The parallel guide (accessory) can be used for routing parallel to the edge of the work- piece.

–Secure both guide rods (9.2) with the two rotary knobs (9.3) on the side stop.

–Insert the guide rods into the grooves on the router base to the required distance and secure them by turning the rotary knob (9.4).

Fine adjustment:

–Unscrew the rotary knob (9.5) to make fine adjustments with the adjusting wheel (9.7). The scale ring (9.6) has a 0.1 mm scale for this purpose. If the adjusting wheel is held secure, the scale ring can be turned separately and set to „Zero“. The millime- tre scale (9.1) on the main casing is useful when making larger adjustments. Tighten the rotary knob (9.5) again on completion of any fine adjustments.

–Adjust both guidance jaws (9.8) so that they are approx. 5 mm from the router. To do this, undo screws (9.9) and tighten again after completing the adjustments.

–Slide the extractor hood (9.10) from behind until it latches into place on the side stop. You can connect an extractor hose with a diameter of 27 mm or 36 mm to the extrac- tor connector (9.11).

Routing with the FS

guide system

The guide system (accessory) facilitates rout- ing straight grooves.

10.1

front edge of the guide rail and cutter or groove is observed.

–Place the guide stop onto the guide rail as shown in Fig. 10. To ensure a backlash- free guidance of the router stop you can adjust two guide cheeks with a screwdriver through the side openings (10.2).

–Screw the

When working with

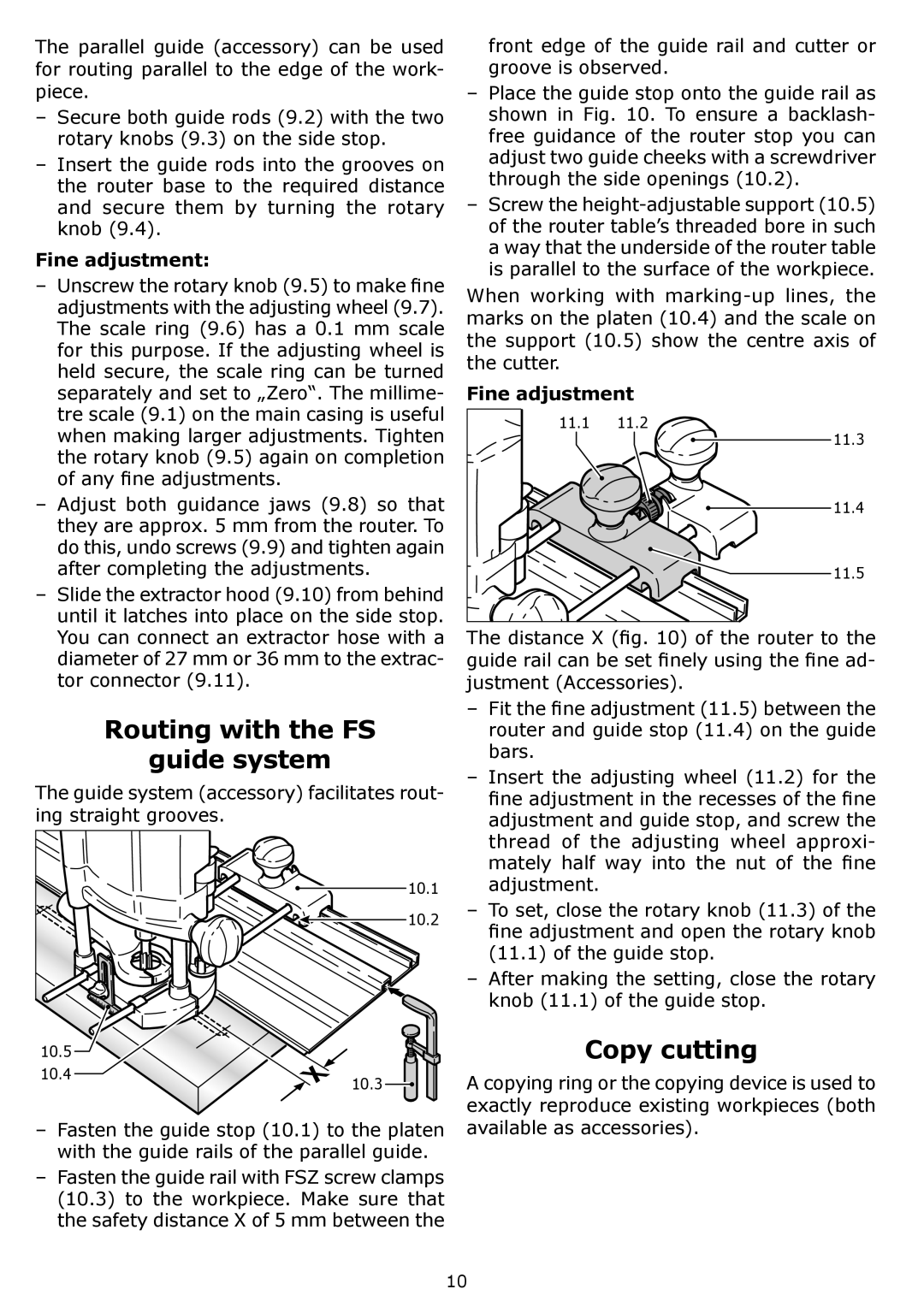

Fine adjustment | |

11.1 | 11.2 |

| 11.3 |

| 11.4 |

| 11.5 |

The distance X (fig. 10) of the router to the guide rail can be set finely using the fine ad- justment (Accessories).

–Fit the fine adjustment (11.5) between the router and guide stop (11.4) on the guide bars.

–Insert the adjusting wheel (11.2) for the fine adjustment in the recesses of the fine adjustment and guide stop, and screw the thread of the adjusting wheel approxi- mately half way into the nut of the fine adjustment.

10.2– To set, close the rotary knob (11.3) of the fine adjustment and open the rotary knob

|

| (11.1) of the guide stop. |

|

| – After making the setting, close the rotary |

|

| knob (11.1) of the guide stop. |

10.5 |

| Copy cutting |

10.4 | 10.3 | A copying ring or the copying device is used to |

|

exactly reproduce existing workpieces (both

– Fasten the guide stop (10.1) to the platen available as accessories). with the guide rails of the parallel guide.

–Fasten the guide rail with FSZ screw clamps (10.3) to the workpiece. Make sure that the safety distance X of 5 mm between the

10