3. Level/Interface. A second float may be added below the first one, and the second output will be calibrated automatically. The second time interval is measured in the same manner as the first and added to the first to derive the position of the heavier float.

The same six inch dead zone applies to the measurement of the second level although the reasons are different. This will typically correspond to a physical separation of the two floats by approximately three inches. The float size, geometry, magnetic strength all play a factor in how close the two floats can get without interfering with each other.

SECTION 3. Installation and Wiring

3.0 Strap-On Transmitter Installation

CAUTION:

During installation, do not attempt to twist or turn the head of the transmitter. Damage to the detector assembly may occur if the head is rotated . If the head is loose, please notify the factory.

The

If a transmitter is being purchased for an interface gage, the calibration for the probe should be done in the field to ensure a proper control room

reading. For long transmitters it may be desirable for the operator to have the electronics housing mounted at the bottom of the gage for easy access.

THIS MUST BE SPECIFIED AT TIME OF PURCHASE.

Installation Note (European):

The cable entry devices and blanking elements of unused apertures shall be of a certified flameproof type, suitable for the conditions of use and correctly installed.

3.1 Standalone Transmitter Installation

The

The magnetic float used in the

The magnetic float can be changed out at any time to accommo- date the processes being measured. The float stop, located at the bottom of the transmitter, can be removed to allow the float to slide off the sensor tube.

PLEASE NOTE:

If using a transmitter configured for dual level output or interface measurements, remember to slide the float with the lightest grav- ity range first.

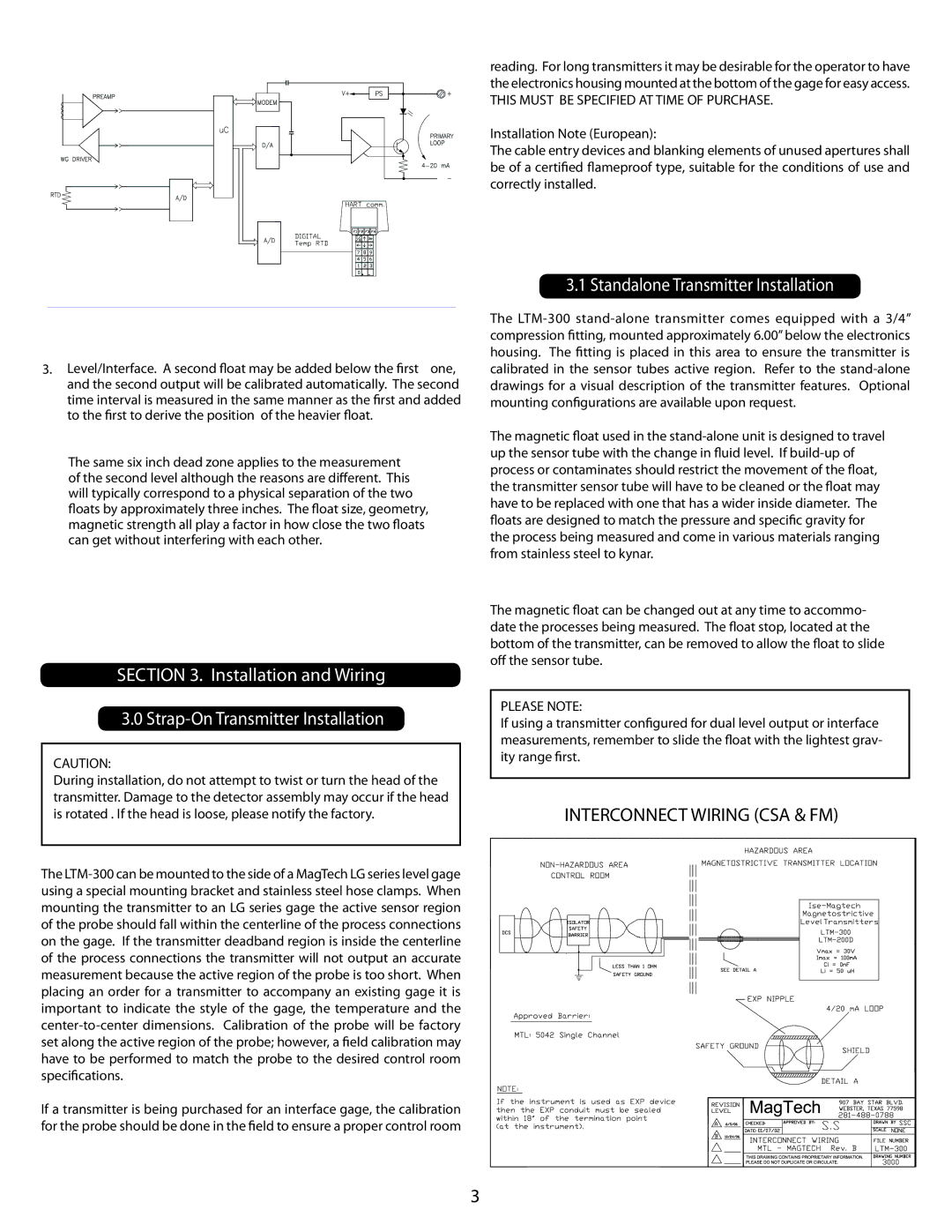

INTERCONNECT WIRING (CSA & FM)

3