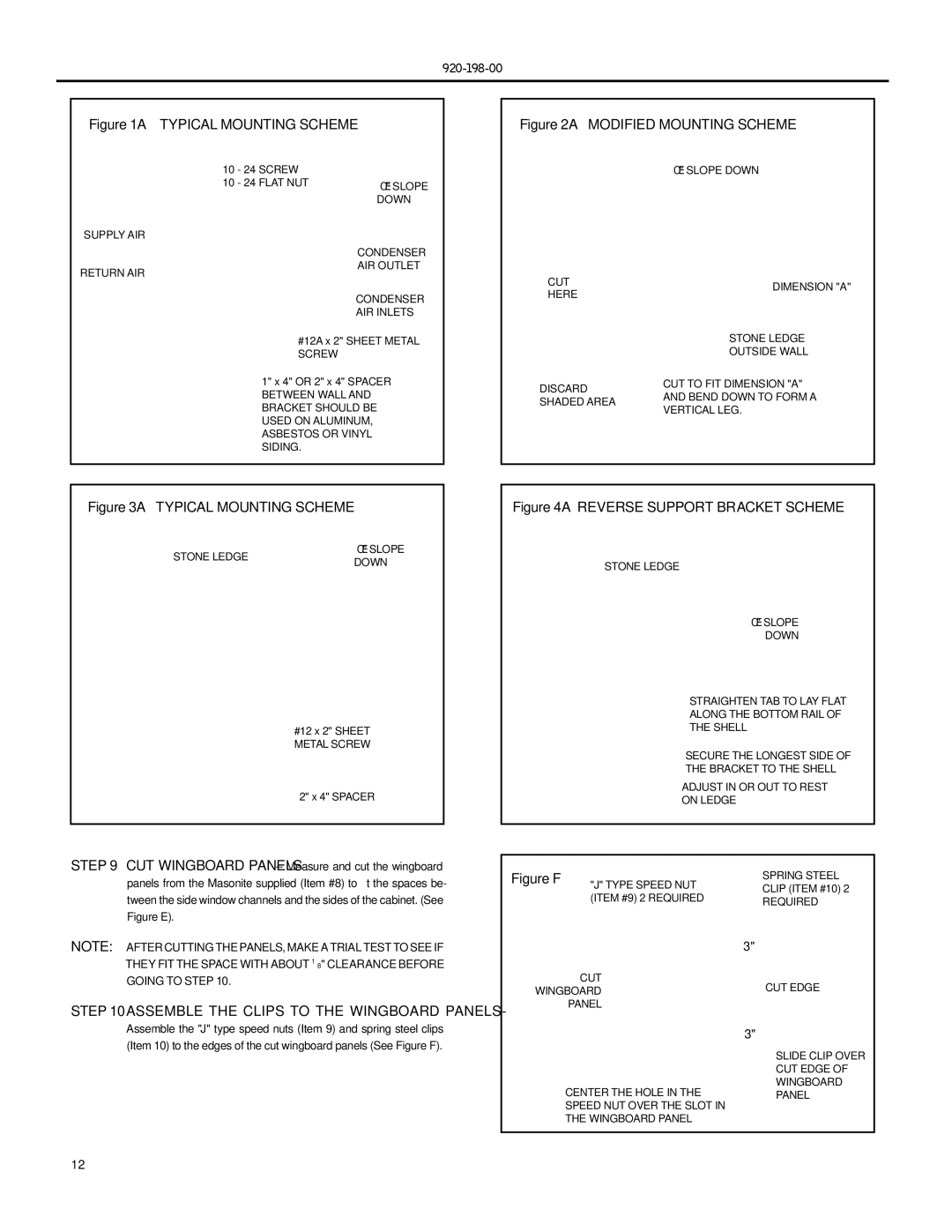

Figure 1A TYPICAL MOUNTING SCHEME

Figure 2A MODIFIED MOUNTING SCHEME

SUPPLY AIR

RETURN AIR

10 - 24 SCREW

10 - 24 FLAT NUT⅜" SLOPE DOWN

CONDENSER

AIR OUTLET

CONDENSER

AIR INLETS

#12A x 2" SHEET METAL SCREW

1" x 4" OR 2" x 4" SPACER BETWEEN WALL AND BRACKET SHOULD BE USED ON ALUMINUM, ASBESTOS OR VINYL SIDING.

CUT

HERE

DISCARD SHADED AREA

⅜" SLOPE DOWN

DIMENSION "A"

STONE LEDGE

OUTSIDE WALL

CUT TO FIT DIMENSION "A" AND BEND DOWN TO FORM A VERTICAL LEG.

Figure 3A TYPICAL MOUNTING SCHEME

STONE LEDGE | ⅜" SLOPE | |

DOWN | ||

|

#12 x 2" SHEET METAL SCREW

2" x 4" SPACER

Figure 4A REVERSE SUPPORT BRACKET SCHEME

STONE LEDGE

⅜" SLOPE DOWN

STRAIGHTEN TAB TO LAY FLAT

ALONG THE BOTTOM RAIL OF

THE SHELL

SECURE THE LONGEST SIDE OF

THE BRACKET TO THE SHELL

ADJUST IN OR OUT TO REST

ON LEDGE

STEP 9 CUT WINGBOARD PANELS – Measure and cut the wingboard panels from the Masonite supplied (Item #8) to fit the spaces be- tween the side window channels and the sides of the cabinet. (See Figure E).

NOTE: AFTER CUTTING THE PANELS, MAKE A TRIAL TEST TO SEE IF THEY FIT THE SPACE WITH ABOUT 1⁄8" CLEARANCE BEFORE GOING TO STEP 10.

STEP 10 ASSEMBLE THE CLIPS TO THE WINGBOARD PANELS- Assemble the "J" type speed nuts (Item 9) and spring steel clips (Item 10) to the edges of the cut wingboard panels (See Figure F).

Figure F | "J" TYPE SPEED NUT |

| (ITEM #9) 2 REQUIRED |

CUT

WINGBOARD

PANEL

CENTER THE HOLE IN THE

SPEED NUT OVER THE SLOT IN

THE WINGBOARD PANEL

SPRING STEEL

CLIP (ITEM #10) 2

REQUIRED

3"

CUT EDGE

3"

SLIDE CLIP OVER

CUT EDGE OF

WINGBOARD

PANEL

12