OPERATING INSTRUCTIONS

DWash the appliance panels using hot water to which a fat- dissolving agent has been added, dry and polish if neces- sary. No steel brushes, steel or copper wool or similar utensils are to be used.

2.1FINNED PAN RESTS

Use a sponge and lukewarm soapy water or another soft detergent for cleaning. Do not use steel wool or abrasive cleaning agents so as not to damage the enamel. If heavily soiled, the pan rests should be soaked in soapy water over- night.

Finned pan rests made of chrome nickel steel can be washed in a washing machine.

2.2HOTPLATE

From time to time use a steel brush to clean dirt and soot from the plate and grease it lightly with commercial range plate grease. Never use water for cleaning, as this would cause cor- rosion.

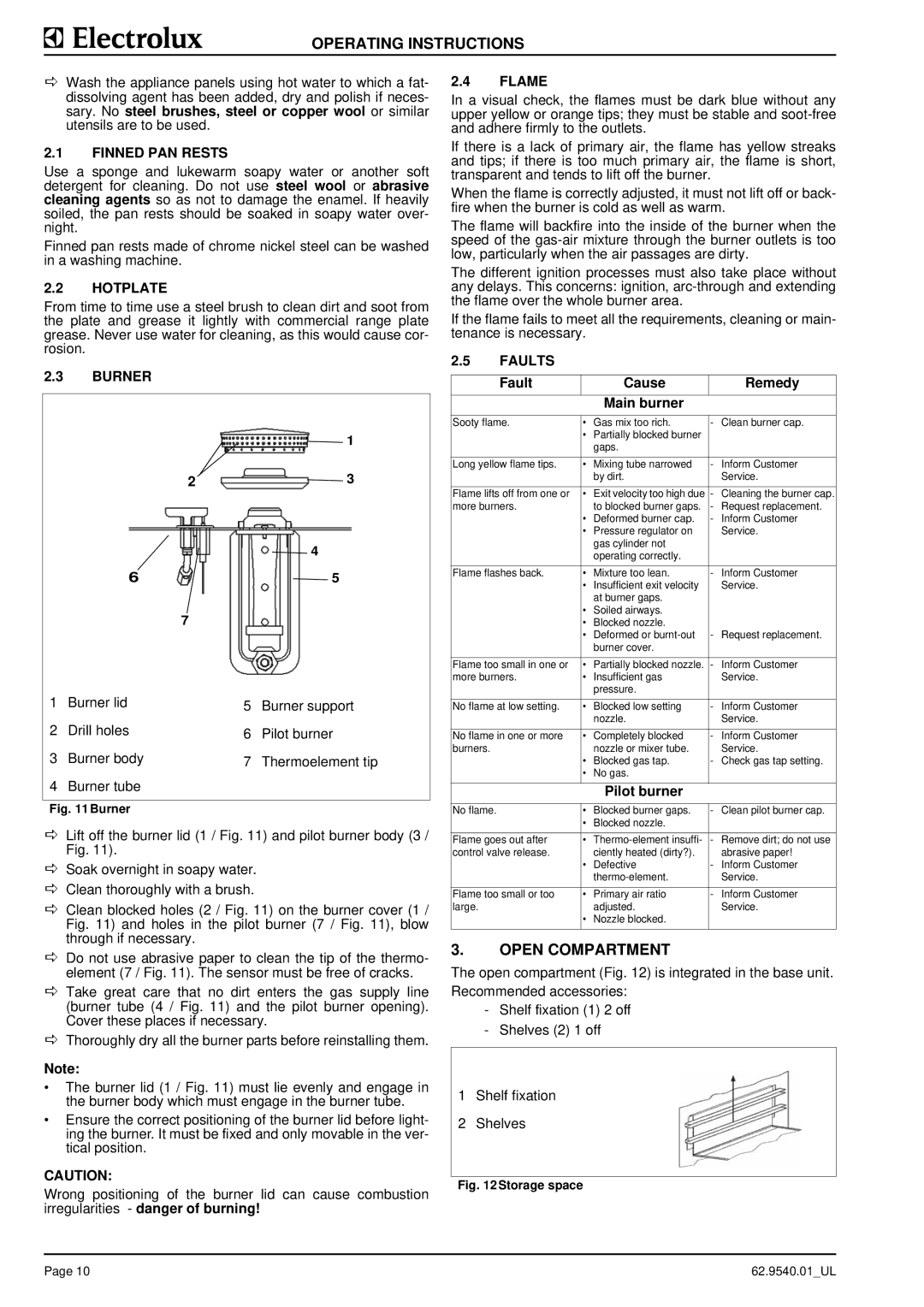

2.3BURNER

1

23

4

6 | 5 |

7

1 | Burner lid | 5 | Burner support |

2 | Drill holes | 6 | Pilot burner |

3 | Burner body | 7 | Thermoelement tip |

4Burner tube

Fig. 11Burner

DLift off the burner lid (1 / Fig. 11) and pilot burner body (3 / Fig. 11).

DSoak overnight in soapy water.

DClean thoroughly with a brush.

DClean blocked holes (2 / Fig. 11) on the burner cover (1 / Fig. 11) and holes in the pilot burner (7 / Fig. 11), blow through if necessary.

DDo not use abrasive paper to clean the tip of the thermo- element (7 / Fig. 11). The sensor must be free of cracks.

DTake great care that no dirt enters the gas supply line (burner tube (4 / Fig. 11) and the pilot burner opening). Cover these places if necessary.

DThoroughly dry all the burner parts before reinstalling them.

Note:

•The burner lid (1 / Fig. 11) must lie evenly and engage in the burner body which must engage in the burner tube.

•Ensure the correct positioning of the burner lid before light- ing the burner. It must be fixed and only movable in the ver- tical position.

CAUTION:

Wrong positioning of the burner lid can cause combustion irregularities - danger of burning!

2.4FLAME

In a visual check, the flames must be dark blue without any upper yellow or orange tips; they must be stable and

If there is a lack of primary air, the flame has yellow streaks and tips; if there is too much primary air, the flame is short, transparent and tends to lift off the burner.

When the flame is correctly adjusted, it must not lift off or back- fire when the burner is cold as well as warm.

The flame will backfire into the inside of the burner when the speed of the

The different ignition processes must also take place without any delays. This concerns: ignition,

If the flame fails to meet all the requirements, cleaning or main- tenance is necessary.

2.5 | FAULTS |

|

|

|

|

|

|

|

|

|

|

| Fault |

| Cause |

| Remedy |

|

|

| Main burner |

|

|

Sooty flame. | • | Gas mix too rich. | - | Clean burner cap. | |

|

| • | Partially blocked burner |

|

|

|

|

| gaps. |

|

|

|

|

|

|

| |

Long yellow flame tips. | • | Mixing tube narrowed | - | Inform Customer | |

|

|

| by dirt. |

| Service. |

|

|

|

|

| |

Flame lifts off from one or | • | Exit velocity too high due | - | Cleaning the burner cap. | |

more burners. |

| to blocked burner gaps. | - | Request replacement. | |

|

| • | Deformed burner cap. | - | Inform Customer |

|

| • | Pressure regulator on |

| Service. |

|

|

| gas cylinder not |

|

|

|

|

| operating correctly. |

|

|

|

|

|

|

| |

Flame flashes back. | • | Mixture too lean. | - | Inform Customer | |

|

| • | Insufficient exit velocity |

| Service. |

|

|

| at burner gaps. |

|

|

|

| • | Soiled airways. |

|

|

|

| • | Blocked nozzle. | - | Request replacement. |

|

| • | Deformed or | ||

|

|

| burner cover. |

|

|

|

|

|

|

| |

Flame too small in one or | • | Partially blocked nozzle. | - | Inform Customer | |

more burners. | • | Insufficient gas |

| Service. | |

|

|

| pressure. |

|

|

|

|

|

|

| |

No flame at low setting. | • | Blocked low setting | - | Inform Customer | |

|

|

| nozzle. |

| Service. |

|

|

|

|

| |

No flame in one or more | • | Completely blocked | - | Inform Customer | |

burners. |

|

| nozzle or mixer tube. |

| Service. |

|

| • | Blocked gas tap. | - | Check gas tap setting. |

|

| • | No gas. |

|

|

|

|

|

|

|

|

|

|

| Pilot burner |

|

|

No flame. |

| • | Blocked burner gaps. | - | Clean pilot burner cap. |

|

| • | Blocked nozzle. |

|

|

|

|

|

|

| |

Flame goes out after | • | - | Remove dirt; do not use | ||

control valve release. |

| ciently heated (dirty?). |

| abrasive paper! | |

|

| • | Defective | - | Inform Customer |

|

|

|

| Service. | |

|

|

|

|

| |

Flame too small or too | • | Primary air ratio | - | Inform Customer | |

large. |

|

| adjusted. |

| Service. |

|

| • | Nozzle blocked. |

|

|

|

|

|

|

|

|

3.OPEN COMPARTMENT

The open compartment (Fig. 12) is integrated in the base unit. Recommended accessories:

-Shelf fixation (1) 2 off

-Shelves (2) 1 off

1Shelf fixation

2Shelves

Fig. 12Storage space

Page 10 | 62.9540.01_UL |