VENTING AND INSTALLATION

Vent System Approvals

Figure 8 shows the vent termination caps and systems approved for use with these models. Approved vent system terminations are labeled for identification. 3-inch diameter listed flexible aluminum or stainless steel gas vent is used for both the incoming combustion air and exhaust vent pipes. NO OTHER VENTING SYSTEMS OR COMPONENTS MAY BE USED. Detailed installation instructions are included with each vent termination kit and should be used in conjunction with this manual.

Horizontal Venting

The vent system on this model CANNOT be terminated horizontally.

Vertical Venting

The inlet and exhaust vent pipes MUST be connected to the proper collars on the unit AND to the termination cap or the unit will not operate. The intake vent collar is identified by a stamped “I” on the top collar sliding vent plate assembly.

WARNING: MAJOR U.S. BUILDING CODES SPECIFY MINIMUM CHIMNEY AND/OR VENT HEIGHT ABOVETHE ROOFTOP.THESEMINIMUMHEIGHTS ARE NECESSARY IN THE INTEREST OF SAFETY. SEE FIGURES 8 THROUGH 10 FOR MINIMUM HEIGHTS, PROVIDED THE TERMINATION CAP IS AT LEAST

Note: This also pertains to vertical vent systems installed on the outside of the building.

WARNING: THE EXHAUST PIPE MUST ONLY BE CONNECTED TO THE EXHAUST STARTING COLLAR OF THE UNIT AND TO THE EXHAUST COLLAR OF THE TERMINATION CAP.

THE INLET AIR PIPE MUST ONLY BE CONNECTED TO THE INLET AIR STARTING COLLAR OF THE UNIT AND TO THE INLET AIR COLLAR OF THE TERMINATION CAP. BOTH THE INLET VENT AND THE FLUE VENT MUST BE CONNECTED FROM THE INSERT TO THE VENT TERMINATION CAP.

NOTE: The minimum vertical vent rise is 12 feet and the maximum vertical vent rise is 35 feet. These dimensions are measured from the starting collars of the unit to the end of the last section of vent pipe. See Figure 8.

NOTE: The damper of the masonry chimney may need to be removed to allow installation of the

When installing into a zero clearance, factory built

Connecting the Vent Pipe

Caution: Sharp edges. Always use gloves when installing.

Install the

Attach the

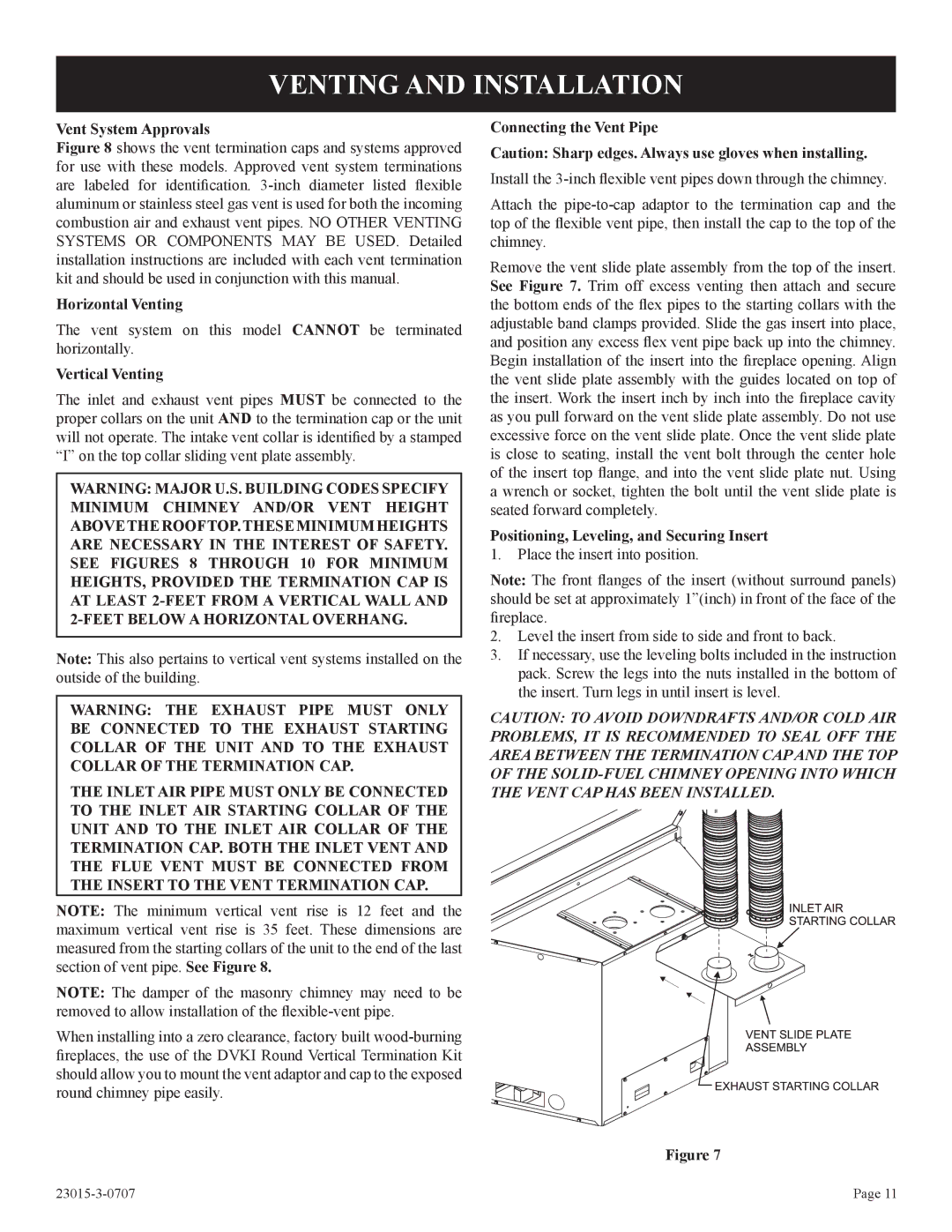

Remove the vent slide plate assembly from the top of the insert. See Figure 7. Trim off excess venting then attach and secure the bottom ends of the flex pipes to the starting collars with the adjustable band clamps provided. Slide the gas insert into place, and position any excess flex vent pipe back up into the chimney. Begin installation of the insert into the fireplace opening. Align the vent slide plate assembly with the guides located on top of the insert. Work the insert inch by inch into the fireplace cavity as you pull forward on the vent slide plate assembly. Do not use excessive force on the vent slide plate. Once the vent slide plate is close to seating, install the vent bolt through the center hole of the insert top flange, and into the vent slide plate nut. Using a wrench or socket, tighten the bolt until the vent slide plate is seated forward completely.

Positioning, Leveling, and Securing Insert

1.Place the insert into position.

Note: The front flanges of the insert (without surround panels) should be set at approximately 1”(inch) in front of the face of the fireplace.

2.Level the insert from side to side and front to back.

3.If necessary, use the leveling bolts included in the instruction pack. Screw the legs into the nuts installed in the bottom of the insert. Turn legs in until insert is level.

CAUTION: TO AVOID DOWNDRAFTS AND/OR COLD AIR PROBLEMS, IT IS RECOMMENDED TO SEAL OFF THE AREA BETWEEN THE TERMINATION CAP AND THE TOP OF THE

Figure 7

Page 11 |