– The individual height of each sensing stop | |||

can be adjusted with a screwdriver. | |||

Sensing stop |

| min. height | max. height |

| A | 47 mm | 60 mm |

C B A | B | 53 mm | 74 mm |

| C | 60 mm | 86 mm |

– Push the pointer (7.2) down so that it shows | |||

0 mm on the scale (7.1). |

| ||

If the base position is incorrect, this can be adjusted with the screw (7.8) on the indica- tor.

b) Setting the milling depth

The desired milling depth can be set either with the quick depth adjustment or with the fine depth adjustment.

Quick depth adjustment:

–Pull the stop cylinder (7.5) up until the pointer shows the desired milling depth. Clamp the stop cylinder in this position with the clamping lever (7.7).

Fine depth adjustment:

–Clamp the stop cylinder with the clamping lever (7.7). Set the desired milling depth by turning the adjusting wheel (7.3) in. Turn the adjusting wheel to the next mark on the scale to adjust the milling depth by 0.1 mm. One full turn adjusts the milling depth by 1 mm. The maximum adjustment range with the adjusting wheel is 8 mm.

c) Increasing the milling depth

–Open the rotary knob (7.4) and press the tool down until the stop cylinder touches the sensing stops.

–Clamp the machine in this position by tight- ening the rotary knob (7.4).

Working with the router

![]() Always secure the workpiece in such a manner that it cannot move while being sawed.

Always secure the workpiece in such a manner that it cannot move while being sawed.

![]() The machine must always be

The machine must always be

held with both hands by the designated handles.

![]()

![]()

![]()

![]()

![]()

![]()

![]() Always switch the router on first

Always switch the router on first

before bringing the tool into contact with the workpiece!

Always advance the router in

the same direction as the cutting direction of the cutter

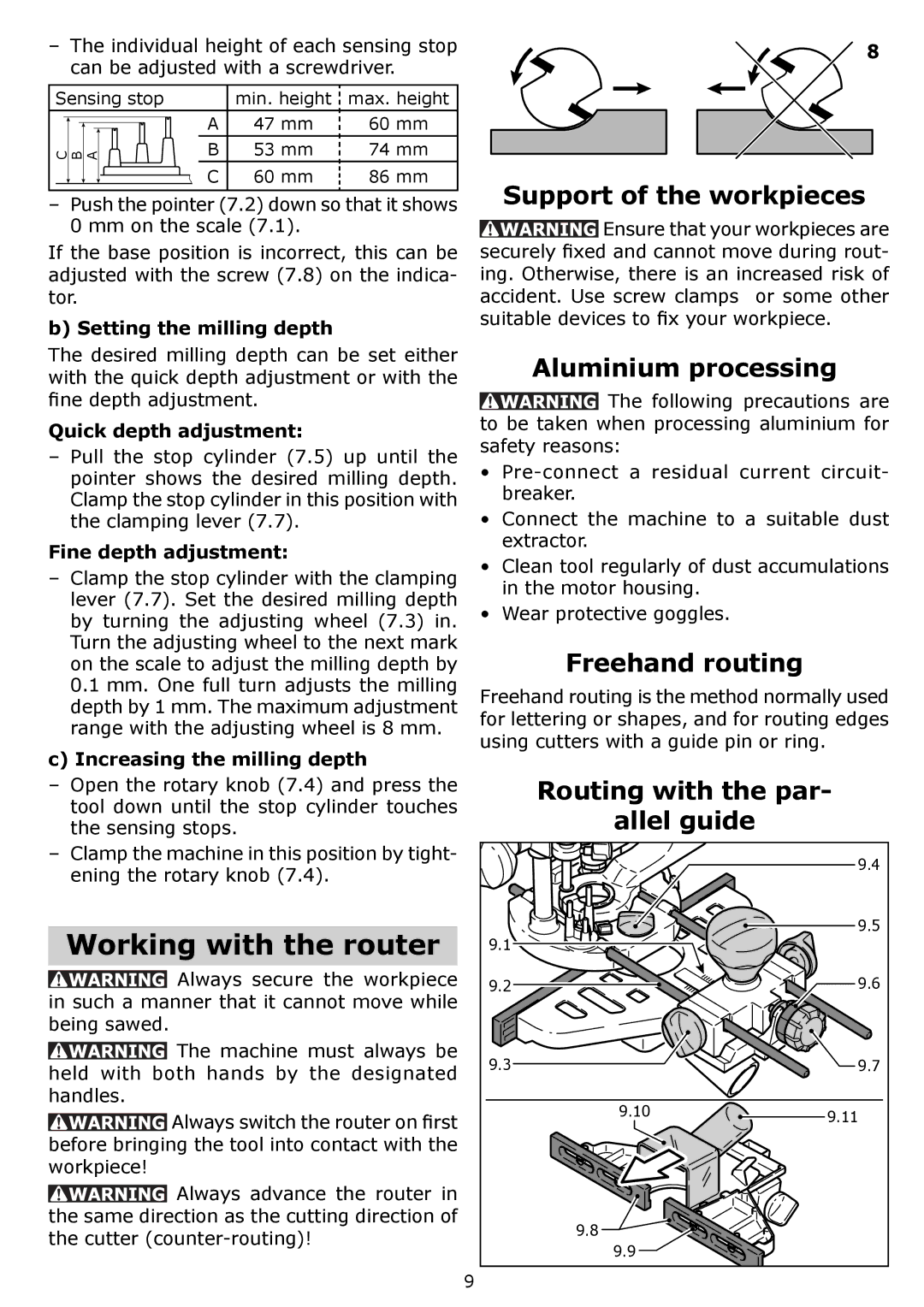

8 |

Support of the workpieces

![]() Ensure that your workpieces are securely fixed and cannot move during rout- ing. Otherwise, there is an increased risk of accident. Use screw clamps or some other suitable devices to fix your workpiece.

Ensure that your workpieces are securely fixed and cannot move during rout- ing. Otherwise, there is an increased risk of accident. Use screw clamps or some other suitable devices to fix your workpiece.

Aluminium processing

![]() The following precautions are to be taken when processing aluminium for safety reasons:

The following precautions are to be taken when processing aluminium for safety reasons:

•

•Connect the machine to a suitable dust extractor.

•Clean tool regularly of dust accumulations in the motor housing.

•Wear protective goggles.

Freehand routing

Freehand routing is the method normally used for lettering or shapes, and for routing edges using cutters with a guide pin or ring.

Routing with the par-

allel guide

|

| 9.4 |

|

| 9.5 |

9.1 |

|

|

9.2 |

| 9.6 |

9.3 |

| 9.7 |

| 9.10 | 9.11 |

|

| |

| 9.8 |

|

| 9.9 |

|

9