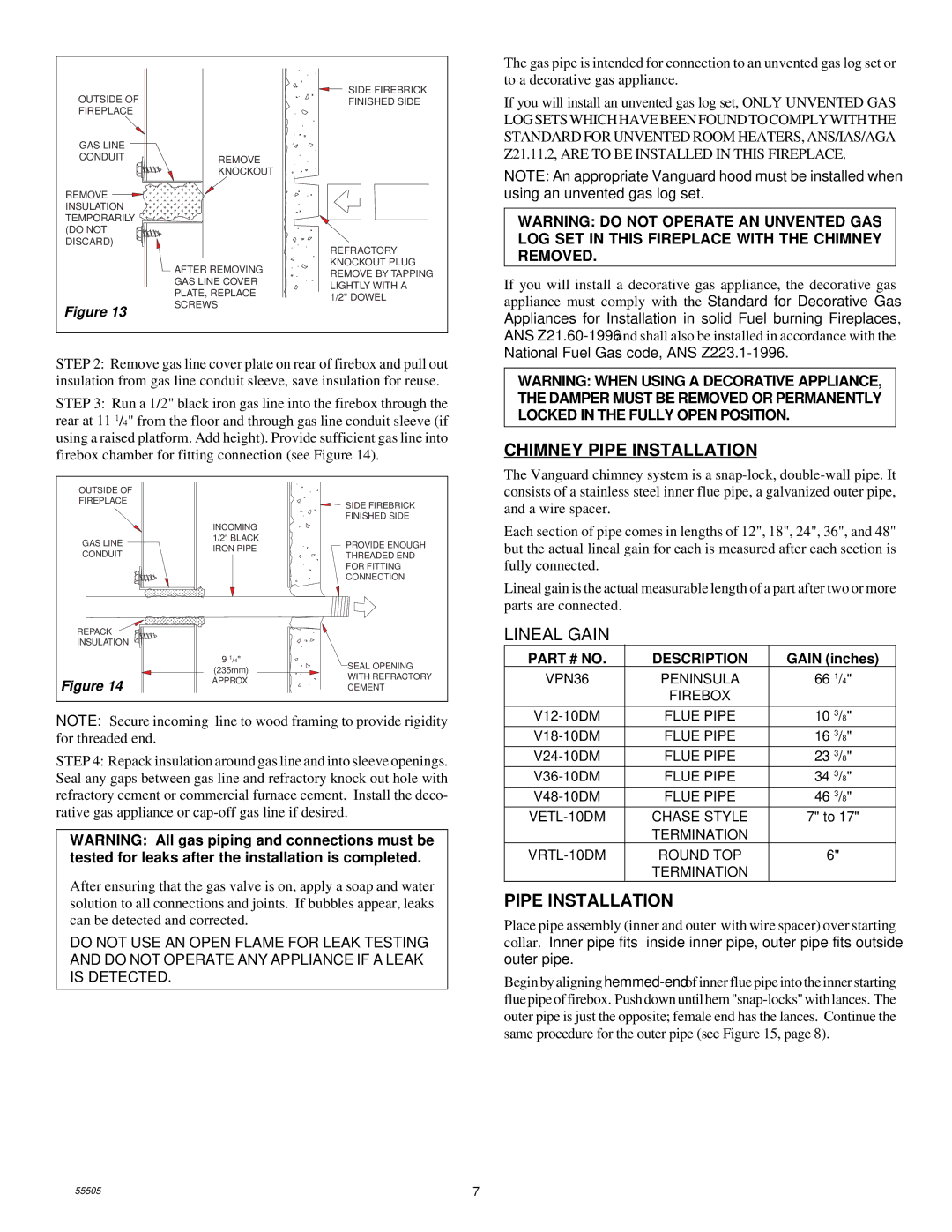

STEP 2: Remove gas line cover plate on rear of firebox and pull out insulation from gas line conduit sleeve, save insulation for reuse.

STEP 3: Run a 1/2" black iron gas line into the firebox through the rear at 11 1/4" from the floor and through gas line conduit sleeve (if using a raised platform. Add height). Provide sufficient gas line into firebox chamber for fitting connection (see Figure 14).

OUTSIDE OF |

|

| |

FIREPLACE |

| SIDE FIREBRICK | |

|

| ||

|

| FINISHED SIDE | |

| INCOMING |

| |

GAS LINE | 1/2" BLACK | PROVIDE ENOUGH | |

IRON PIPE | |||

CONDUIT | THREADED END | ||

| |||

|

| FOR FITTING | |

|

| CONNECTION |

REPACK

INSULATION

91/4"

| (235mm) | SEAL OPENING | |

| WITH REFRACTORY | ||

Figure 14 | APPROX. | ||

CEMENT | |||

|

NOTE: Secure incoming line to wood framing to provide rigidity for threaded end.

STEP 4: Repack insulation around gas line and into sleeve openings. Seal any gaps between gas line and refractory knock out hole with refractory cement or commercial furnace cement. Install the deco- rative gas appliance or

WARNING: All gas piping and connections must be tested for leaks after the installation is completed.

After ensuring that the gas valve is on, apply a soap and water solution to all connections and joints. If bubbles appear, leaks can be detected and corrected.

DO NOT USE AN OPEN FLAME FOR LEAK TESTING AND DO NOT OPERATE ANY APPLIANCE IF A LEAK IS DETECTED.

The gas pipe is intended for connection to an unvented gas log set or to a decorative gas appliance.

If you will install an unvented gas log set, ONLY UNVENTED GAS LOG SETS WHICH HAVE BEEN FOUND TO COMPLY WITH THE STANDARD FOR UNVENTED ROOM HEATERS, ANS/IAS/AGA Z21.11.2, ARE TO BE INSTALLED IN THIS FIREPLACE.

NOTE: An appropriate Vanguard hood must be installed when using an unvented gas log set.

WARNING: DO NOT OPERATE AN UNVENTED GAS LOG SET IN THIS FIREPLACE WITH THE CHIMNEY REMOVED.

If you will install a decorative gas appliance, the decorative gas appliance must comply with the Standard for Decorative Gas

Appliances for Installation in solid Fuel burning Fireplaces, ANS

National Fuel Gas code, ANS

WARNING: WHEN USING A DECORATIVE APPLIANCE, THE DAMPER MUST BE REMOVED OR PERMANENTLY LOCKED IN THE FULLY OPEN POSITION.

CHIMNEY PIPE INSTALLATION

The Vanguard chimney system is a

Each section of pipe comes in lengths of 12", 18", 24", 36", and 48" but the actual lineal gain for each is measured after each section is fully connected.

Lineal gain is the actual measurable length of a part after two or more parts are connected.

LINEAL GAIN

PART # NO. | DESCRIPTION | GAIN (inches) |

VPN36 | PENINSULA | 66 1/4" |

| FIREBOX |

|

|

|

|

FLUE PIPE | 10 3/8" | |

FLUE PIPE | 16 3/8" | |

FLUE PIPE | 23 3/8" | |

FLUE PIPE | 34 3/8" | |

FLUE PIPE | 46 3/8" | |

CHASE STYLE | 7" to 17" | |

| TERMINATION |

|

ROUND TOP | 6" | |

| TERMINATION |

|

PIPE INSTALLATION

Place pipe assembly (inner and outer with wire spacer) over starting collar. Inner pipe fits inside inner pipe, outer pipe fits outside outer pipe.

Begin by aligning

55505 | 7 |