| Installation, Operation & Maintenance Manual |

MSL600 | IP262/Z0, Rev. AB |

February 2012 | |

|

|

3.4 Transducer connections

The MSL600 is housed in an ABS enclosure rated to IP66. The lower section of the housing is for cable connections and the upper part has the LCD and keypad controls.

It is not necessary, or advisable, to remove the lid of the upper part of the enclosure. There are no user serviceable parts inside.

All field wiring connections are accessible by removing the lower lid, which is secured by four screws. Inside the terminal area, all connections are made using screw terminals. All terminal blocks are suitable for wires 0.5mm2 to 2.5mm2 (26 to 12 AWG). Insulation should be stripped back 7.0mm (0.25 inches).

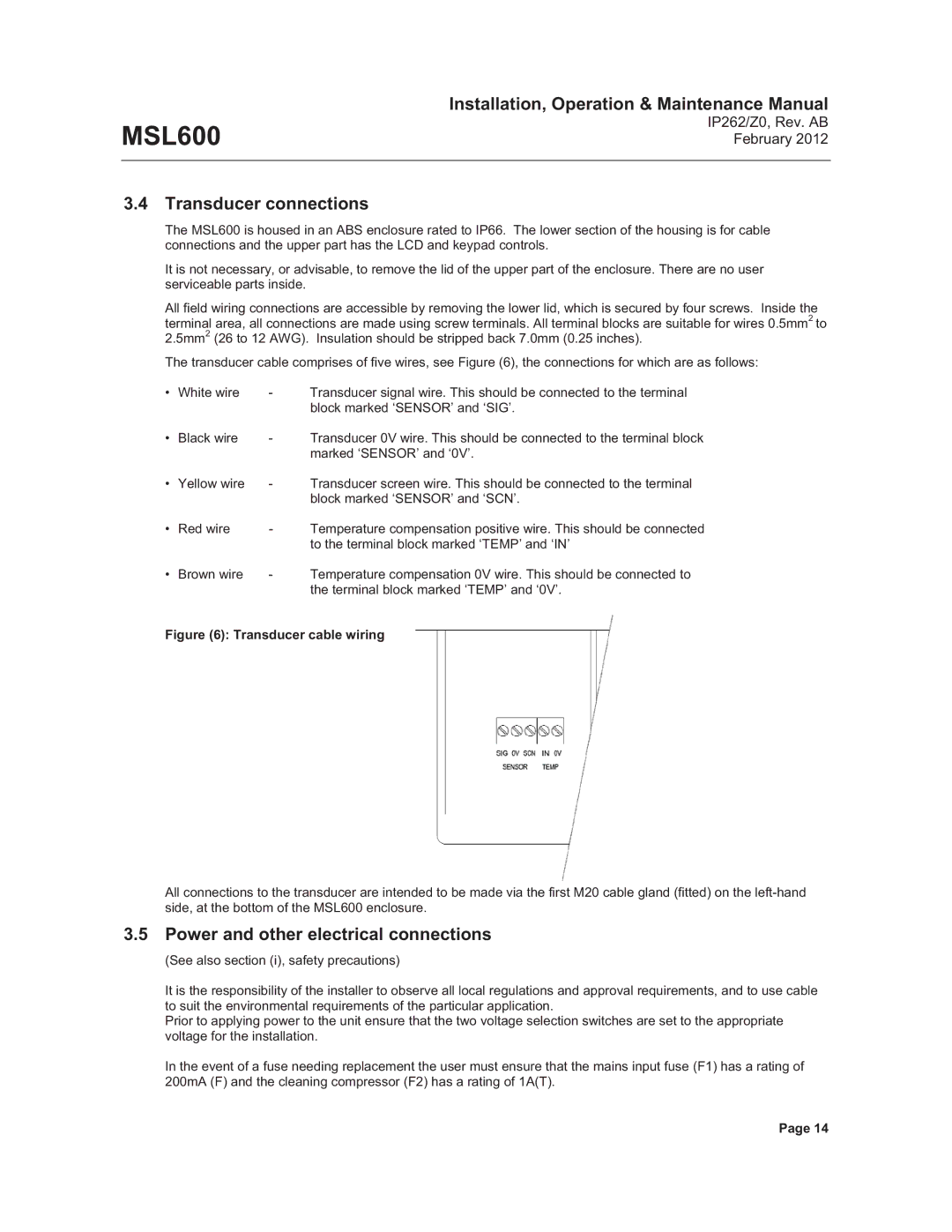

The transducer cable comprises of five wires, see Figure (6), the connections for which are as follows:

• | White wire | - | Transducer signal wire. This should be connected to the terminal |

|

|

| block marked ‘SENSOR’ and ‘SIG’. |

• | Black wire | - | Transducer 0V wire. This should be connected to the terminal block |

|

|

| marked ‘SENSOR’ and ‘0V’. |

• | Yellow wire | - | Transducer screen wire. This should be connected to the terminal |

|

|

| block marked ‘SENSOR’ and ‘SCN’. |

• | Red wire | - | Temperature compensation positive wire. This should be connected |

|

|

| to the terminal block marked ‘TEMP’ and ‘IN’ |

• | Brown wire | - | Temperature compensation 0V wire. This should be connected to |

|

|

| the terminal block marked ‘TEMP’ and ‘0V’. |

Figure (6): Transducer cable wiring

All connections to the transducer are intended to be made via the first M20 cable gland (fitted) on the

3.5 Power and other electrical connections

(See also section (i), safety precautions)

It is the responsibility of the installer to observe all local regulations and approval requirements, and to use cable to suit the environmental requirements of the particular application.

Prior to applying power to the unit ensure that the two voltage selection switches are set to the appropriate voltage for the installation.

In the event of a fuse needing replacement the user must ensure that the mains input fuse (F1) has a rating of 200mA (F) and the cleaning compressor (F2) has a rating of 1A(T).

Page 14