Installation, Operation & Maintenance Manual

IP262/Z0, Rev. AB

February 2012 | MSL600 |

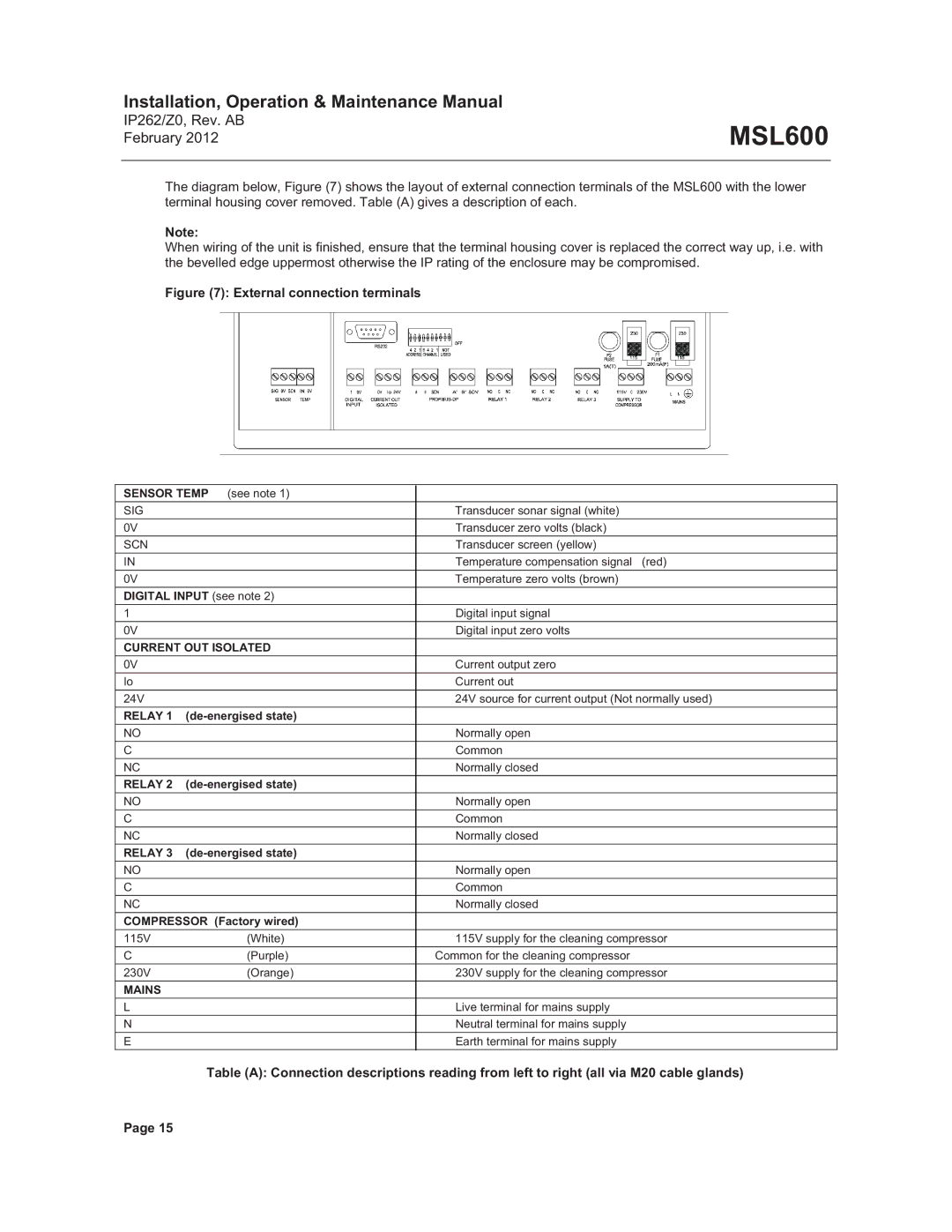

The diagram below, Figure (7) shows the layout of external connection terminals of the MSL600 with the lower terminal housing cover removed. Table (A) gives a description of each.

Note:

When wiring of the unit is finished, ensure that the terminal housing cover is replaced the correct way up, i.e. with the bevelled edge uppermost otherwise the IP rating of the enclosure may be compromised.

Figure (7): External connection terminals

SENSOR TEMP | (see note 1) |

|

SIG |

| Transducer sonar signal (white) |

0V |

| Transducer zero volts (black) |

SCN |

| Transducer screen (yellow) |

IN |

| Temperature compensation signal (red) |

0V |

| Temperature zero volts (brown) |

DIGITAL INPUT (see note 2) |

| |

1 |

| Digital input signal |

0V |

| Digital input zero volts |

CURRENT OUT ISOLATED |

| |

0V |

| Current output zero |

Io |

| Current out |

24V |

| 24V source for current output (Not normally used) |

RELAY 1 |

| |

NO |

| Normally open |

C |

| Common |

NC |

| Normally closed |

RELAY 2 |

| |

NO |

| Normally open |

C |

| Common |

NC |

| Normally closed |

RELAY 3 |

| |

NO |

| Normally open |

C |

| Common |

NC |

| Normally closed |

COMPRESSOR (Factory wired) |

| |

115V | (White) | 115V supply for the cleaning compressor |

C | (Purple) | Common for the cleaning compressor |

230V | (Orange) | 230V supply for the cleaning compressor |

MAINS |

|

|

L |

| Live terminal for mains supply |

N |

| Neutral terminal for mains supply |

E |

| Earth terminal for mains supply |

Table (A): Connection descriptions reading from left to right (all via M20 cable glands)

Page 15