3.1Constant speed:

![]()

![]() 3.2 3.3

3.2 3.3

3.4 ![]()

![]() After the machine has been switched off, the milling cutter will still rotate for a time. Take care that parts of your body do not come into contact with the milling cut- ter while it is still rotating!

After the machine has been switched off, the milling cutter will still rotate for a time. Take care that parts of your body do not come into contact with the milling cut- ter while it is still rotating!

Tool settings

![]() Always disconnect the plug from the power supply before making any adjust- ments to the router or installing or removing any accessory!

Always disconnect the plug from the power supply before making any adjust- ments to the router or installing or removing any accessory!

Electronic control

The router OF 1400 EQ has solid shaft elec- tronics with the following functions:

Smooth start-up:

The electronically controlled smooth start- up facility enables

Speed regulation:

Using the electronic speed control (1.1) the motor speed can be continuously adjusted from 10000 and 22500 rpm. The table below offers a guide to the correct electronic set- ting for various materials. The settings are naturally infinitely variable.

Material | Cutter diameter [mm] | Cutter | ||||

|

| material | ||||

|

| |||||

|

|

| ||||

|

|

|

|

|

|

|

Hard wood |

|

| HW/HSS | |||

|

|

|

|

|

|

|

Soft wood |

|

| HSS/HW | |||

|

|

|

|

|

|

|

Panels |

|

| HW | |||

|

|

|

|

|

|

|

Plastic |

|

| HW | |||

|

|

|

|

|

|

|

Aluminium |

|

| HSS/HW | |||

|

|

|

|

|

|

|

Plaster- |

| 1 |

| 1 | HW | |

board |

|

|

|

|

|

|

The selected motor speed is electronically maintained to a constant level. By this means a uniform cutting speed is achieved.

![]() Do not work with the OF 1400 EQ if the electronic control is defective since this may lead to excessive speeds. A defect in the electronic control is indicated by the absence of a smooth

Do not work with the OF 1400 EQ if the electronic control is defective since this may lead to excessive speeds. A defect in the electronic control is indicated by the absence of a smooth

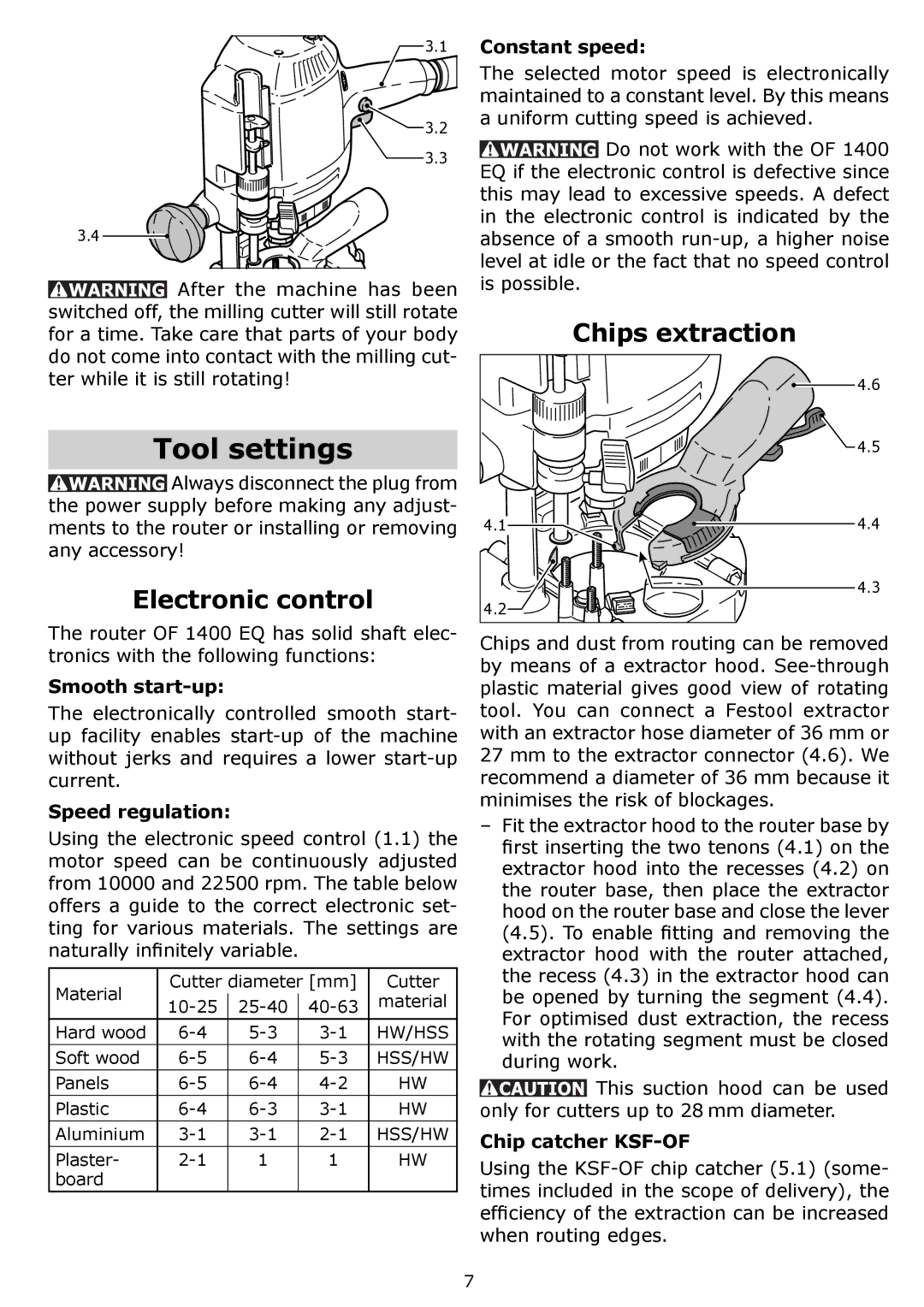

Chips extraction

| 4.6 |

| 4.5 |

4.1 | 4.4 |

| 4.3 |

4.2 |

|

Chips and dust from routing can be removed by means of a extractor hood.

–Fit the extractor hood to the router base by first inserting the two tenons (4.1) on the extractor hood into the recesses (4.2) on the router base, then place the extractor hood on the router base and close the lever (4.5). To enable fitting and removing the extractor hood with the router attached, the recess (4.3) in the extractor hood can be opened by turning the segment (4.4). For optimised dust extraction, the recess with the rotating segment must be closed during work.

![]() This suction hood can be used only for cutters up to 28 mm diameter.

This suction hood can be used only for cutters up to 28 mm diameter.

Chip catcher KSF-OF

Using the

7