Drive Chain

The drive chain will stretch with use and will require periodic adjustments. To check the chain tension, remove the chain guard and measure the slack.

The amount of slack in the chain should not exceed

Inspect the drive and axle sprockets for worn, damaged or broken teeth. Replace as needed. Inspect the chain links for damaged, worn or loose rivets. Repair or replace as needed.

hours of operation, or more frequently if needed, with a high quality chain lubricant.

Throttle Lever

The throttle lever is located beside the right- handlebar grip and is operated by using the right- hand thumb. The lever is spring loaded and will return to the idle position when you remove your thumb from the lever. To accelerate the unit, simply press the lever forward to open the throttle slide in the carburetor. To slow the unit, reduce the pressure on the lever or remove your thumb and the throttle will return to the idle position automatically.

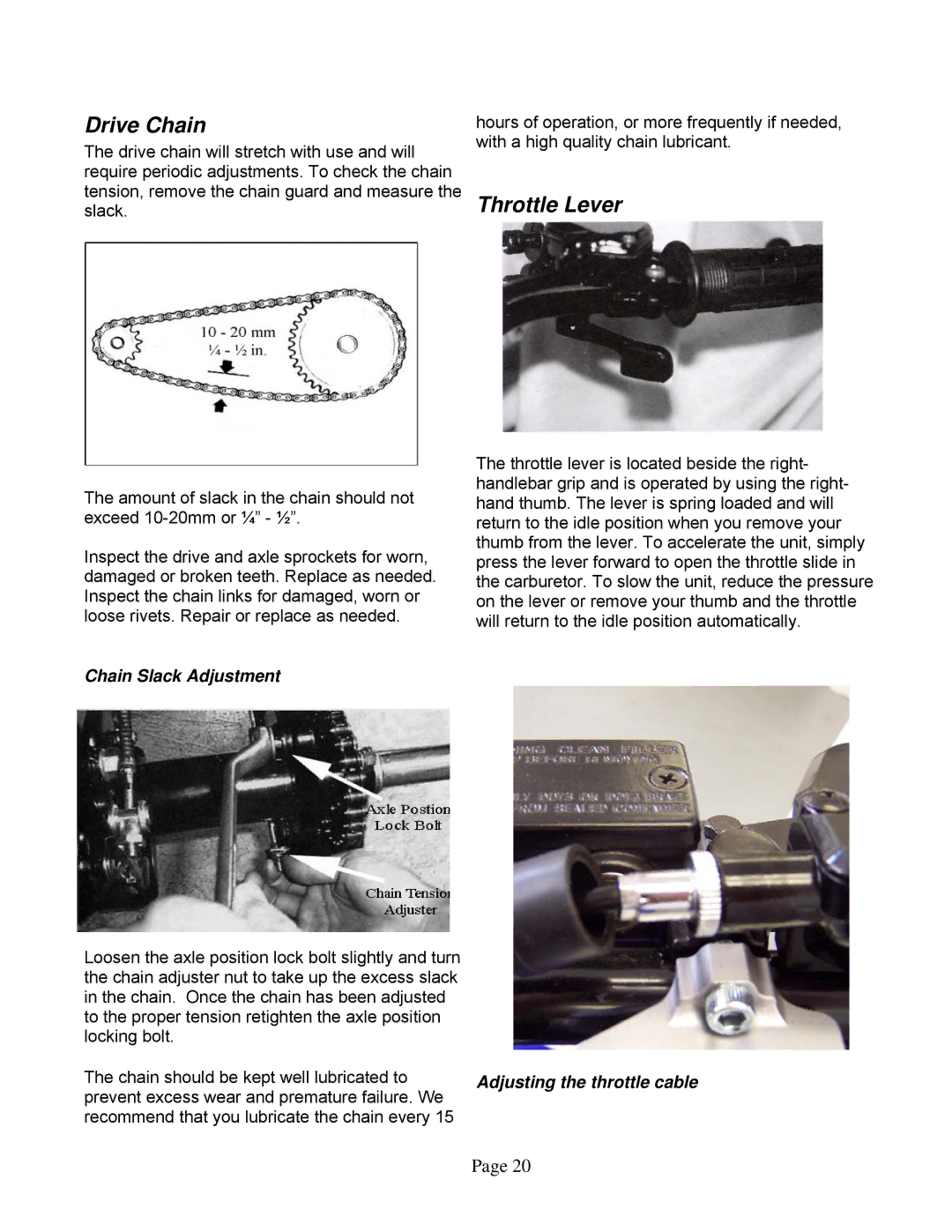

Chain Slack Adjustment

Loosen the axle position lock bolt slightly and turn the chain adjuster nut to take up the excess slack in the chain. Once the chain has been adjusted to the proper tension retighten the axle position locking bolt.

The chain should be kept well lubricated to | Adjusting the throttle cable |

prevent excess wear and premature failure. We |

|

recommend that you lubricate the chain every 15 |

|

Page 20