Venting Installation

instructions

Continued

INSTALLATION PLANNING

There are two basic types of

•Horizontal Termination

•Vertical Termination

Horizontal Termination Installation IMPORTANT: Horizontal square terminations require only inner portion of wall firestop. Hori- zontal installations using round termination require exterior portion of wall firestop (see Figure 14, page 12).

1. Set the fireplace in its desired location and |

determine the route your horizontal venting |

will take. Do not secure the fireplace until |

all venting has been installed. Some installa- |

tions require sliding the fireplace in and out |

of position to make final venting connections. |

Figures 14 through 18 on pages 12 through |

14 show different configurations for venting |

with horizontal termination that will help |

you decide which application best suits your |

installation. Check to see if wall studs or roof |

rafters are in the path of your desired venting |

route. If they are, you may want to adjust the |

location of the fireplace. |

2. Direct vent pipe sections and components are |

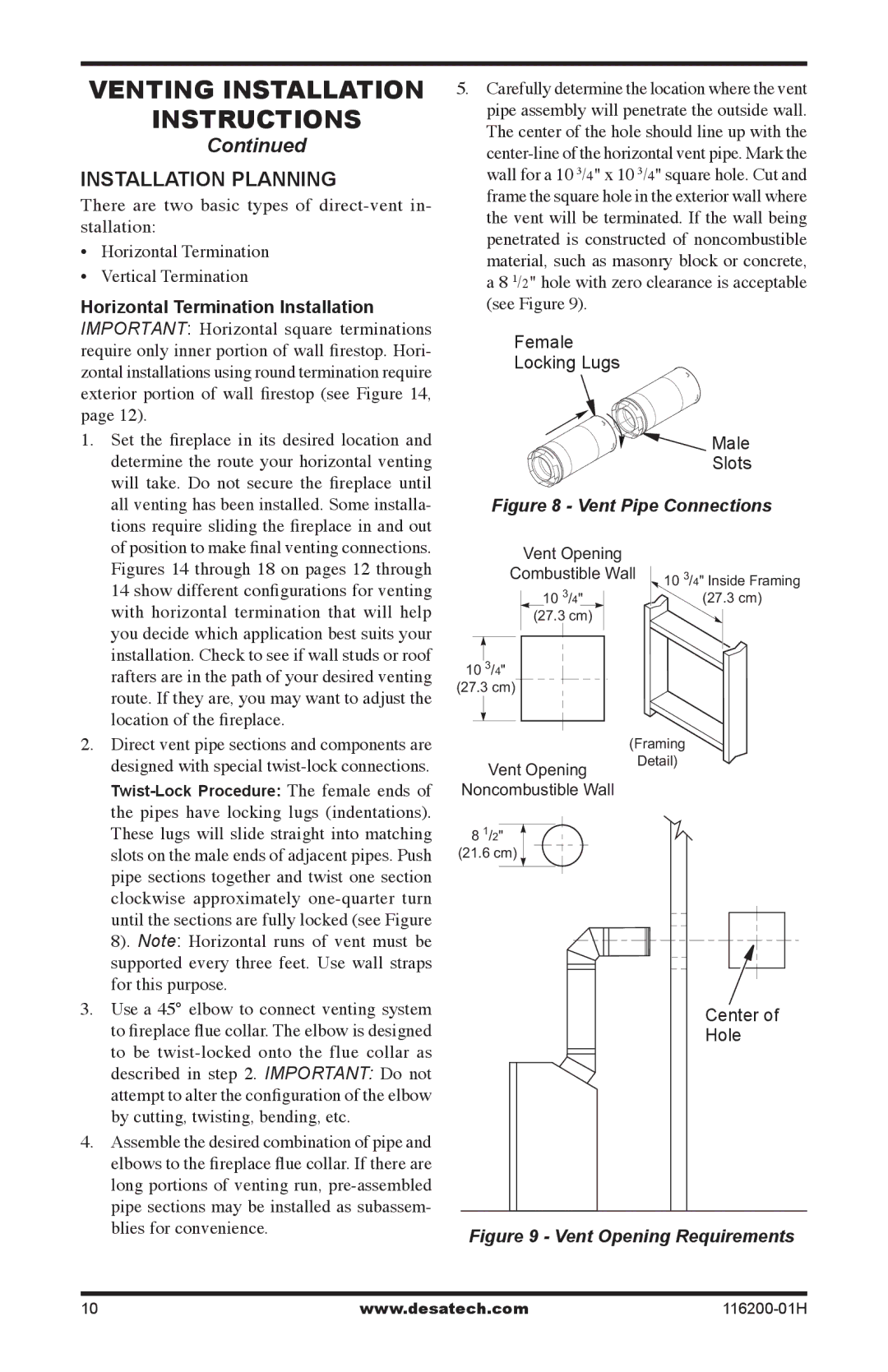

5.Carefully determine the location where the vent pipe assembly will penetrate the outside wall. The center of the hole should line up with the

Female

Locking Lugs

Male

Male

Slots

Figure 8 - Vent Pipe Connections

Vent Opening

Combustible Wall ![]() 10 3/4" Inside Framing

10 3/4" Inside Framing

10 3/4"(27.3 cm)

(27.3 cm)

10 3/4"

(27.3 cm)

(Framing

designed with special |

Vent Opening

Detail)

the pipes have locking lugs (indentations). |

These lugs will slide straight into matching |

slots on the male ends of adjacent pipes. Push |

pipe sections together and twist one section |

clockwise approximately |

until the sections are fully locked (see Figure |

8). Note: Horizontal runs of vent must be |

supported every three feet. Use wall straps |

for this purpose. |

3. Use a 45° elbow to connect venting system |

to fireplace flue collar. The elbow is designed |

to be |

described in step 2. IMPORTANT: Do not |

attempt to alter the configuration of the elbow |

by cutting, twisting, bending, etc. |

4. Assemble the desired combination of pipe and |

elbows to the fireplace flue collar. If there are |

long portions of venting run, |

pipe sections may be installed as subassem- |

blies for convenience. |

Noncombustible Wall

8 1/2" |

(21.6 cm) |

Center of |

Hole |

Figure 9 - Vent Opening Requirements |

10 | www.desatech.com |