Single Phase Resistance Test

Remove the leads from the compressor terminals and set the ohmmeter on the lowest scale (R x 1).

Touch the leads of the ohmmeter from terminals common to start ("C" to "S"). Next, touch the leads of the ohmmeter from terminals common to run ("C" to "R").

Add values "C" to "S" and "C" to "R" together and check resis- tance from start to run terminals ("S" to "R"). Resistance "S" to "R" should equal the total of "C" to "S" and "C" to "R."

In a single phase PSC compressor motor, the highest value will be from the start to the run connections (“S” to "R"). The next highest resistance is from the start to the common con- nections ("S" to "C"). The lowest resistance is from the run to common. ("C" to "R") Before replacing a compressor, check to be sure it is defective.

Check the complete electrical system to the compressor and compressor internal electrical system, check to be certain that compressor is not out on internal overload.

Complete evaluation of the system must be made whenever you suspect the compressor is defective. If the compressor has been operating for sometime, a careful examination must be made to determine why the compressor failed.

Many compressor failures are caused by the following condi- tions.

1.Improper air flow over the evaporator.

2.Overcharged refrigerant system causing liquid to be re- turned to the compressor.

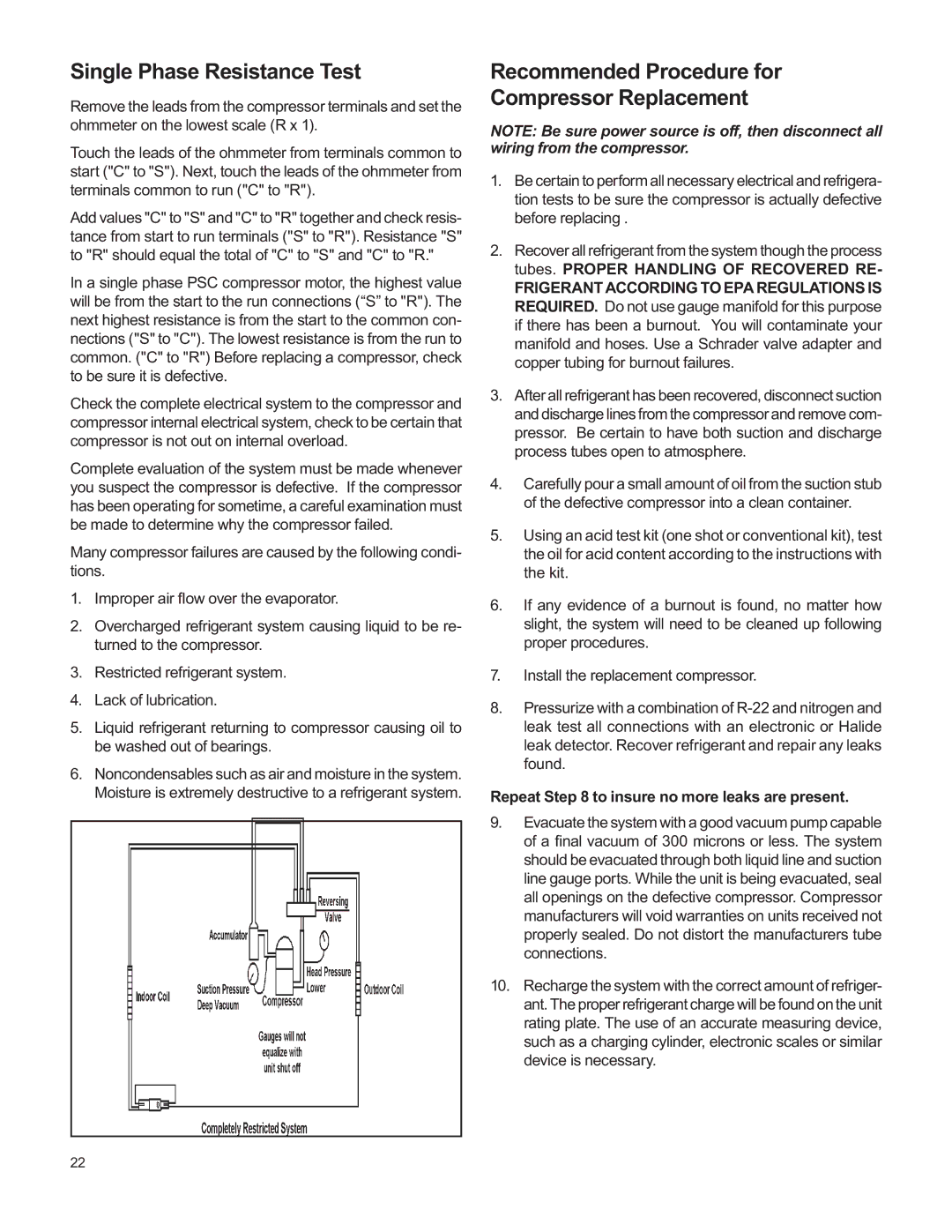

3.Restricted refrigerant system.

4.Lack of lubrication.

5.Liquid refrigerant returning to compressor causing oil to be washed out of bearings.

6.Noncondensables such as air and moisture in the system. Moisture is extremely destructive to a refrigerant system.

Recommended Procedure for

Compressor Replacement

NOTE: Be sure power source is off, then disconnect all wiring from the compressor.

1.Be certain to perform all necessary electrical and refrigera- tion tests to be sure the compressor is actually defective before replacing .

2.Recover all refrigerant from the system though the process tubes. PROPER HANDLING OF RECOVERED RE-

FRIGERANT ACCORDING TO EPA REGULATIONS IS REQUIRED. Do not use gauge manifold for this purpose if there has been a burnout. You will contaminate your manifold and hoses. Use a Schrader valve adapter and copper tubing for burnout failures.

3.After all refrigerant has been recovered, disconnect suction and discharge lines from the compressor and remove com- pressor. Be certain to have both suction and discharge process tubes open to atmosphere.

4.Carefully pour a small amount of oil from the suction stub of the defective compressor into a clean container.

5.Using an acid test kit (one shot or conventional kit), test the oil for acid content according to the instructions with the kit.

6.If any evidence of a burnout is found, no matter how slight, the system will need to be cleaned up following proper procedures.

7.Install the replacement compressor.

8.Pressurize with a combination of

Repeat Step 8 to insure no more leaks are present.

9.Evacuate the system with a good vacuum pump capable of a final vacuum of 300 microns or less. The system should be evacuated through both liquid line and suction line gauge ports. While the unit is being evacuated, seal all openings on the defective compressor. Compressor manufacturers will void warranties on units received not properly sealed. Do not distort the manufacturers tube connections.

10.Recharge the system with the correct amount of refriger- ant. The proper refrigerant charge will be found on the unit rating plate. The use of an accurate measuring device, such as a charging cylinder, electronic scales or similar device is necessary.

22