Tank Gauging System

Installation Manual

Page

Installation manual

Rosemount Tank Radar AB

Contents

Field Communication Unit

Remote Display Unit RDU40

BUS Modems

Junction Boxes

Connection to Computer Networks

Mechanical Installation

List of Drawings

Sensor Installation

Technical Data

Recovery of Packing Material

Recovery of Products

TOC-8

Introduction

Installation

General configuration of a TankRadar REX sys- tem

Installation

Manual Overview

Intrinsic Safety

Safety

Explosion Proof

European Atex Directive Information

Radar Unit

Special Conditions for Safe Use

Radar Tank Gauge

Schedule of Limitations

Transmitter Interface Card TIC

Certification label for the Temperature Multiplexer Card TMC

Temperature Multiplexer Card TMC

Certification label for the FF Adaptor Card FFA

FF Adaptor Card FFA

Certification label Atex for the Data Acquisition Unit

Data Acquisition Unit DAU

Approval label for the Remote Display Unit RDU40

Remote Display Unit 40 RDU

Installation Manual

Transmitter Head RTG 3900 REX

Description of 3900 REX

RTG 3900 transmitter head electronics

Transmitter Head Electronics

Analog Processing Card APC

Relay Output Card ROC

Field Communication Card FCC

Internal switch

External switch

Metrological Seal

Antenna Types

Horn Antenna Gauge, RTG

Parabolic Antenna Gauge, RTG

RTG 3950 Still Pipe Gauge

LPG/LNG Gauge, RTG

Local Readout Display

Data Acquisition Unit

DAU

Write Enable/Inhibit Switch

Connecting the Data Acquisition Unit, DAU

Power Supply

Temperature Sensors

Temperature Range

Selecting the temperature range

RDU 40 connected to the REX gauge

Remote Display Unit RDU40

Installation of RDU 40 master and slave

Back of RDU40

Data items

Two RDU 40 connected to the same REX

FCU Enclosure

Field Communication Unit

1 RS232 communication

Communication Ports

2 RS 485 communication

Write Inhibit/Enable Switch

Connection to a PC

Connecting the Field Communication Unit, FCU

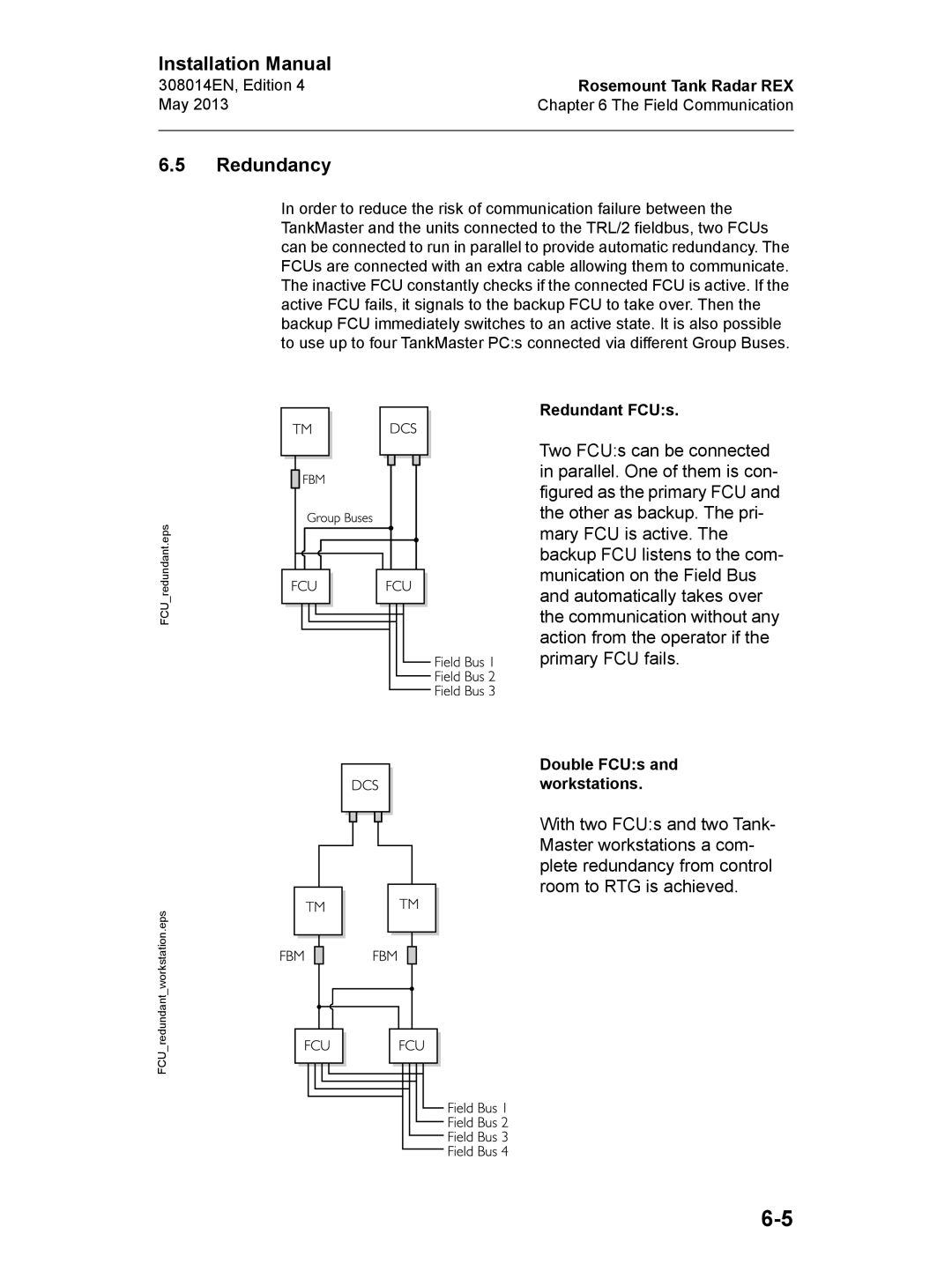

Redundancy

Redundant FCUs, FBMs and workstations

Field Bus Modem

Bus Modems

DIN Rail Mounting

Field Bus Modem

3 TRL/2 Bus

Cable dimension Maximum Length

USB Communication

4 RS 232 Communication

USB Driver Installation

WizardWindowsXP / WizardWindowsXPUSB

Communicating with TankMaster

Operation Front Panel

10 RS 232 Interface

USB Interface

Power supply for RS-232

Specifications Explosion protection

LED indicators

Cable to Host PC

Enraf Bus Modem, EBM

Connecting the Enraf Bus Modem

Configuration

System Type Required Steps Optional Steps Described below

Installation Manual

Junction Boxes

Integrated Junction Box, JBi

Explosion Approval

Cable Inlets RTG

Design

2 JB 140-11 for EEx e environments

1 JB 140-15 for EEx i environments

Conduit outlets

Junction Boxes with Conduit Outlets

Junction Box JBT

Connection of Temperature Sensors

Junction Box JB 36/42

Connection of temperature sensors to JB 36/42 via cable

Connect to the FCU for Quick Updates

Connection to Computer Networks

Connect to TankMaster for Inventory Data

Connection to Computer Networks May

Installation Requirements

Mechanical Installation

10-1

Mounting a Horn Antenna Gauge

Free Space Requirements

10-2

10-3

Dimensions

10-4

Installation on the tank

10-5

Mounting the Parabolic Antenna Gauge

10-6

Inclination

Inclination Flange Ball model T30

Maximum inclination of flange towards the tank center

10-7

Inclination Flange Ball model T38-W

10-8

Free space requirements

10-9

Recommended Installation

10-10

Socket Requirements

Mounting the Flange Ball model T30

10-11

Mounting the Flange Ball model T38-W

10-12

10-13

Mounting the Antenna

10-14

10-15

10-16

10-17

10-18

10-19

10-20

Mounting a Still Pipe Gauge

Introduction

Still Pipe Requirements

10-21

Antenna size mm Pipe

Flange Requirements

10-22

Pipe Dimension Inch Max Area

Free space requirements RTG 3950 Fixed Version

10-23

10-24

Installation of the 3950 Fixed Version on the tank

10-25

10-26

10-27

Free space requirements RTG 3950 Inclined Version

10-28

10-29

10-30

Installation of the RTG 3950 Inclined Version

Mount the antenna on the lid

10-31

10-32

10-33

10-34

10-35

Mount the Waveguide

Connection

10-36

10-37

10-38

Temperature and Pressure Measurement

Mounting a LPG/LNG Gauge

Still Pipe

14. Still Pipe requirements

10-39

Reference Pin and Reflector

10-40

16. Mounting of reflector on pipe 4 inch SCH

10-41

Extension Pipe for Minimum Distance

10-42

10-43

10-44

10-45

10-46

Electrical Installation of the REX Gauges

Cabling for Power Supply

11-1

11-2

115 VAC 60 VAC

60 VDC 24 VDC

11-3

Cabling for TRL/2 Bus

Grounding

11-4

Connecting the Radar Tank Gauge

Terminated

11-5

Cable Outputs

11-6

Option W12 connection

Integrated Junction Box

11-7

Wiring

Intrinsically safe side EEx

Connection Description

Non-Intrinsically safe side EEx e

11-8

Options

11-9

Analog output passive Connection Description

Analog output active Connection Description

11-10

11-11

Tiway Connection Description

11-12

Tiway bus +

Tiway bus

11-13

Power

11.5.5 TRL/2 Bus

11-14

Relays

11-15

Normally Closed Normally Open

11-16

Analog Output

11-17

11-18

Connecting the Temperature Sensors

Spot Elements

Sensor

11-19

Average/Multiple Spot elements

Sensor Connection

Analog Inputs

11-20

Hart Slaves

11-21

11.5.11 DAU/RDU

11-22

Sensor Installation

Temperature Sensors

12-1

12-2

Installation of Multiple Spot Temperature sensors

Example

12-3

12-4

Sensor Installation May 12-5

Mechanical Installation

12-5

Water Level Sensor

Tank geometry for the Water Level Sensor

12-6

12-7

Upper Range Value 20 mA = LA + Lower Range Value 4 mA =

Tank Zero Level

Water Zero Level is above the Tank Zero Level

12-8

Mechanical Installation Drawings TankRadar REX

List of Drawings

13-1

Electrical installation

13-2

Field Bus Modem, FBM

Field Communication Unit, FCU

13-3

Data Acquisition Unit, Sdau

Remote Display Unit, RDU

Temperature / WLS sensors

13-4

Junction Boxes JB

Technical Data

14-1

14.1 RTG

Analog Inputs

14-2

14.1.3 Analog Output

14-3

14.2 RTG

14-4

14.3 RTG

14-5

14.4 RTG

14-6

14.5 RTG

14-7

Data Acquisition Unit, DAU

14-8

View/Software

14-9

Electrical

Mechanical

TRL/2

14-10

Numerics

Index-1

Index May

Index-2

May Index Grounding Potential equalizing network Group Bus

Index-3

Index-4

Radar beam

Index-5

Index-6

Supply voltage switch Field Communication Unit

Index-7

Index-8

Page

Emerson Process Management

Rosemount Tank Gauging local representative