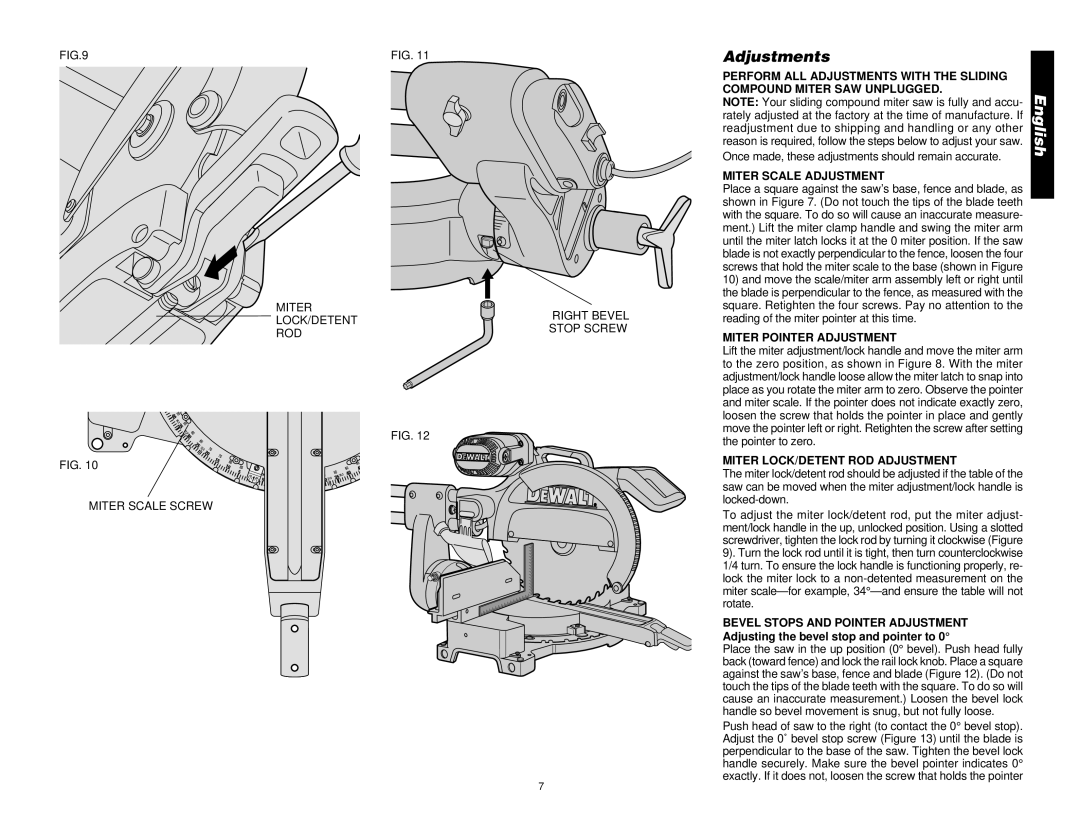

FIG.9 |

| FIG. 11 |

| MITER | RIGHT BEVEL |

| LOCK/DETENT | |

| STOP SCREW | |

| ROD | |

|

|

FIG. 12

FIG. 10

MITER SCALE SCREW

Adjustments

PERFORM ALL ADJUSTMENTS WITH THE SLIDING COMPOUND MITER SAW UNPLUGGED.

NOTE: Your sliding compound miter saw is fully and accu- rately adjusted at the factory at the time of manufacture. If readjustment due to shipping and handling or any other reason is required, follow the steps below to adjust your saw.

Once made, these adjustments should remain accurate.

MITER SCALE ADJUSTMENT

Place a square against the saw’s base, fence and blade, as shown in Figure 7. (Do not touch the tips of the blade teeth with the square. To do so will cause an inaccurate measure- ment.) Lift the miter clamp handle and swing the miter arm until the miter latch locks it at the 0 miter position. If the saw blade is not exactly perpendicular to the fence, loosen the four screws that hold the miter scale to the base (shown in Figure

10)and move the scale/miter arm assembly left or right until the blade is perpendicular to the fence, as measured with the square. Retighten the four screws. Pay no attention to the reading of the miter pointer at this time.

MITER POINTER ADJUSTMENT

Lift the miter adjustment/lock handle and move the miter arm to the zero position, as shown in Figure 8. With the miter adjustment/lock handle loose allow the miter latch to snap into place as you rotate the miter arm to zero. Observe the pointer and miter scale. If the pointer does not indicate exactly zero, loosen the screw that holds the pointer in place and gently move the pointer left or right. Retighten the screw after setting the pointer to zero.

MITER LOCK/DETENT ROD ADJUSTMENT

The miter lock/detent rod should be adjusted if the table of the saw can be moved when the miter adjustment/lock handle is

To adjust the miter lock/detent rod, put the miter adjust- ment/lock handle in the up, unlocked position. Using a slotted screwdriver, tighten the lock rod by turning it clockwise (Figure 9). Turn the lock rod until it is tight, then turn counterclockwise 1/4 turn. To ensure the lock handle is functioning properly, re- lock the miter lock to a

BEVEL STOPS AND POINTER ADJUSTMENT Adjusting the bevel stop and pointer to 0°

Place the saw in the up position (0° bevel). Push head fully back (toward fence) and lock the rail lock knob. Place a square against the saw’s base, fence and blade (Figure 12). (Do not touch the tips of the blade teeth with the square. To do so will cause an inaccurate measurement.) Loosen the bevel lock handle so bevel movement is snug, but not fully loose.

Push head of saw to the right (to contact the 0° bevel stop). Adjust the 0˚ bevel stop screw (Figure 13) until the blade is perpendicular to the base of the saw. Tighten the bevel lock handle securely. Make sure the bevel pointer indicates 0° exactly. If it does not, loosen the screw that holds the pointer

English

7