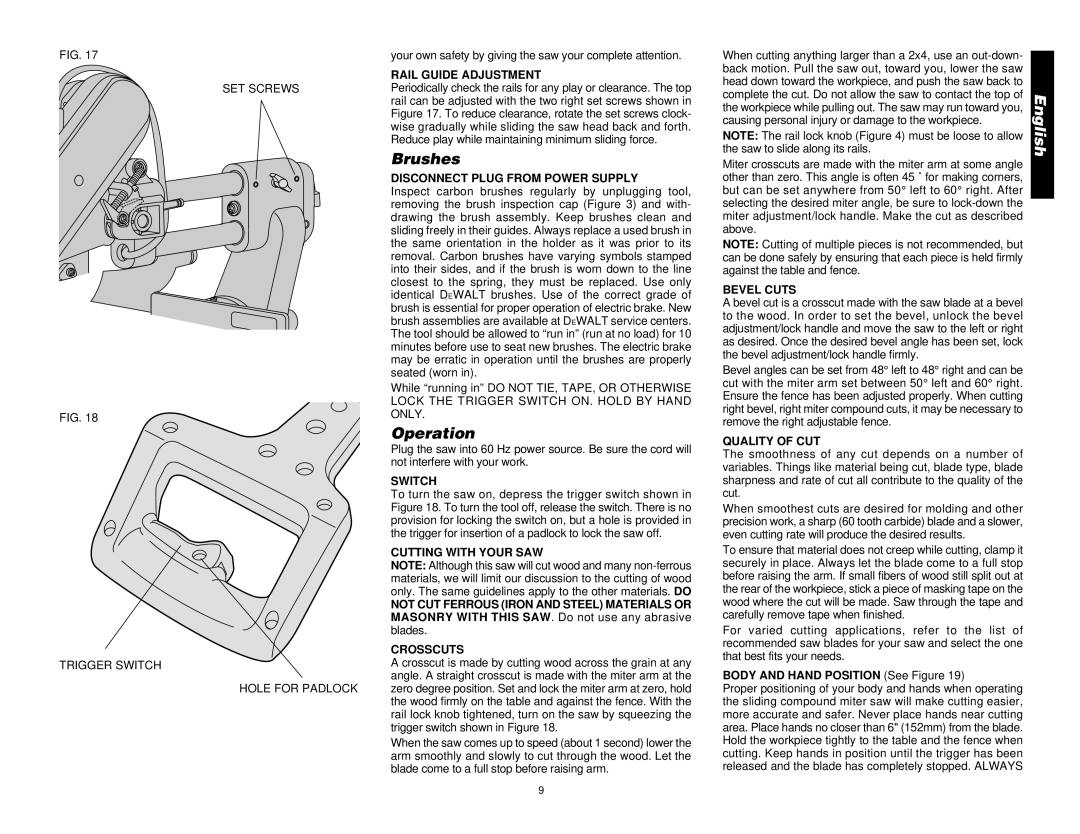

FIG. 17

SET SCREWS

FIG. 18

TRIGGER SWITCH

HOLE FOR PADLOCK

your own safety by giving the saw your complete attention.

RAIL GUIDE ADJUSTMENT

Periodically check the rails for any play or clearance. The top rail can be adjusted with the two right set screws shown in Figure 17. To reduce clearance, rotate the set screws clock- wise gradually while sliding the saw head back and forth. Reduce play while maintaining minimum sliding force.

Brushes

DISCONNECT PLUG FROM POWER SUPPLY

Inspect carbon brushes regularly by unplugging tool, removing the brush inspection cap (Figure 3) and with- drawing the brush assembly. Keep brushes clean and sliding freely in their guides. Always replace a used brush in the same orientation in the holder as it was prior to its removal. Carbon brushes have varying symbols stamped into their sides, and if the brush is worn down to the line closest to the spring, they must be replaced. Use only identical DEWALT brushes. Use of the correct grade of brush is essential for proper operation of electric brake. New brush assemblies are available at DEWALT service centers. The tool should be allowed to “run in” (run at no load) for 10 minutes before use to seat new brushes. The electric brake may be erratic in operation until the brushes are properly seated (worn in).

While “running in” DO NOT TIE, TAPE, OR OTHERWISE LOCK THE TRIGGER SWITCH ON. HOLD BY HAND ONLY.

Operation

Plug the saw into 60 Hz power source. Be sure the cord will not interfere with your work.

SWITCH

To turn the saw on, depress the trigger switch shown in Figure 18. To turn the tool off, release the switch. There is no provision for locking the switch on, but a hole is provided in the trigger for insertion of a padlock to lock the saw off.

CUTTING WITH YOUR SAW

NOTE: Although this saw will cut wood and many

NOT CUT FERROUS (IRON AND STEEL) MATERIALS OR MASONRY WITH THIS SAW. Do not use any abrasive blades.

CROSSCUTS

A crosscut is made by cutting wood across the grain at any angle. A straight crosscut is made with the miter arm at the zero degree position. Set and lock the miter arm at zero, hold the wood firmly on the table and against the fence. With the rail lock knob tightened, turn on the saw by squeezing the trigger switch shown in Figure 18.

When the saw comes up to speed (about 1 second) lower the arm smoothly and slowly to cut through the wood. Let the blade come to a full stop before raising arm.

When cutting anything larger than a 2x4, use an

NOTE: The rail lock knob (Figure 4) must be loose to allow the saw to slide along its rails.

Miter crosscuts are made with the miter arm at some angle other than zero. This angle is often 45 ˚ for making corners, but can be set anywhere from 50° left to 60° right. After selecting the desired miter angle, be sure to

NOTE: Cutting of multiple pieces is not recommended, but can be done safely by ensuring that each piece is held firmly against the table and fence.

BEVEL CUTS

A bevel cut is a crosscut made with the saw blade at a bevel to the wood. In order to set the bevel, unlock the bevel adjustment/lock handle and move the saw to the left or right as desired. Once the desired bevel angle has been set, lock the bevel adjustment/lock handle firmly.

Bevel angles can be set from 48° left to 48° right and can be cut with the miter arm set between 50° left and 60° right. Ensure the fence has been adjusted properly. When cutting right bevel, right miter compound cuts, it may be necessary to remove the right adjustable fence.

QUALITY OF CUT

The smoothness of any cut depends on a number of variables. Things like material being cut, blade type, blade sharpness and rate of cut all contribute to the quality of the cut.

When smoothest cuts are desired for molding and other precision work, a sharp (60 tooth carbide) blade and a slower, even cutting rate will produce the desired results.

To ensure that material does not creep while cutting, clamp it securely in place. Always let the blade come to a full stop before raising the arm. If small fibers of wood still split out at the rear of the workpiece, stick a piece of masking tape on the wood where the cut will be made. Saw through the tape and carefully remove tape when finished.

For varied cutting applications, refer to the list of recommended saw blades for your saw and select the one that best fits your needs.

BODY AND HAND POSITION (See Figure 19)

Proper positioning of your body and hands when operating the sliding compound miter saw will make cutting easier, more accurate and safer. Never place hands near cutting area. Place hands no closer than 6" (152mm) from the blade. Hold the workpiece tightly to the table and the fence when cutting. Keep hands in position until the trigger has been released and the blade has completely stopped. ALWAYS

English

9