INSTALLATION REQUIREMENTS

Electrical requirements for gas dryer

CIRCUIT - Individual, properly polarized and grounded 15 amp. branch circuit fused with 15 amp. time delay fuse or circuit breaker.

POWER SUPPLY -

POWER SUPPLY CORD - The dryer is equipped with a 120 volt

GROUNDING CONNECTION - See “Grounding requirements” in Electrical Installation section.

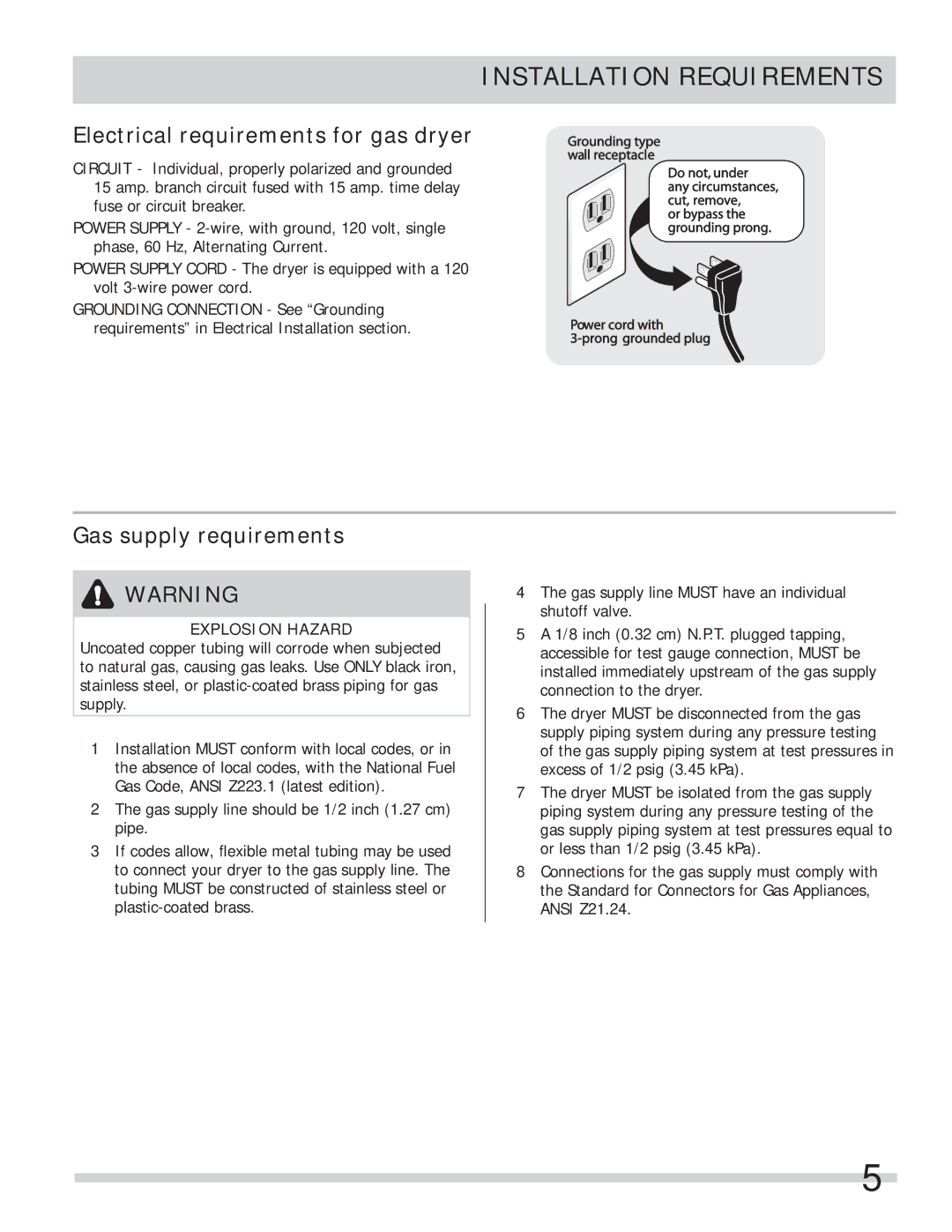

Grounding type wall receptacle

Do not, under

any circumstances, cut, remove,

or bypass the grounding prong.

Power cord with

Gas supply requirements

![]()

![]() WARNING

WARNING

EXPLOSION HAZARD Uncoated copper tubing will corrode when subjected

to natural gas, causing gas leaks. Use ONLY black iron, stainless steel, or

1Installation MUST conform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1 (latest edition).

2The gas supply line should be 1/2 inch (1.27 cm) pipe.

3If codes allow, flexible metal tubing may be used to connect your dryer to the gas supply line. The tubing MUST be constructed of stainless steel or

4The gas supply line MUST have an individual shutoff valve.

5A 1/8 inch (0.32 cm) N.P.T. plugged tapping, accessible for test gauge connection, MUST be installed immediately upstream of the gas supply connection to the dryer.

6The dryer MUST be disconnected from the gas supply piping system during any pressure testing of the gas supply piping system at test pressures in excess of 1/2 psig (3.45 kPa).

7The dryer MUST be isolated from the gas supply piping system during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.45 kPa).

8Connections for the gas supply must comply with the Standard for Connectors for Gas Appliances, ANSI Z21.24.

5