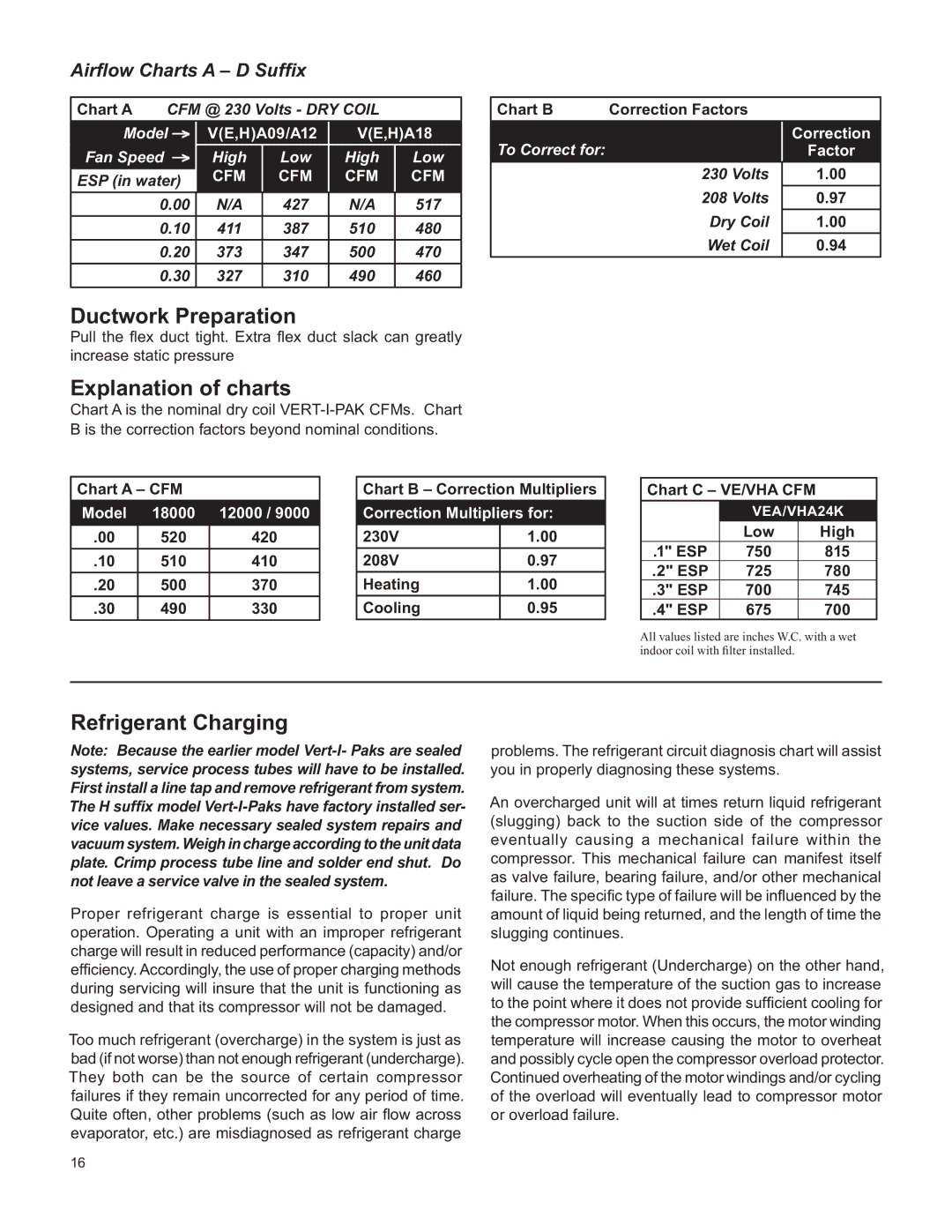

Airflow Charts A – D Suffix

Chart A | CFM @ 230 Volts - DRY COIL |

| ||||

Model | — | V(E,H)A09/A12 | V(E,H)A18 | |||

> | ||||||

Fan Speed | — | High | Low | High | Low | |

> | ||||||

ESP (in water) | CFM | CFM | CFM | CFM | ||

| 0.00 | N/A | 427 | N/A | 517 | |

| 0.10 | 411 | 387 | 510 | 480 | |

| 0.20 | 373 | 347 | 500 | 470 | |

| 0.30 | 327 | 310 | 490 | 460 | |

Chart B | Correction Factors |

|

To Correct for: |

| Correction |

| Factor | |

| 230 Volts | 1.00 |

| 208 Volts | 0.97 |

| Dry Coil | 1.00 |

| Wet Coil | 0.94 |

Ductwork Preparation

Pull the fl ex duct tight. Extra fl ex duct slack can greatly increase static pressure

Explanation of charts

Chart A is the nominal dry coil

Chart A – CFM

Model | 18000 | 12000 / 9000 |

.00 | 520 | 420 |

.10 | 510 | 410 |

.20 | 500 | 370 |

.30 | 490 | 330 |

Chart B – Correction Multipliers

Correction Multipliers for:

230V | 1.00 |

208V | 0.97 |

Heating | 1.00 |

Cooling | 0.95 |

Chart C – VE/VHA CFM

| VEA/VHA24K | |

| Low | High |

.1" ESP | 750 | 815 |

.2" ESP | 725 | 780 |

.3" ESP | 700 | 745 |

.4" ESP | 675 | 700 |

All values listed are inches W.C. with a wet indoor coil with filter installed.

Refrigerant Charging

Note: Because the earlier model

Proper refrigerant charge is essential to proper unit operation. Operating a unit with an improper refrigerant charge will result in reduced performance (capacity) and/or efficiency. Accordingly, the use of proper charging methods during servicing will insure that the unit is functioning as designed and that its compressor will not be damaged.

Too much refrigerant (overcharge) in the system is just as bad (if not worse) than not enough refrigerant (undercharge). They both can be the source of certain compressor failures if they remain uncorrected for any period of time. Quite often, other problems (such as low air fl ow across evaporator, etc.) are misdiagnosed as refrigerant charge

problems. The refrigerant circuit diagnosis chart will assist you in properly diagnosing these systems.

An overcharged unit will at times return liquid refrigerant (slugging) back to the suction side of the compressor eventually causing a mechanical failure within the compressor. This mechanical failure can manifest itself as valve failure, bearing failure, and/or other mechanical failure. The specifi c type of failure will be infl uenced by the amount of liquid being returned, and the length of time the slugging continues.

Not enough refrigerant (Undercharge) on the other hand, will cause the temperature of the suction gas to increase to the point where it does not provide suffi cient cooling for the compressor motor. When this occurs, the motor winding temperature will increase causing the motor to overheat and possibly cycle open the compressor overload protector. Continued overheating of the motor windings and/or cycling of the overload will eventually lead to compressor motor or overload failure.

16