Checking Reversing Valve

NOTE: You must have normal operating pressures before the reversing valve can shift.

Check for proper refrigerant charge. Sluggish or sticky reversing valves can sometimes be remedied by reversing the valve several time with the airflow restricted to increase system pressure.

To raise head pressure during the cooling season the airflow through the outdoor coil can be restricted . During heating the indoor air can be restricted by blocking the return air.

Dented or damaged valve body or capillary tubes can prevent the main slide in the valve body from shifting.

If you determine this is the problem, replace the reversing valve.

After all of the previous inspections and checks have been made and determined correct, then perform the “Touch Test” on the reversing valve.

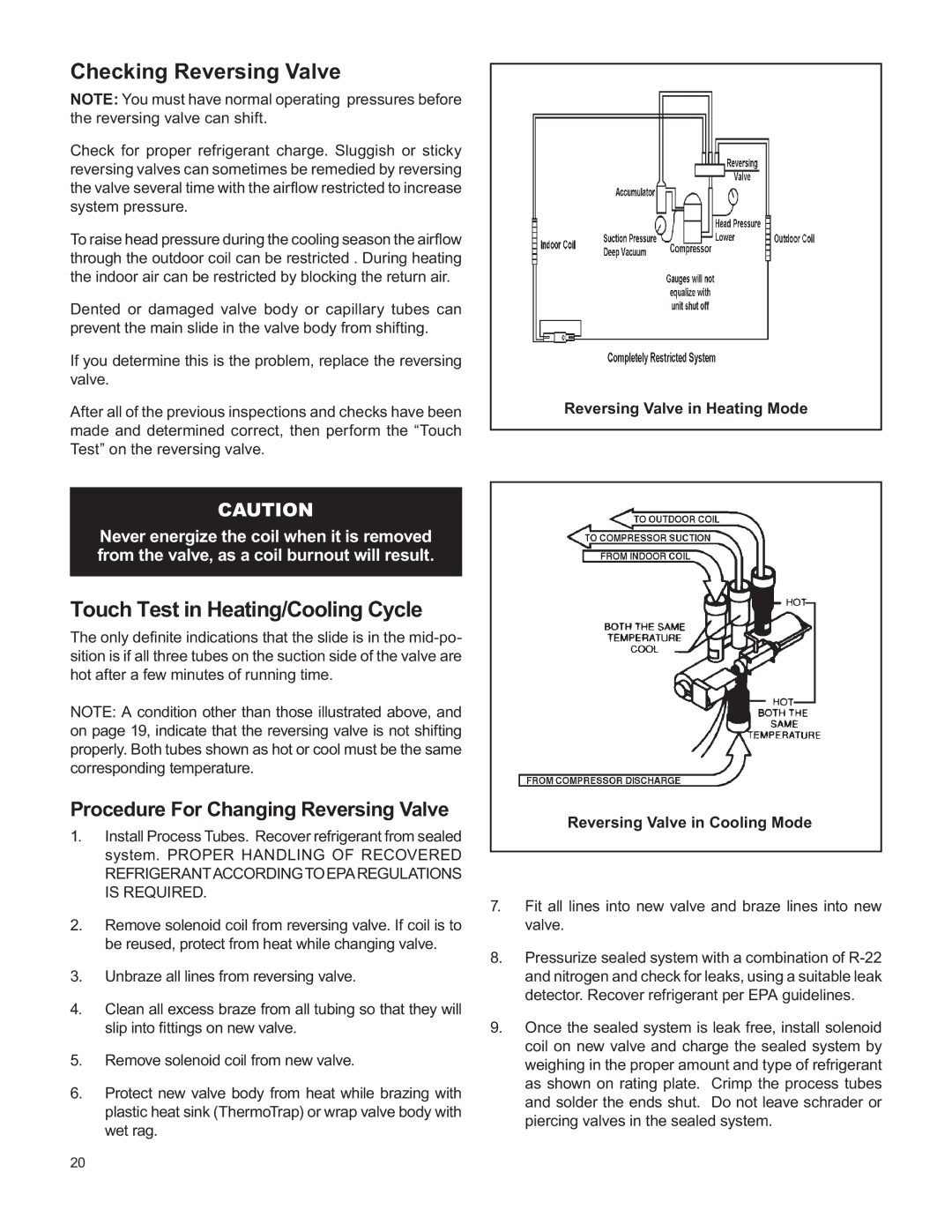

Reversing Valve in Heating Mode

CAUTION

Never energize the coil when it is removed from the valve, as a coil burnout will result.

Touch Test in Heating/Cooling Cycle

The only definite indications that the slide is in the

NOTE: A condition other than those illustrated above, and on page 19, indicate that the reversing valve is not shifting properly. Both tubes shown as hot or cool must be the same corresponding temperature.

Procedure For Changing Reversing Valve

1.Install Process Tubes. Recover refrigerant from sealed system. PROPER HANDLING OF RECOVERED REFRIGERANTACCORDINGTOEPAREGULATIONS IS REQUIRED.

2.Remove solenoid coil from reversing valve. If coil is to be reused, protect from heat while changing valve.

3.Unbraze all lines from reversing valve.

4.Clean all excess braze from all tubing so that they will slip into fittings on new valve.

5.Remove solenoid coil from new valve.

6.Protect new valve body from heat while brazing with plastic heat sink (ThermoTrap) or wrap valve body with wet rag.

Reversing Valve in Cooling Mode

7.Fit all lines into new valve and braze lines into new valve.

8.Pressurize sealed system with a combination of

9.Once the sealed system is leak free, install solenoid coil on new valve and charge the sealed system by weighing in the proper amount and type of refrigerant as shown on rating plate. Crimp the process tubes and solder the ends shut. Do not leave schrader or piercing valves in the sealed system.

20