3.2Recommended Wiring, Single Loop

SECTION 4. Specifications

4.0 Transmitter Electrical Specifications

Supply Voltage: | 15 to 36 VDC | |

Repeatability: | .005% of full scale or .010”, | |

|

| whichever is greater |

.01% of full scale or .030”, | ||

|

| whichever is greater |

Level Sensor Accuracy: | .01% of full scale or .020”, | |

|

| whichever is greater |

Analog Output Resolution: .025% of full scale, (1) 4/20 mA | ||

|

| primary level. |

Output: | One | |

|

| Level Option: Two Digital |

|

| Outputs: Temperature and/or |

|

| Interface via HART only. |

Calibration: |

| Zero and span field adjustable |

|

| with push buttons or HART. |

|

| Secondary level is auto- |

|

| connect. Temperature is |

|

| configured via HART or AMS |

|

| only. |

Diagnostics: |

| On board diagnostics for |

|

| troubleshooting via HART or |

|

| AMS |

Dampening: |

| 1 to 25 seconds (field |

|

| adjustable) via HART |

Oper. Temp. (electronics) | ||

Housing: | Explosion Proof, Dual | |

| Compartment, H” NPT, Epoxy | |

| Coated Aluminum | |

Polarity Protection: |

| Diode in series with the loop |

Hazardous Location Approvals: FM - Exp Cl l , Div. I Grp. B C D, | ||

|

| Cl II Grp. E F G, Cl III |

CSA - Ex ia (Intrinsically Safe): Cl I, Div. I, Grp. C D | ||

Exp (Expl. Proof): Cl I, Div. I, Grp. B C D, Cl II, Grp. E F G, Cl III | ||

IECEx (Expl. Proof): Ex d IIC T4 |

| |

Atex (Expl. Proof): EEx d IIC T4 | Ex II 2 G | |

Ambient Temp. Range | |

Humidity Limits: | SAMA PMC |

Vibration Limits: | SAMA PMC |

RFI Limits: | SAMA PMC |

| MHz up to 30V/m |

4.1 Transmitter Sensor Tube | |

Material: | 316ss standard, optional |

| Hastalloy, Monel, Kynar coated |

Operating Temperature: | |

Maximum Pressure: | 2000 psig @ 300°F |

Range: | 12” to 30 ft. |

SECTION 5.0 Calibration

5.0 LTM-300 Output Configurations

The

Configurations two and three have independent calibration as well as independent outputs. These configurations have the capability for calibration and measurement using a HART protocol communications system. The HART specifications and conditions will be discussed in detail under the HART COMMUNICATION section of the manual. The temperature range is factory set from

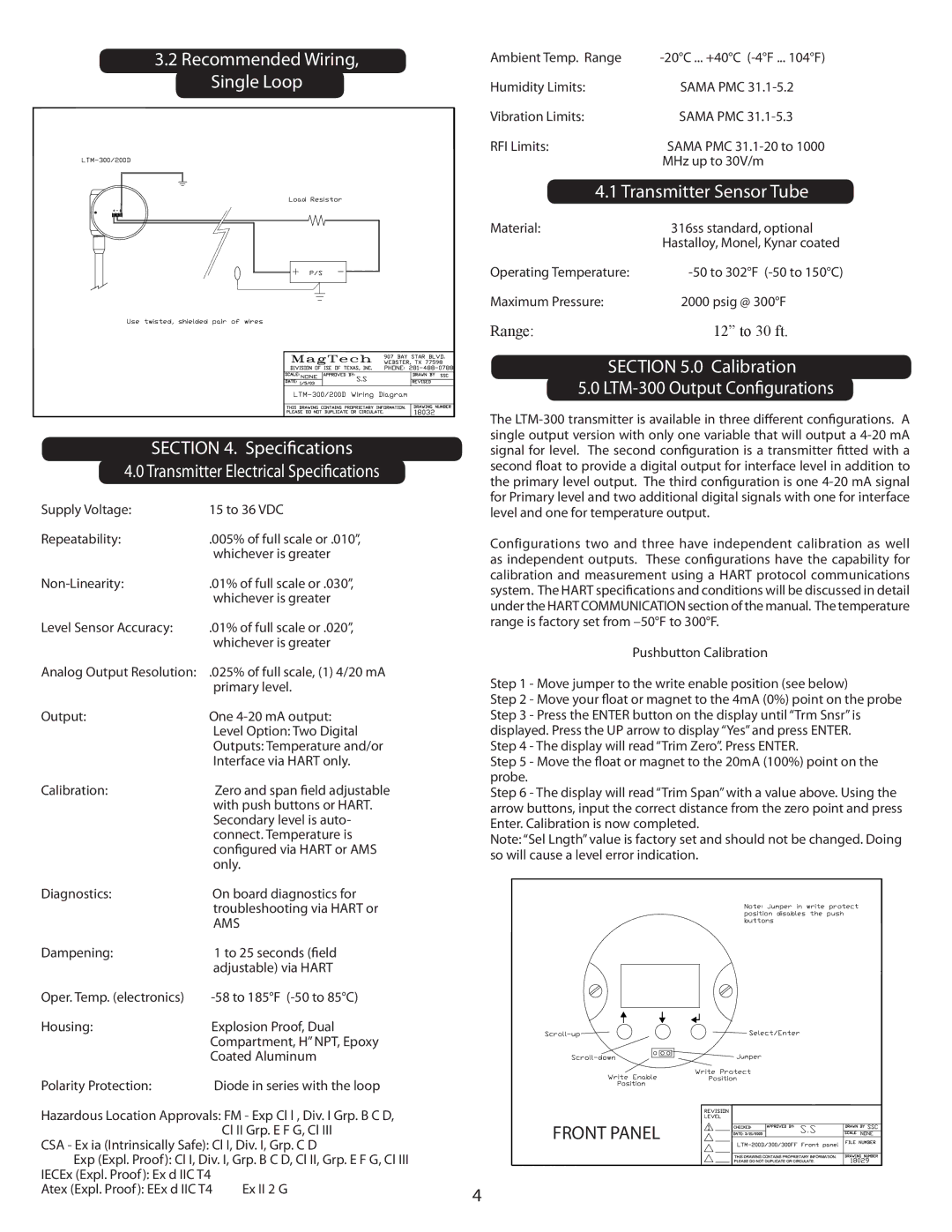

Pushbutton Calibration

Step 1 - Move jumper to the write enable position (see below)

Step 2 - Move your float or magnet to the 4mA (0%) point on the probe Step 3 - Press the ENTER button on the display until “Trm Snsr” is displayed. Press the UP arrow to display “Yes” and press ENTER.

Step 4 - The display will read “Trim Zero”. Press ENTER.

Step 5 - Move the float or magnet to the 20mA (100%) point on the probe.

Step 6 - The display will read “Trim Span” with a value above. Using the arrow buttons, input the correct distance from the zero point and press Enter. Calibration is now completed.

Note: “Sel Lngth” value is factory set and should not be changed. Doing so will cause a level error indication.

FRONT PANEL |

4