Note: the spindle lock only blocks the mo- tor spindle in one direction of rotation at any one time. Therefore when the nut is undone

5.1 | or tightened, the wrench does not need to be |

offset but can be moved back and forth like a ratchet.

5.2![]()

Installation is similar to that of the copying ring (see fig. 12).

The hood can be cut off along the grooves (5.2) using a hacksaw and can thus be re- duced in size. The chip catcher can then be used for interior radiuses up to a minimum radius of 40 mm.

Clamping collet changing

–Press the switch (6.1) for locking the spin- dle on the

–Press the switch (6.1) for locking the spin- dle on the

Milling cutters

![]() Do not exceed the maximum speed specified on the tool and/or keep to the speed range. Cracked or distorted cutters must not be used.

Do not exceed the maximum speed specified on the tool and/or keep to the speed range. Cracked or distorted cutters must not be used.

6.3

6.2

6.1

B A

You can turn the machine upside down when changing the tool.

Inserting the tool

–Insert the router (6.3) into the open clamp- ing collet as far as possible, but at least up to the mark ![]() on the router shank.

on the router shank.

–Press the switch (6.1) for locking the spin- dle on the

–Tighten the locking nut (6.2) with a 19 mm

Removing the tool

–Press the switch (6.1) for locking the spin- dle on the

–Undo the nut (6.2) using an

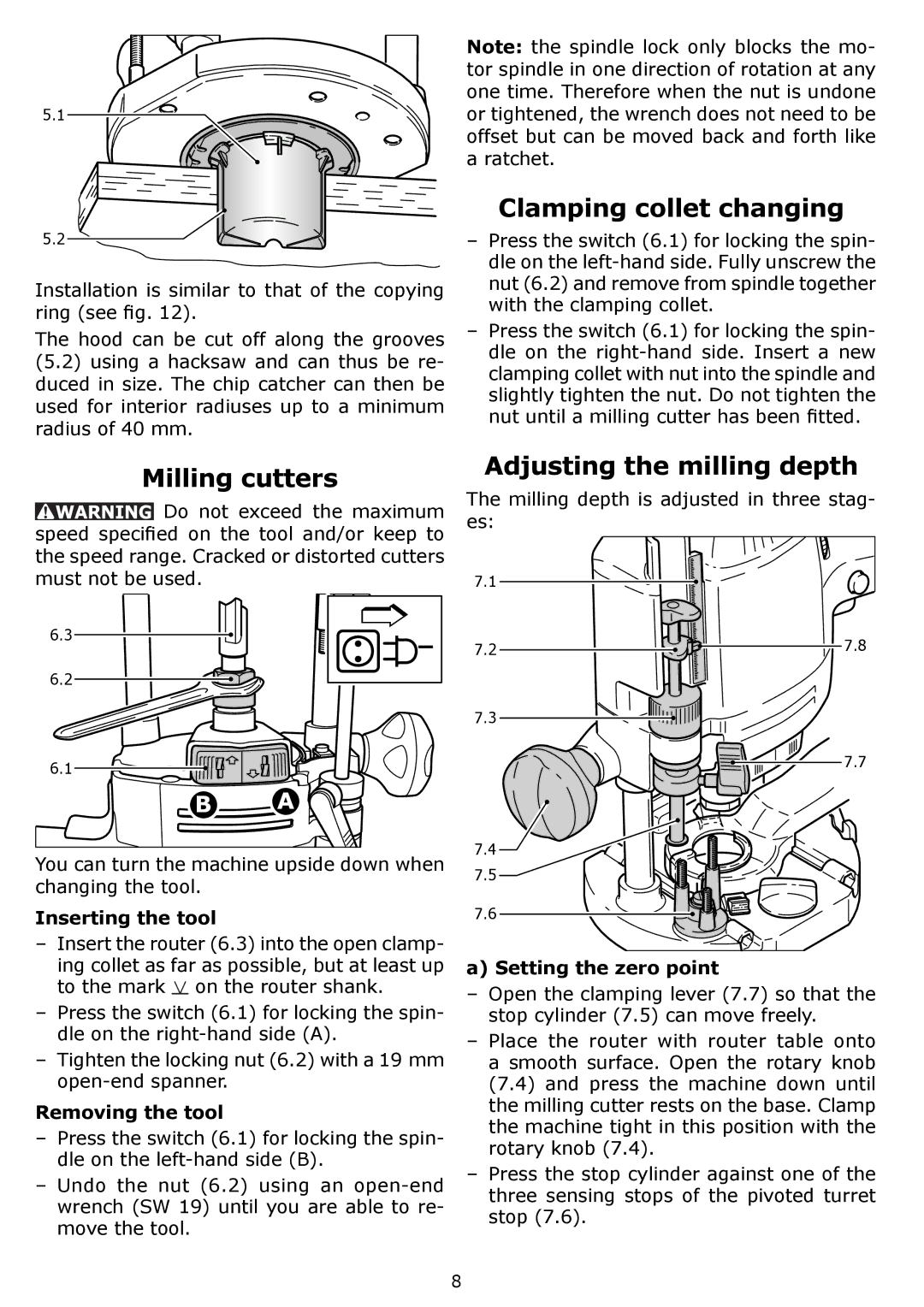

Adjusting the milling depth

The milling depth is adjusted in three stag- es:

7.1

7.2 | 7.8 |

7.3

7.7

7.4

7.5

7.6

a) Setting the zero point

–Open the clamping lever (7.7) so that the stop cylinder (7.5) can move freely.

–Place the router with router table onto a smooth surface. Open the rotary knob (7.4) and press the machine down until the milling cutter rests on the base. Clamp the machine tight in this position with the rotary knob (7.4).

–Press the stop cylinder against one of the three sensing stops of the pivoted turret stop (7.6).

8