auger or drain snake. Compressed air or other pressurized gases should not be used to force out the blockage

1.11 Basket Lift Service Procedures

2836 Series Electric fryers may optionally be equipped with automatic basket lifts to ensure uniform cooking times. Electric fryers can be equipped with "modular" or

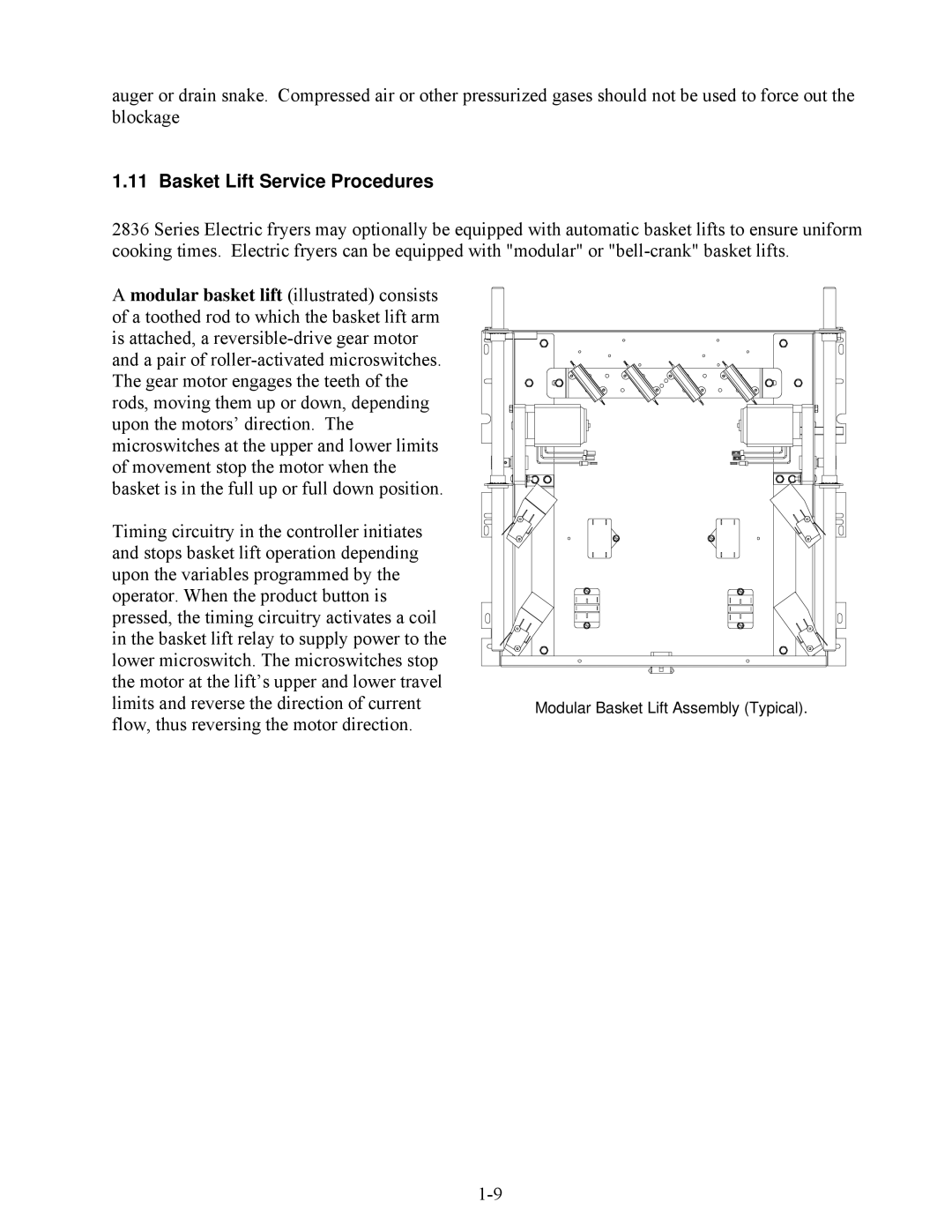

A modular basket lift (illustrated) consists of a toothed rod to which the basket lift arm is attached, a

Timing circuitry in the controller initiates and stops basket lift operation depending upon the variables programmed by the operator. When the product button is pressed, the timing circuitry activates a coil in the basket lift relay to supply power to the lower microswitch. The microswitches stop the motor at the lift’s upper and lower travel

limits and reverse the direction of currentModular Basket Lift Assembly (Typical). flow, thus reversing the motor direction.