VYGF33PRB, VYGF33NRB, FPVF33PRA, FPVF33NRA, VYGF33NRB, VYGF33PRB specifications

Desa VYGF33NRB, VYGF33PRB, and FPVF33PRA are leading models in the domain of innovative heating solutions, featuring state-of-the-art technology and design aimed at efficiency and performance. These heating units are engineered to cater to a variety of spaces while ensuring user-friendly operation and environmental considerations.The VYGF33NRB and VYGF33PRB models are distinguished by their advanced radiant heating technology. They utilize infrared heat, which warms objects and surfaces directly rather than simply heating the air. This method proves to be highly efficient, particularly in large or poorly insulated spaces, as it minimizes energy waste and promotes rapid heating.

Both VYGF33NRB and VYGF33PRB models come equipped with adjustable thermostats, allowing users to maintain precise temperature controls according to their specific needs. This feature complements the energy-saving capabilities of these models, ensuring that they only operate when necessary, thereby reducing overall energy consumption. Furthermore, the sleek, modern design of these models makes them an attractive addition to any indoor or outdoor setting.

The FPVF33PRA and FPVF33NRA, on the other hand, focus on versatility and portability. With lighter designs and built-in mobility features, these units can be easily relocated according to the user's requirements. They incorporate integrated safety mechanisms, such as tip-over switches and overheat protection, ensuring that safety remains a priority even in dynamic environments.

In addition to their heating capabilities, these models are equipped with air filtration technologies that improve indoor air quality. This feature is particularly beneficial in regions where allergens and pollutants can affect health and comfort. The air filtration systems in the FPVF33 series transform heating units into multi-functional appliances, providing not just warmth but also clean air.

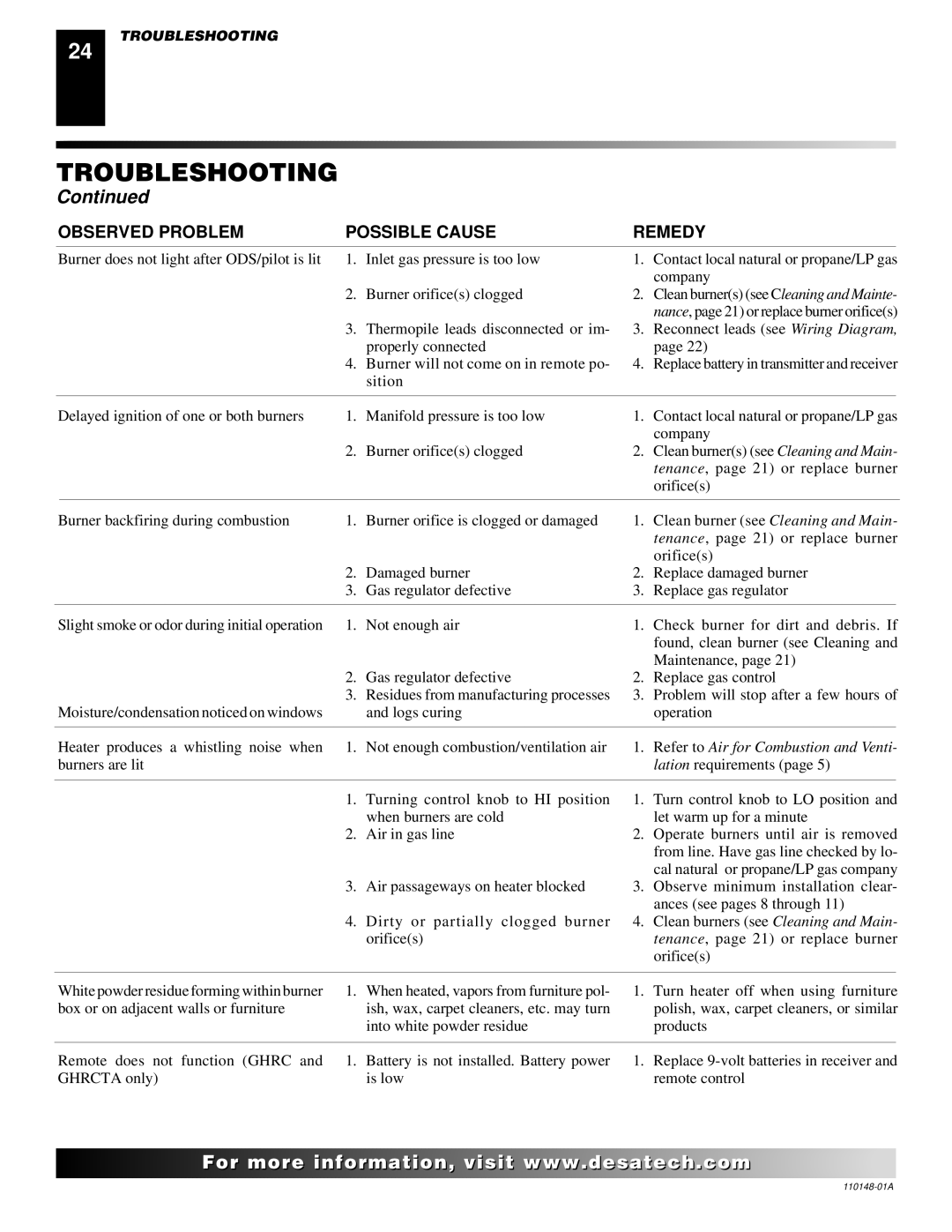

Another noteworthy characteristic is the ease of maintenance that these units offer. Many components are designed for easy access, allowing for routine cleaning and replacement to ensure longevity. These models also feature energy-efficient settings that adapt to environmental conditions, making them suitable for various climates.

In conclusion, the Desa VYGF33NRB, VYGF33PRB, FPVF33PRA, and FPVF33NRA models epitomize the merging of innovative technology with practical utility. Their distinct features such as energy efficiency, advanced heating technology, portability, and air filtration capabilities cater to a wide range of heating needs while promoting a safer, healthier living environment. With these models, users can expect not only comfort but also a commitment to sustainability in their heating solutions.