English

MAKE DRY RUNS (UNPOWERED) BEFORE FINISH CUTS SO THAT YOU CAN CHECK THE PATH OF THE BLADE. DO NOT CROSS HANDS.

Keep both feet firmly on the floor and maintain proper balance. As you move the miter arm left and right, follow it and stand slightly to the side of the saw blade. Sight through the guard louvers when following a pencil line.

CLAMPING THE WORKPIECE

Turn Off and Unplug Saw

If you cannot secure the workpiece on the table and against the fence by hand, (irregular shape, etc.) or your hand would be less than 6” from the blade, a clamp or other fixture should be used.

For best results us the DW7052 clamp made for use with your saw. It is available through your local retailer or DEWALT service center at extra cost.

Other aids such as spring clamps, bar clamps or

SUPPORT FOR LONG PIECES

Turn Off and Unplug Saw

ALWAYS SUPPORT LONG PIECES

For best results, use the DW7080 extension kit to extend the table width of your saw. Available for purchase from your dealer. Support long workpieces using any convenient means such as sawhorses or similar devices to keep the ends from dropping. The base top is 3.5" tall, allowing a 4x4 or 2 2x4s to be used on a long table or bench.

CUTTING PICTURE FRAMES, SHADOW BOXES AND OTHER FOUR SIDED PROJECTS

To best understand how to make the items listed here, we suggest that you try a few simple projects using scrap wood until you develop a FEEL for your saw.

Your saw is the perfect tool for mitering corners like the one shown in Figure 20. Sketch A in Figure 20 shows a joint made by using the bevel adjustment to bevel the edges of the two boards at 45 degrees each to produce a 90 degree corner. For this joint the miter arm was locked in the zero position and the bevel adjustment was locked at 45 degrees. The wood was positioned with the broad flat side against the table and the narrow edge against the fence. The cut could also be made by mitering right and left with the broad surface against the fence.

CUTTING TRIM MOLDING AND OTHER FRAMES Sketch B in Figure 20 shows a joint made by setting the miter arm at 45 degrees to miter the two boards to form a 90 degree corner. To make this type of joint, set the bevel adjustment to zero and the miter arm to 45 degrees. Once again, position the wood with the broad flat side on the table and the narrow edge against the fence.

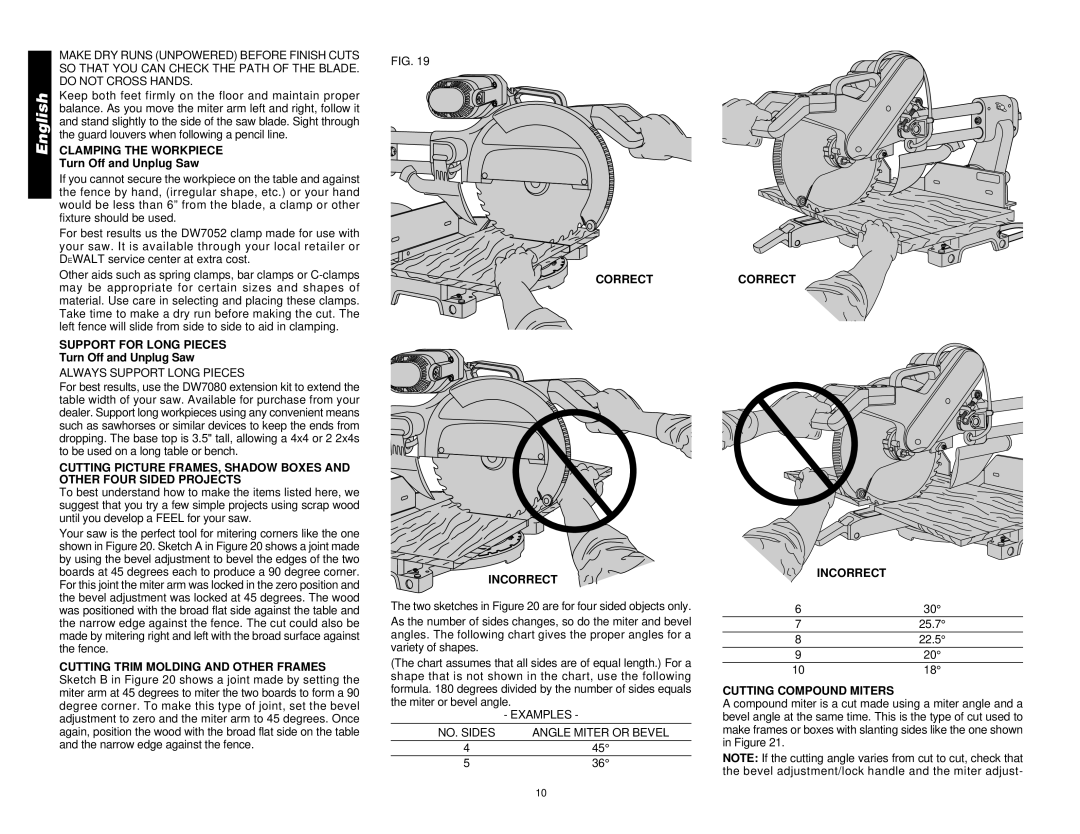

FIG. 19

CORRECT

INCORRECT

The two sketches in Figure 20 are for four sided objects only.

As the number of sides changes, so do the miter and bevel angles. The following chart gives the proper angles for a variety of shapes.

(The chart assumes that all sides are of equal length.) For a shape that is not shown in the chart, use the following formula. 180 degrees divided by the number of sides equals the miter or bevel angle.

- EXAMPLES -

NO. SIDES | ANGLE MITER OR BEVEL |

4 | 45° |

5 | 36° |

CORRECT

INCORRECT

630°

725.7°

822.5°

920°

1018°

CUTTING COMPOUND MITERS

A compound miter is a cut made using a miter angle and a bevel angle at the same time. This is the type of cut used to make frames or boxes with slanting sides like the one shown in Figure 21.

NOTE: If the cutting angle varies from cut to cut, check that the bevel adjustment/lock handle and the miter adjust-

10